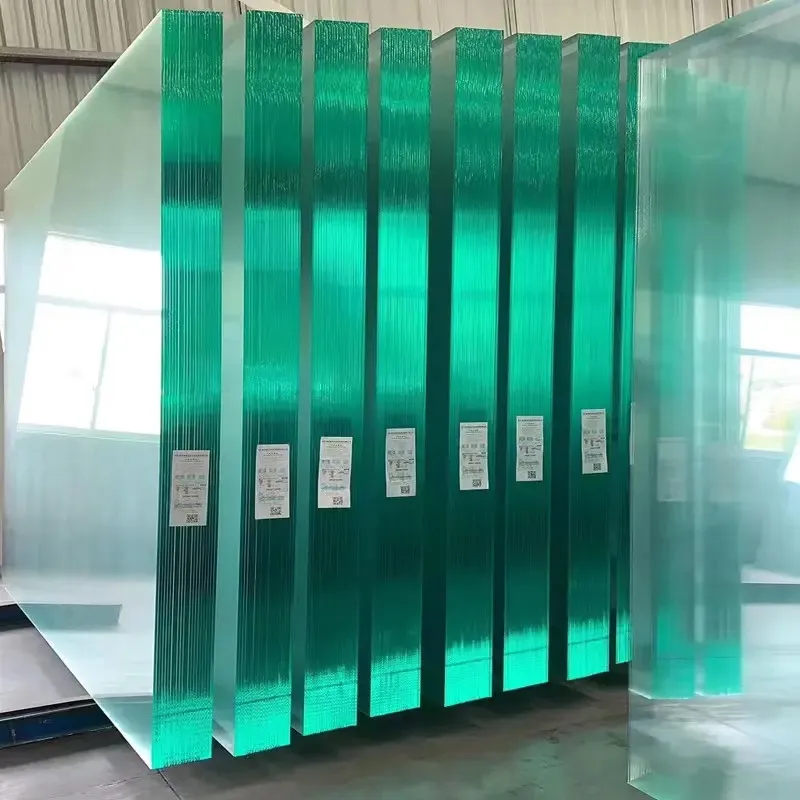

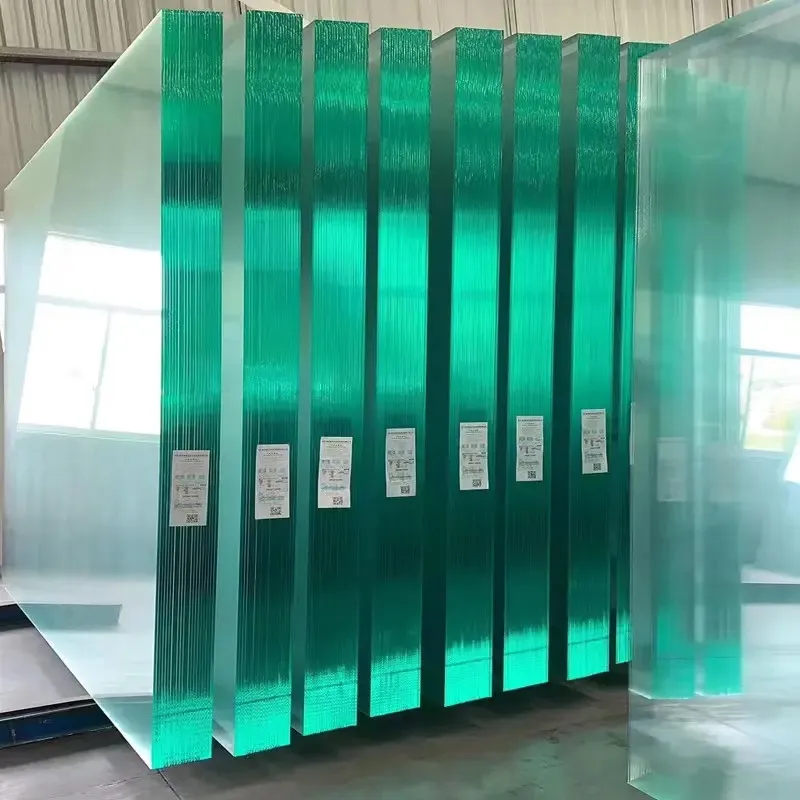

The realm of float glass manufacturing combines precision, innovation, and expertise, contributing significantly to various industries with its versatile applications. Renowned for its seamless finish and clarity,

float glass emerges as a product of meticulous engineering, evident in each phase of its manufacturing process.

In the initial phase, raw materials such as silica sand, soda ash, and limestone undergo careful selection, scrutinized for purity and quality. Their precise composition plays a vital role in the integrity of the final product. Expert formulations ensure that the resulting glass possesses the desired attributes necessary for its wide-ranging applications from construction to automotive industries.

Within the manufacturing plant, these raw materials are meticulously measured and blended, forming a uniform mixture. Subsequently, this mixture undergoes thermal treatment in a furnace, reaching temperatures upwards of 1700°C. At this juncture, industry expertise dictates the careful management of the furnace conditions to achieve the required viscosity and homogeneity within the molten glass.

A hallmark of float glass manufacturing is the float bath, orchestrating a continuous ribbon of glass floating on a bed of molten tin. This process, requiring acute attention to detail, produces glass with perfectly even surfaces and uniform thickness. The controlled atmospheric conditions within this stage are crucial, preventing any chemical interactions that might compromise the glass quality. This unique aspect of production is why float glass is renowned for its optical clarity and unblemished surface.

float glass manufacturing

Following the formation phase, the glass undergoes a robust annealing process in a controlled cool-down atmosphere, ensuring the release of internal stresses. Expertise in managing this phase is critical, as inadequate annealing could lead to susceptibility to stress fractures. Precision engineering continues to guide the process, providing necessary refinements that ensure the glass meets stringent industry standards.

The culmination of the float glass manufacturing process is intensive quality inspection and testing. Professionals in this domain employ both automated systems and expert evaluation to verify clarity, consistency, and physical dimensions, achieving compliance with international standards.

Beyond production, the lifecycle of float glass includes considerations for sustainability and environmental impact. Forward-thinking manufacturers engage in practices aimed at reducing their ecological footprint, emphasizing recycling and energy-efficient operational improvements. These efforts bolster reputations, fostering trust and credibility within the industry and among consumers.

In conclusion, the production of float glass embodies a blend of experience, technological precision, and environmental consciousness. Each facet of the manufacturing process reflects a deep-seated knowledge of glass chemistry and physics, aligning with the highest standards of excellence. Producing float glass not only fulfills commercial needs but also stands as a testament to human ingenuity in material science, providing a durable, high-quality product essential to modern infrastructure and daily life.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu