The sheet glass manufacturing process has undergone significant technological advancements over the years, establishing itself as a cornerstone in the production of high-quality glass products used in various applications—from architectural structures to intricate electronic displays. Understanding this process not only demystifies the science behind sheet glass but also highlights its role as a crucial component across different industries.

Beginning with the raw materials, sand, soda ash, and limestone are the primary constituents in sheet glass production. These ingredients undergo a precise heating process in a furnace that reaches temperatures above 1700 degrees Celsius. This high-temperature environment ensures the complete melting and homogenization of the mixture, forming a molten glass that can then be molded into sheets.

The evolution of the sheet glass process has been marked by the development of the float glass method, pioneered by Sir Alastair Pilkington in the mid-20th century. This method involves pouring the molten glass onto a bed of molten tin. The unique properties of tin—such as its low melting point and ability to withstand glass without bonding—allow the molten glass to spread evenly, creating a perfectly flat and smooth sheet as it cools. The precision of the float glass process ensures uniform thickness, which is a crucial quality for applications demanding optical clarity and structural integrity.

An alternative to the float method is the rolled glass process, commonly employed for textured glass. This technique uses rollers to imprint patterns as the glass sheet is formed. Although this process doesn't offer the same level of clarity and precision as float glass, it provides design versatility, often used in decorative applications.

Quality control is a critical element in the sheet glass process. Advanced scanning technologies are employed to detect imperfections or impurities at various stages. Any anomalies identified are rectified, ensuring that the end product meets stringent industry standards. This meticulous approach to quality reinforces the durability and reliability of sheet glass, essential for maintaining trust with consumers and stakeholders alike.

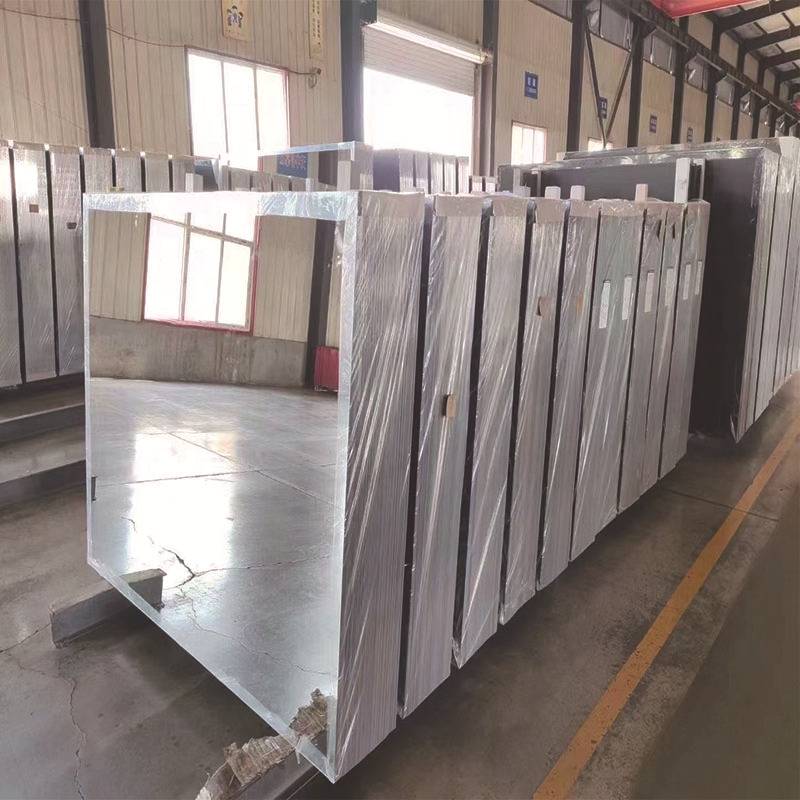

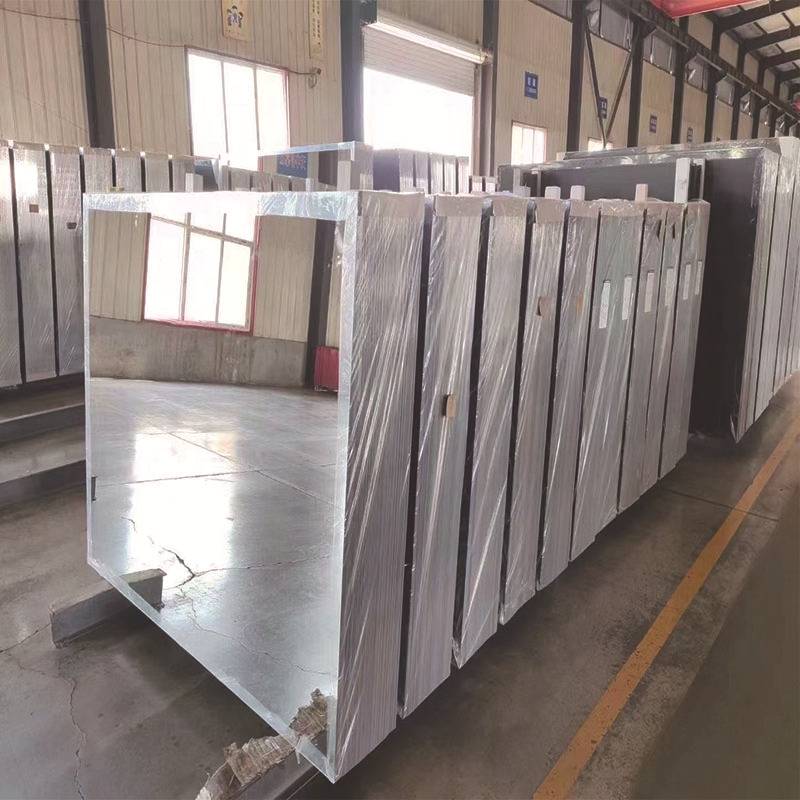

sheet glass process

Furthermore, innovations in coating technologies have expanded the functional possibilities of sheet glass. Through advanced techniques like magnetron sputtering, low-emissivity coatings can be applied to enhance energy efficiency, a key factor in modern architectural design. These coatings significantly reduce heat transfer, contributing to energy-saving objectives in both residential and commercial buildings.

The expertise required in sheet glass production underscores the importance of skilled workforce involvement. Continuous training and development programs are essential to staying abreast of technological advancements and maintaining a competitive edge in the market. This ongoing investment in human capital fosters an environment of expertise and authority, directly impacting the quality of the sheet glass produced.

Trustworthiness in the sheet glass industry is built on a foundation of consistency and compliance with international standards. Certifications such as ISO 9001 for quality management systems are commonly pursued by leading manufacturers, demonstrating a commitment to excellence. This assurance is fundamental in establishing long-term partnerships with clients and consistently meeting the evolving demands of the market.

In summary, the sheet glass process is a sophisticated intersection of chemistry, physics, and innovation, driven by an unwavering commitment to quality and sustainability. As advancements continue to unfold, sheet glass remains an essential material, enabling architectural feats and technological breakthroughs. By adhering to the highest standards of experience, expertise, authoritativeness, and trustworthiness, the industry continues to excel, offering products that not only meet but exceed expectations.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu