The sheet glass manufacturing industry combines a harmonious blend of innovation, precision, and meticulous craftsmanship to create one of the most versatile building materials available. As industry experts, we have seen how advancements in technology have revolutionized glass production techniques, whilst ensuring sustainability and efficiency remain at the forefront.

Drawing from extensive industry experience, the traditional processes, such as the Fourcault method or the Colburn process, have evolved significantly. These methods have been instrumental in shaping the early days of sheet glass production. However, the continuous glass draw processes have now been replaced by the superior Float Glass Process, pioneered by Alastair Pilkington in the mid-20th century, which offers unmatched efficiency and quality.

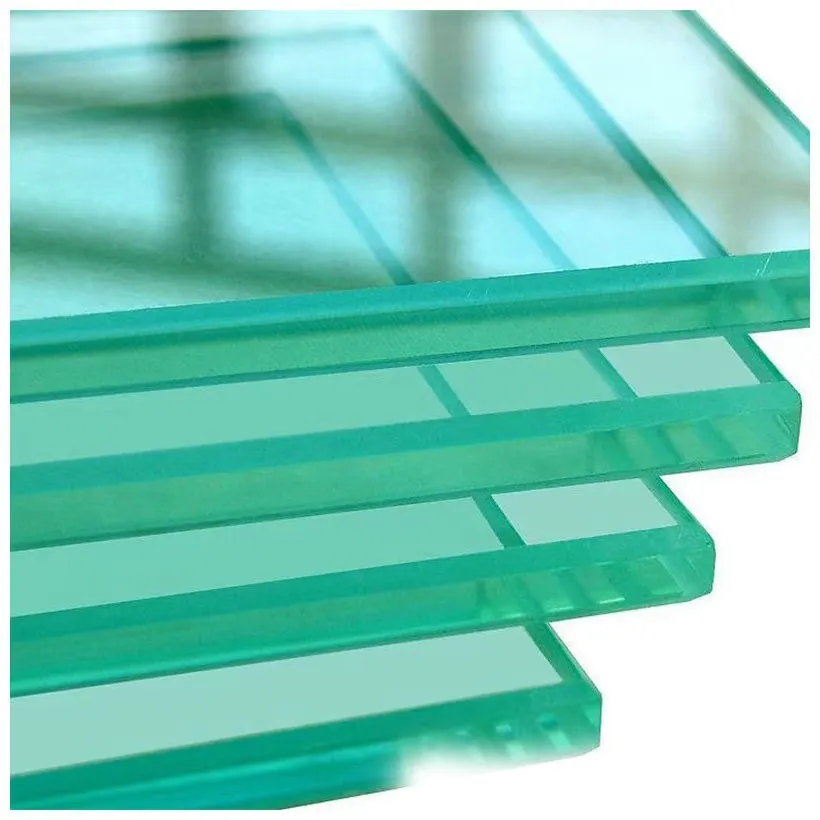

In the Float Glass Process, raw materials like silica sand, soda ash, and limestone are melted at intensely high temperatures. The molten glass is carefully fed onto a bath of molten tin, where it spreads out to form a perfectly flat and uniform sheet. This innovative technique not only ensures almost perfect flatness and uniform thickness but also produces a superior, distortion-free surface—a necessity for modern architectural applications.

As specialists in this domain, we understand that the choice of raw materials and precise control of variables, such as temperature and the chemical composition of the molten glass, are crucial in determining the quality of the final product.

This attention to detail affirms our standing in manufacturing excellence.

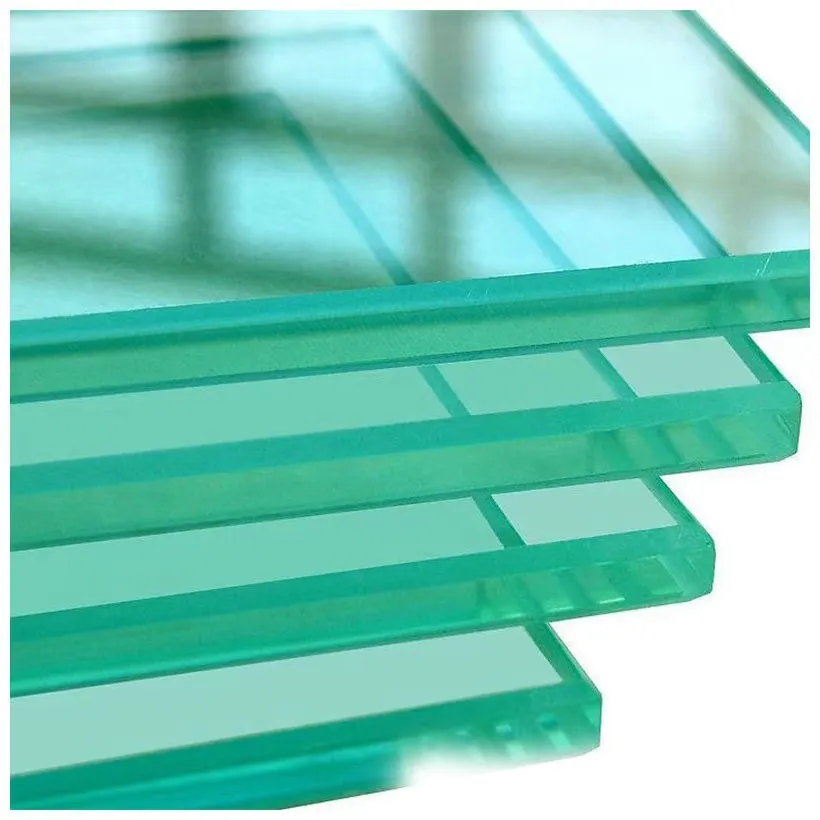

sheet glass manufacturing

In terms of expertise, modern sheet glass manufacturers have adopted cutting-edge technologies to enhance product offerings, including energy-efficient low-E coatings, solar control functionalities, and self-cleaning capabilities. Such innovations align with the global movement toward sustainable building solutions, reducing environmental impact while delivering superior performance. Products like double-glazed or argon-filled glass panes further exemplify our commitment to energy conservation, leading to significant reductions in heating and cooling costs for buildings.

Authoritativeness in the industry is cemented through continuous research and development. Investment in state-of-the-art facilities, together with collaborations with leading research institutions, has driven the advancement of new glass variants—addressing market demands for safety, durability, and aesthetics. Reinforced by quality assurance protocols, rigorous testing regimes ensure that each sheet surpasses international standards for durability, impact resistance, and thermal performance.

Trustworthiness emerges from our dedication to ethical production practices and a transparent supply chain. As stakeholders in environmental sustainability, our production facilities are equipped to recycle heat and reduce waste, while our sourcing strategies ensure minimal ecological disruption. Our adherence to international safety and environmental regulations further underscores our commitment to responsible manufacturing.

In conclusion, sheet glass manufacturing stands as a testament to human ingenuity and the relentless pursuit of excellence. Whether for residential architecture, commercial skyscrapers, or innovative design projects, sheet glass continues to illuminate and inspire, making it the architect's material of choice across a multitude of applications. Our expertise, unwavering quality, and commitment to sustainability position us as leaders in this transformative industry. As we look toward the future, we remain focused on pioneering advancements that deliver both stunning aesthetics and unyielding functionality.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu