The float process, a revolutionary method of glass manufacturing, significantly transformed the industry by offering enhanced quality and consistency. Developed in the 1950s, this method remains a cornerstone of modern glass production. Its impact on product availability and quality has been unmatched, providing a highly efficient and reliable means to produce glass at scale.

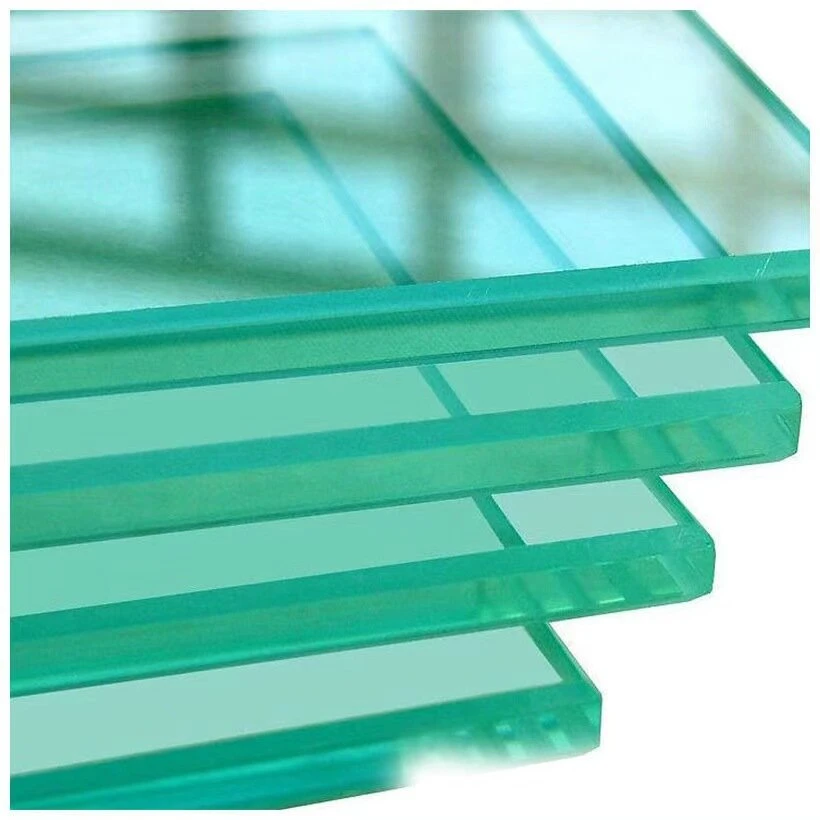

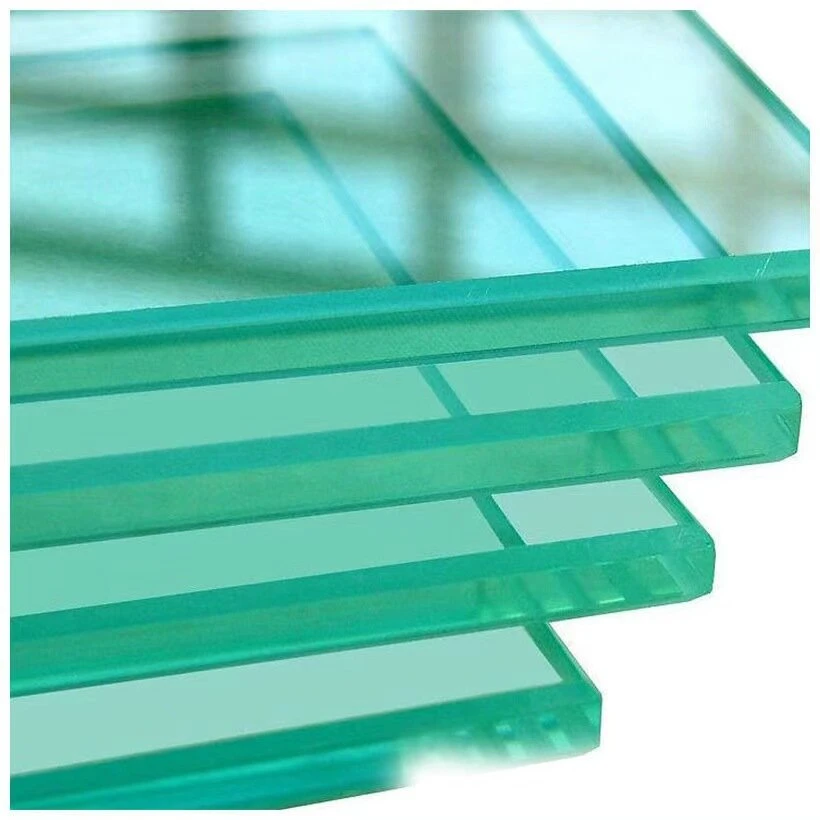

Through this method, molten glass is poured onto a bed of molten tin, allowing it to spread and form a perfect flat sheet.

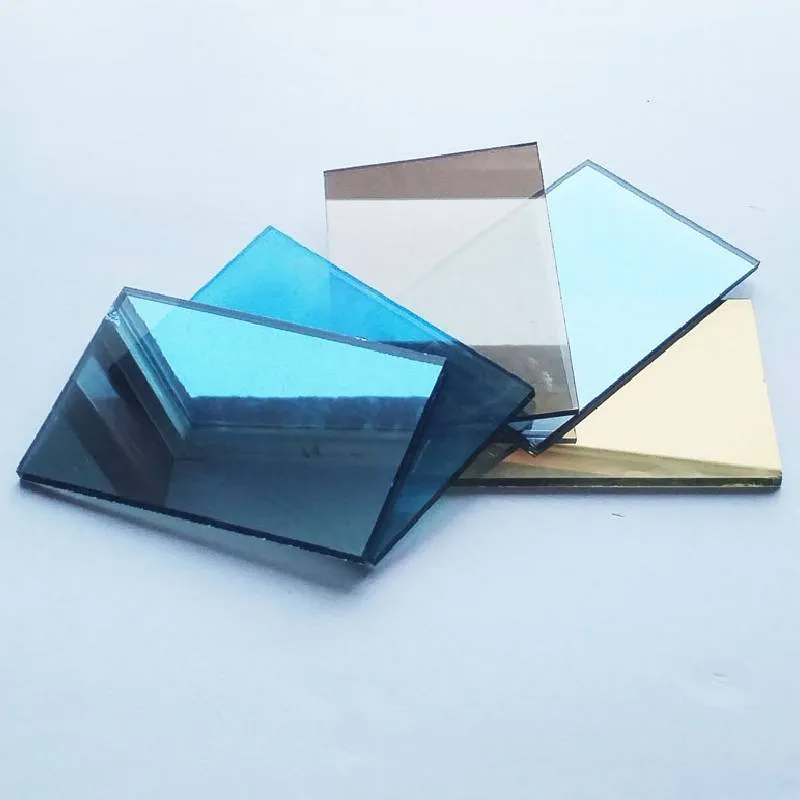

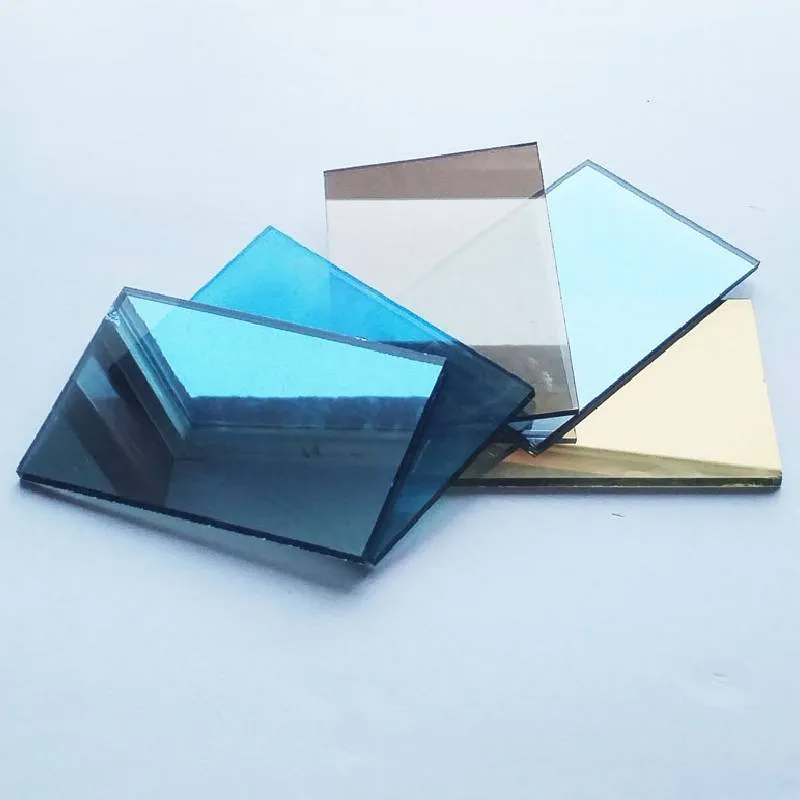

As the molten glass floats on the tin, it cools gradually, resulting in a perfectly smooth surface free of distortions. This precision in manufacturing delivers highly uniform glass, making it the method of choice for producing glass used in a wide variety of applications, from architectural to automotive industries.

The float process is noted for its technical expertise and authority. Engineers and industry professionals rely on this method for producing glass that meets rigorous safety and quality standards. Its engineering brilliance lies in maintaining a carefully controlled environment, where the temperature of both glass and tin is meticulously managed to ensure optimal results. Expertise in chemical properties and thermal dynamics is critical, as slight variations in temperature or composition can affect the outcome.

Trust in the float process is built upon decades of successful applications. Industry veterans have seen how the method leads to reduced material waste and increased production efficiency. Companies providing float glass have demonstrated a strong commitment to innovation and quality assurance, solidifying their reputation as leaders in the field. Partnerships with research institutions have further enhanced understanding and potential improvements, underpinning the process's status as trusted and authoritative.

float process

For products, the float process ensures an unmatched level of clarity and strength. Its precision manufacturing leads to high-quality glass that is less prone to deformities, which is crucial for safety and aesthetic reasons. Architectural designs benefit greatly from its optical clarity, enabling expansive glass structures with minimal visual distortion. In the automotive industry, the robust nature of float glass means greater safety and durability.

The float process’s sustainability aspects add another feather to its cap, aligning with modern ecological directives without compromising on quality or efficiency. Recycled glass can be incorporated, reducing raw material consumption and energy usage. The commitment to sustainability enhances the trustworthiness of the float process, confirming its relevance in today's environmentally-conscious market.

In summary, the float process stands as a testament to human ingenuity within the glass manufacturing industry. Its ability to produce high-quality, uniform glass has made it an indispensable tool for industries worldwide. Backed by extensive technical expertise and years of reliable application, the float process will continue to be a benchmark of excellence in glass production, ensuring trust and authority in its results for years to come.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu