Float glass, a pivotal innovation in the world of architectural design and manufacturing, offers a variety of types catering to diverse needs. This robust, clear, and uniformly thick glass epitomizes the blend of tradition and technology. It is manufactured by floating molten glass on a bed of molten tin, which creates a perfect balance of smoothness and clarity across its surface. Navigating through the different types of float glass unveils a realm of possibilities for construction and design industries, each possessing unique attributes tailored for specific applications.

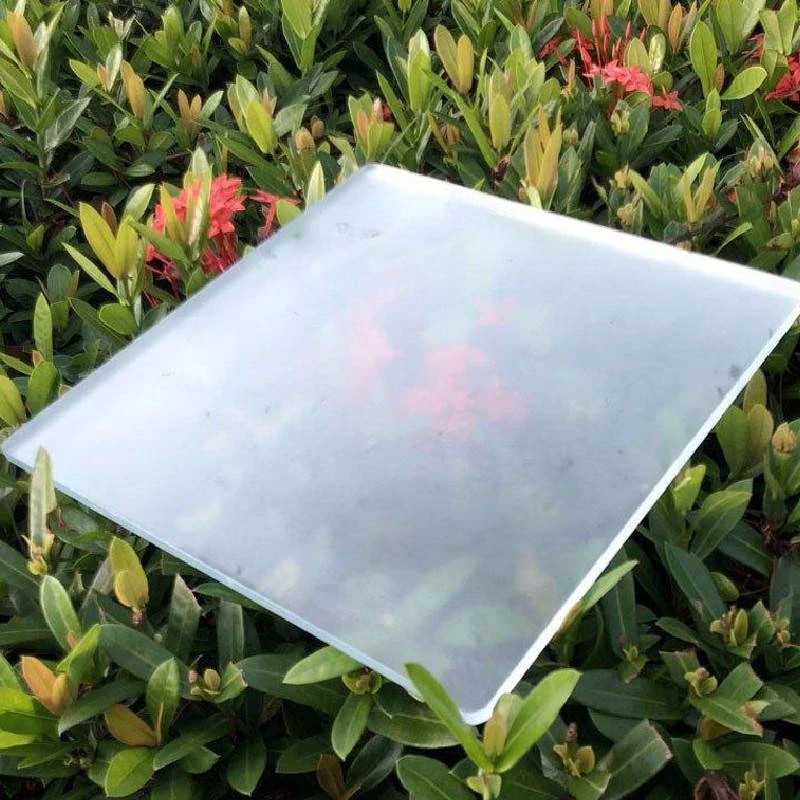

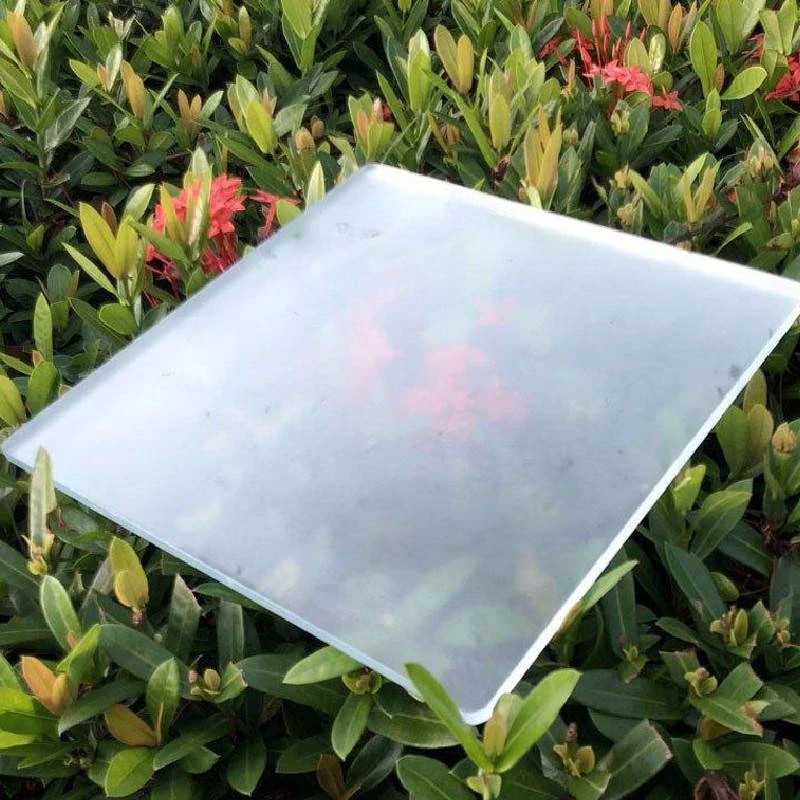

Clear float glass is perhaps the most ubiquitous type, celebrated for its versatility and simplicity. This glass type serves as the foundation for many architectural and decorative glass applications. It allows optimal light transmission, making it suitable for windows, doors, and facades. Its clarity and transparency also make it an ideal canvas for further processing, such as tinting and mirroring, transforming it into a multi-utility product that can meet both aesthetic and functional requirements.

Tinted float glass, infused with colorants during its production, provides aesthetic enhancement and functional benefits. By reducing glare and controlling the ingress of solar radiation, this glass variant contributes to interior comfort and energy efficiency. Depending on the level of tint, it can absorb up to forty to fifty percent of solar energy, making it a preferred choice for projects where temperature regulation and aesthetic cohesion are crucial. Architects and designers leverage its subtle color variations to create visually striking buildings that reflect the personality of a structure.

Reflective float glass takes functionality a step further by incorporating a metallic coating on one side of the glass. This feature reflects a significant portion of sunlight, minimizing heat gain during sunny days while maintaining interior illumination through natural light. The reflective glass is highly regarded for its ability to enhance privacy by reducing visibility from the outside, while simultaneously giving a modern, sleek look to contemporary buildings. Its use is prevalent in high-rise structures and commercial edifices aiming to reduce HVAC costs and bolster environmental sustainability goals.

types of float glass

Laminated float glass underscores safety and security. This version consists of two or more sheets of glass bonded together with layers of plastic, usually polyvinyl butyral (PVB). Its design ensures that, upon impact, the glass adheres to the interlayer, minimizing the risk of injury from sharp shards. Laminated glass is widely used in applications where safety is paramount, such as automotive windshields, skylights, and sound insulation barriers. Its safety benefits are complemented with sound reduction qualities, making it invaluable in noise-sensitive environments.

Lastly, low-emissivity (Low-E) float glass represents an evolution in energy-efficient building materials. Coated with microscopically thin, transparent layers of silver or other metal oxide, Low-E glass reflects thermal radiation while allowing visible light in. This capability significantly reduces energy costs by retaining heat inside buildings during colder months and reflecting the sun’s heat rays during warmer periods. Its integration in architectural design is seen as an embodiment of innovation, offering eco-friendly solutions without compromising on aesthetic qualities.

Each type of float glass presents a unique blend of performance characteristics tailored for specific needs, underscoring the importance of selecting the appropriate glass type to suit the demands of any project. Combining technical expertise with strategic product selection ensures that float glass continues to play an indispensable role in modern architecture and manufacturing. From energy efficiency to enhanced aesthetics and safety, the varied applications of float glass underscore its paramount importance in the pursuit of sustainable and innovative building solutions.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu