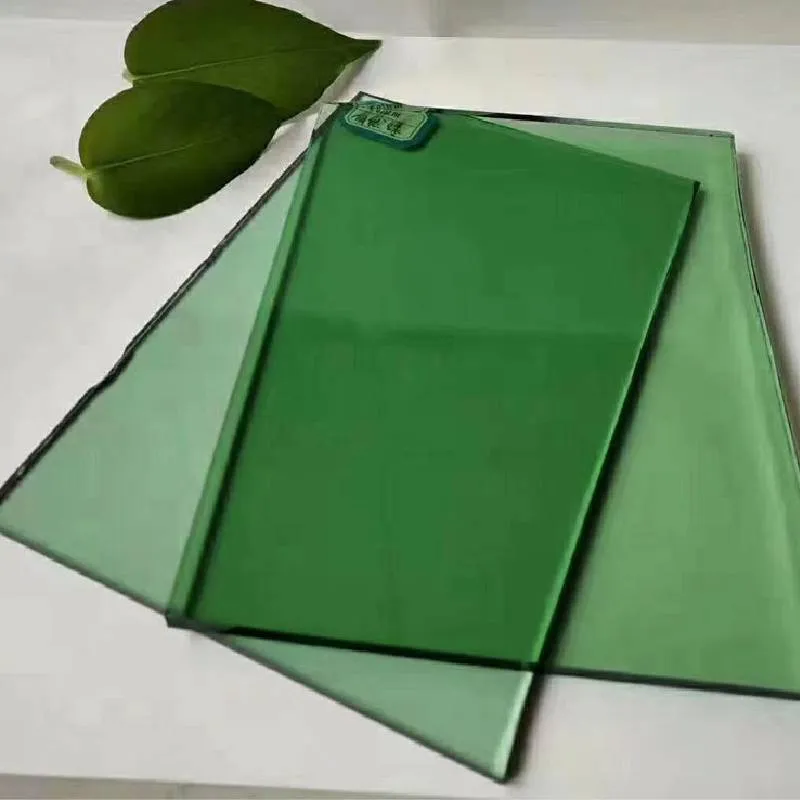

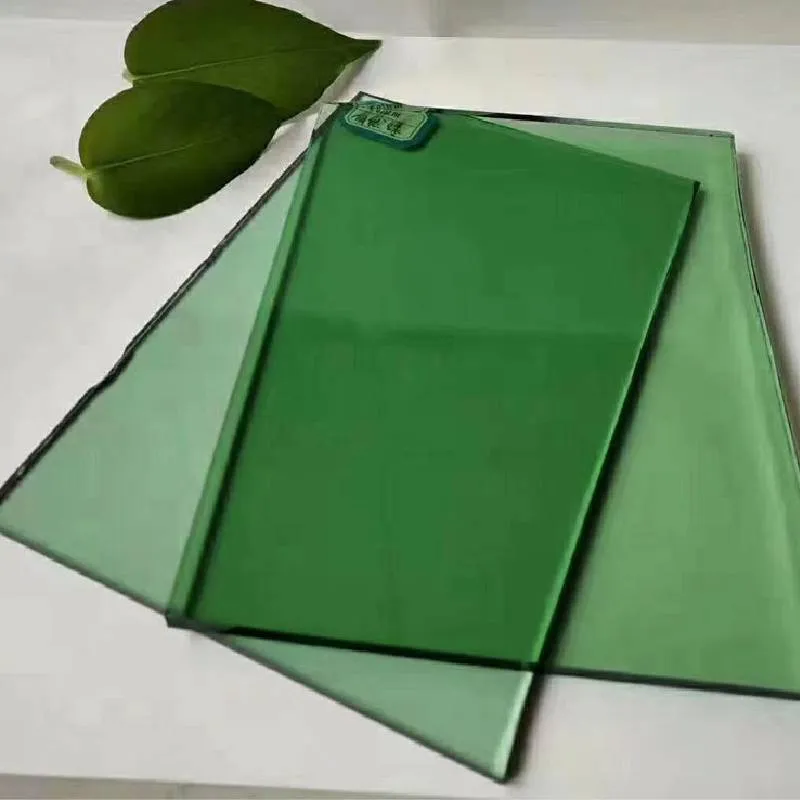

5mm float glass might seem like an ordinary product at first glance, yet it holds remarkable potential across various industries due to its versatility and quality. As a key component in architecture and automotive sectors, its unique properties offer unparalleled benefits that contribute significantly to both structural projects and design innovations.

One of the most compelling aspects of 5mm float glass is its pristine clarity and smooth surface, achieved through a meticulous manufacturing process. This involves floating molten glass on a bed of molten tin, resulting in flat,

uniform glass. The consistency in thickness makes it an ideal choice for applications requiring visual clarity and aesthetic appeal, such as in storefront windows or glass facades in architectural designs. The transparency it offers not only invites natural light but also enhances the visual connectivity between indoor and outdoor spaces, thereby contributing to energy efficiency by reducing reliance on artificial lighting.

Experts in architecture praise 5mm float glass for its adaptability to various design aesthetics. Its capacity for cut-to-size customization allows it to fit specific design requirements, making it an essential element for bespoke projects and innovative structural designs. This adaptability extends to its use in interior applications such as partitions, balustrades, and even modern furniture, where its sleek finish complements contemporary styles.

In the automotive industry, 5mm float glass serves as an integral part of vehicle design, particularly in windows and windshields. Automotive experts emphasize its capacity to enhance safety while ensuring passenger comfort through its sound dampening properties. The robustness of float glass contributes to the structural integrity required in vehicles, while its optical clarity ensures unobstructed visibility, crucial for safe driving.

5mm float glass

Moreover, 5mm float glass conforms to various regulatory standards, attesting to its quality and safety. Manufacturers undergo rigorous testing to meet the required norms, ensuring that the glass performs as expected under different conditions. This compliance boosts the trustworthiness of the product, making it a preferred choice among architects and automotive engineers who prioritize safety and reliability.

The production of 5mm float glass also speaks to economic efficiency. With advanced technology, manufacturers have streamlined processes to produce bulk quantities with minimal waste. This cost-effectiveness translates to value for consumers and businesses, as it reduces the overall expenditure while delivering a high-quality product.

Sustainability is an ever-growing concern in today's market, and 5mm float glass aligns with eco-friendly practices. Its lifecycle, from production to installation and eventual recycling, minimizes environmental impact. Modern manufacturers often incorporate recycled glass into their product lines, reducing the demand for raw materials and limiting energy consumption. This commitment to sustainable practices resonates well with environmentally conscious consumers and businesses aiming to reduce their ecological footprint.

As more sectors recognize the advantages of this versatile material, 5mm float glass continues to gain traction as a reliable resource for innovation. Industry professionals and consumers alike appreciate its combination of aesthetic appeal, safety, and sustainability. Whether in a high-rise building, a chic interior design, or the latest vehicle model, 5mm float glass is proving to be an indispensable component, celebrated for its ability to bring clarity, quality, and confidence to every project.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu