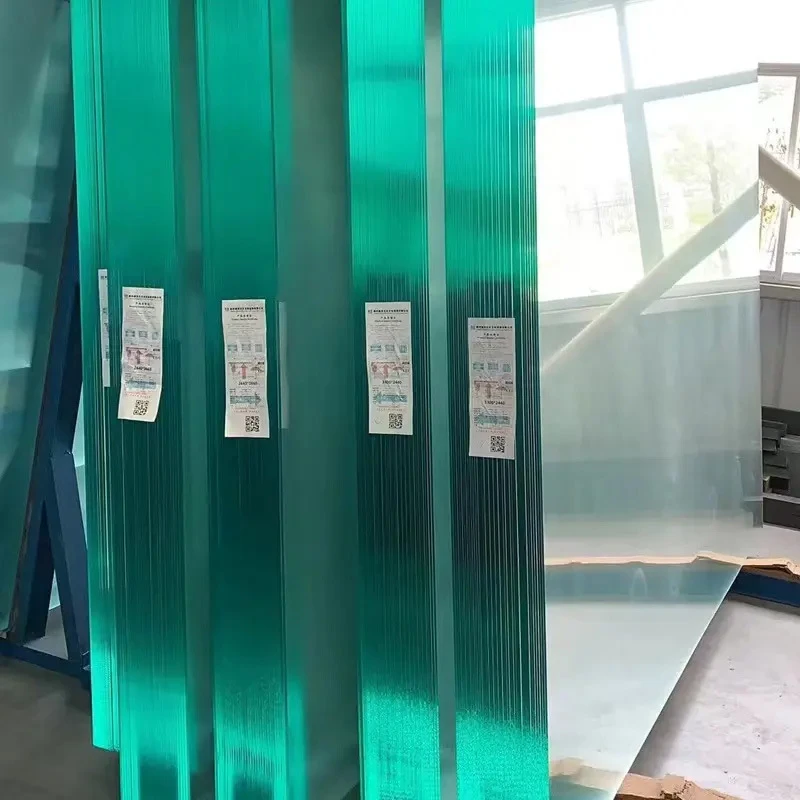

When designing architectural marvels or creating distinctive interior designs, choosing the right type of glass can be crucial. Among various options, 10mm float glass stands out as a versatile and reliable material. Its significance lies not only in its basic structure but also in its exceptional properties and diverse applications.

Float glass production is a fascinating process that begins with raw materials such as silica, soda ash, and lime. These substances are melted at high temperatures in a furnace and then floated over molten tin to ensure a flat and uniform surface.

The result? A flawless glass with perfectly parallel surfaces.

The unique properties of 10mm float glass make it the material of choice for several industries. Its robustness is perhaps its most compelling feature—providing substantial resistance to impact, while maintaining a sleek, modern aesthetic. This balance between strength and beauty is perfect for spaces that require durability without compromising on design.

Architects and builders cherish 10mm float glass for its transparency and visual appeal, allowing seamless integration into structures where natural light is a priority. When utilized as windows in residential or commercial buildings, it maximizes sunlight, which not only reduces the need for artificial lighting but also promotes a healthier indoor environment.

In addition to its aesthetic applications, 10mm float glass serves practical purposes. It's frequently deployed in constructing exteriors, such as curtain walls and façade skylights, offering both functionality and contemporary charm. Its thickness provides excellent insulation properties, which contribute to energy efficiency—a critical consideration in modern design.

10mm float glass

10mm float glass exhibits an impressive degree of customization, allowing designers to tailor it to specific project needs. Whether it's beveling, etching, or tinting, this glass can be modified to suit aesthetic preferences and functional requirements. Its adaptability has led to innovative uses in furniture, interior partitions, and balustrades, significantly enhancing interior spaces with its versatility.

Furthermore, 10mm float glass meets high safety standards. It can be tempered to increase its strength dramatically while maintaining its lightweight form. In the unfortunate event of breakage, tempered glass shatters into small, blunt pieces, reducing the risk of injury—an essential feature for buildings that prioritize safety and security.

When experts discuss the environmentally friendly nature of building materials, 10mm float glass often emerges as a favorable option. It’s durable, long-lasting, and recyclable. Its production involves processes that continually evolve to become more eco-efficient, aligning with global sustainability goals. Architects and designers who are conscious of their environmental impact frequently turn to float glass as a sustainable building solution.

Trusting 10mm float glass means leaning on decades of material science and manufacturing innovations. It’s a choice backed by expertise and authoritative industry voices, ensuring its place at the forefront of construction and design. This reliability underscores its widespread use and the trust professionals place in its performance and adaptability.

In conclusion, the strategic selection and application of 10mm float glass can redefine spaces, offering a blend of elegance, safety, and efficiency. Its ability to harmonize with both modern and classic elements make it an indispensable part of contemporary architecture and design. Whether enhancing visual transparency or providing necessary strength, 10mm float glass remains a testament to the advancement and versatility of human engineering and design ingenuity.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu