The Aluminum Mirror Coating Process An Overview

Aluminum mirror coating is a critical process used in the production of high-quality reflective surfaces for various applications, ranging from astronomy to everyday consumer products. The procedure involves several steps that ensure the final product possesses superior reflective qualities while maintaining durability. This article outlines the key components and considerations involved in the aluminum mirror coating process.

1. Substrate Preparation

The first step in the aluminum mirror coating process is substrate preparation. Common substrates include glass, plastics, or metals, depending on the intended application. The chosen material must undergo thorough cleaning to remove any contaminants such as dust, oils, or fingerprints that could interfere with the bonding of the aluminum layer. Standard cleaning methods involve ultrasonic baths, rinsing with deionized water, and using solvents like isopropyl alcohol.

Once cleaned, the substrate may also be treated to enhance adhesion. This can involve etching the surface or applying a primer that bonds well with both the substrate and the aluminum layer.

2. Vacuum Deposition Techniques

The core of the aluminum mirror coating process is the deposition of aluminum onto the prepared substrate. This is typically done using vacuum deposition techniques, which can include Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD).

Physical Vapor Deposition (PVD) is a widely used method that involves heating aluminum until it vaporizes in a vacuum chamber. The vaporized aluminum then condenses onto the cooler substrate, forming a thin, uniform layer. PVD allows for precise control over the thickness of the aluminum layer, which is crucial for optimizing reflectivity.

Chemical Vapor Deposition (CVD), on the other hand, uses chemical reactions to deposit aluminum compounds, which then convert to aluminum upon reaching the substrate. This method can yield coatings with high uniformity and adhesion strength.

3. Thickness Control

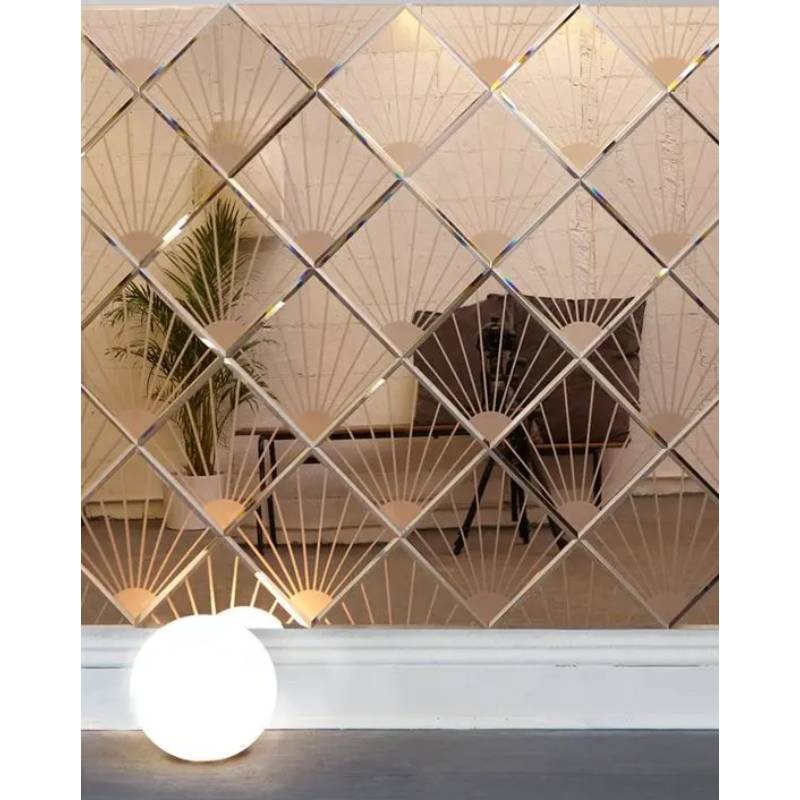

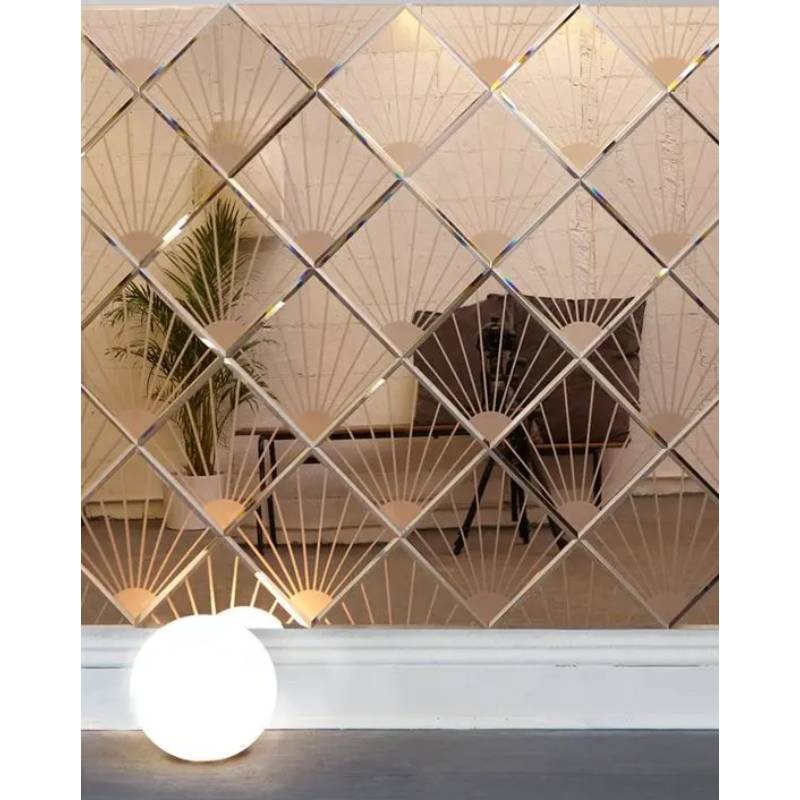

aluminum mirror coating process

One of the critical parameters during the aluminum coating process is the thickness of the aluminum layer. Optimal thickness typically ranges between 100 and 300 nanometers, as this range balances reflectivity with durability. Thicker layers can reflect more light but may also lead to increased stress on the substrate and potential cracking or peeling.

Monitoring techniques, like quartz crystal microbalances or optical reflectance measurement, are used to achieve precise control over the thickness during deposition.

4. Post-Coating Treatments

After the aluminum has been deposited, post-coating treatments are often necessary to enhance the performance of the mirrors. These treatments can include the application of protective coatings that improve scratch resistance, weather resistance, and overall durability. Common protective coatings include silicon dioxide (SiO2) or magnesium fluoride (MgF2), both of which also serve to improve optical performance by minimizing reflection losses.

5. Quality Control and Testing

Quality control is a critical component of the aluminum mirror coating process. Finished mirrors undergo rigorous testing to ensure they meet required specifications. Key characteristics evaluated include reflectivity, durability, and adherence of the coating. Techniques such as spectrophotometry are employed to measure reflectivity across various wavelengths, while mechanical tests assess the strength of the bond between the aluminum layer and the substrate.

6. Applications

Aluminum-coated mirrors have a wide range of applications. In astronomy, they are used in telescopes to enhance light collection from distant celestial bodies. In solar energy applications, aluminum mirrors are essential for concentrating sunlight to optimize energy production. Other applications include lighting fixtures, car headlights, and decorative items.

Conclusion

The aluminum mirror coating process is a sophisticated blend of science and engineering that establishes the foundation for numerous optical technologies. Through careful substrate preparation, controlled deposition methods, and rigorous quality control, manufacturers can produce highly reflective, durable mirrors that meet the diverse needs of various industries. As technology advances, the processes involved in aluminum coating will likely undergo further refinement, paving the way for even more innovative applications in the future.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu