Finding the right float glass manufacturer for your needs involves understanding not just the product specifications but also the expertise and trustworthiness of the manufacturer. Float glass, a predominant window material known for its smooth, distortion-free surface, is essential for various architectural and automotive applications. Ensuring that your supplier exhibits the best qualities in manufacturing and customer service is vital.

When selecting a float glass manufacturer, prioritize their experience. Manufacturers with decades of experience in the industry bring invaluable expertise that ensures they have honed their production processes to meet high-quality standards. Established manufacturers also bring a proven track record of reliability, which is essential in maintaining supply chain consistency.

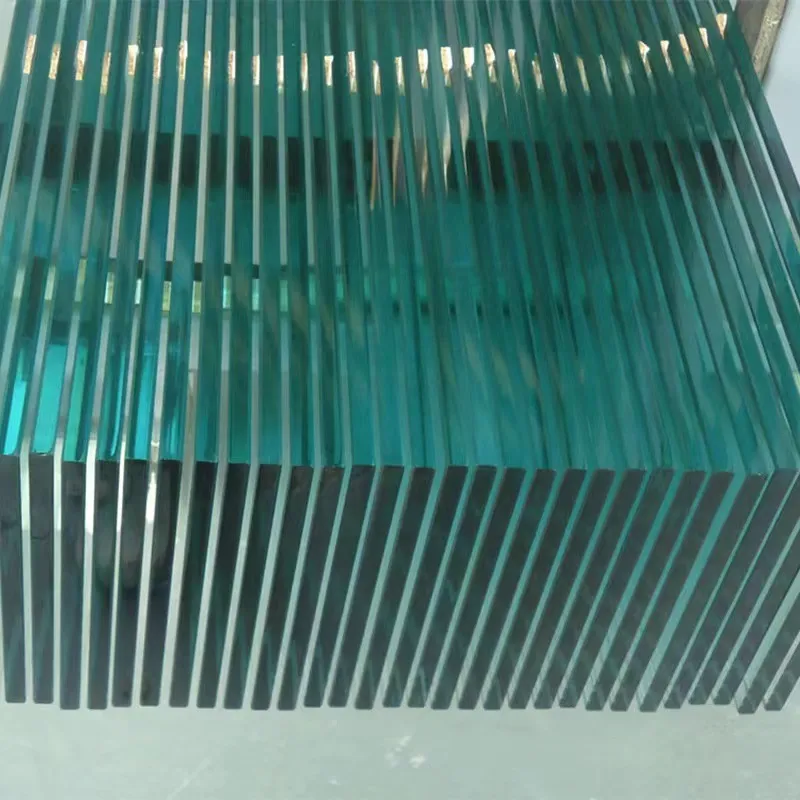

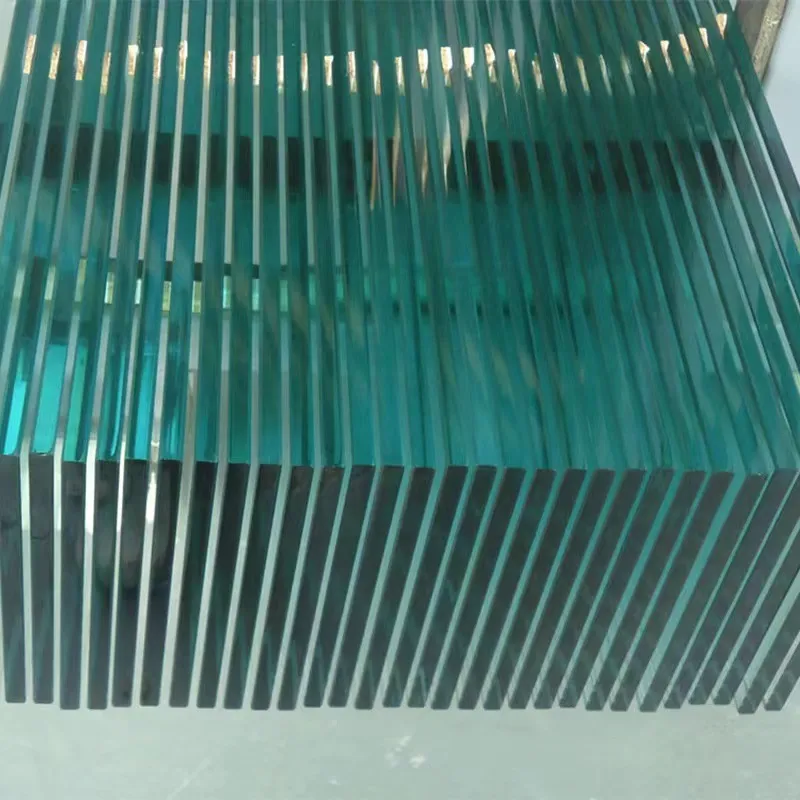

Expertise in float glass manufacturing is indicated by a manufacturer's comprehensive understanding of the production process. The float glass manufacturing process involves floating molten glass on a bed of molten metal to produce a uniform thickness and flat surface. Expert manufacturers invest in state-of-the-art technological advancements to enhance production efficiency and product quality. Look for manufacturers who prioritize research and development, continuously improving their processes and materials to offer superior products. These manufacturers are often involved in industry collaborations and associations, further showcasing their commitment to quality and innovation.

Authoritativeness in this field is reflected in the certifications and accolades a manufacturer has received. Reputable glass manufacturers comply with international standards such as ISO certifications, demonstrating their adherence to quality and safety protocols. Additionally, awards and recognitions from industry bodies can enhance a manufacturer's credibility, indicating their status as a leader in float glass production. Consider choosing manufacturers who are not only recognized within their local market but also on an international scale.

float glass manufacturer

Trustworthiness is critical when building a business relationship with a float glass manufacturer. Transparent communication about their production capabilities, lead times, and pricing is essential. Trust is solidified when a manufacturer provides clear documentation, including technical specifications and test results that support their product claims. Engaging with manufacturers who embrace sustainability in their operations can also be a testament to their trustworthy practices, as they show a commitment to environmental responsibility.

Another aspect to consider is the manufacturer's customer service. A manufacturer that goes beyond merely supplying products stands out in the industry. Consider manufacturers who offer value-added services such as technical support, training, and after-sales services. The ability to partner with a manufacturer that understands your specific project requirements and provides tailored solutions can be a game-changer in maximizing the efficiency and success of your projects.

By emphasizing experience, expertise, authoritativeness, and trustworthiness, you ensure that your choice of float glass manufacturer aligns with your business goals and upholds industry standards. The right manufacturer doesn't just meet your immediate needs but becomes a reliable partner in your long-term success. In an industry where precision and quality are paramount, aligning with a manufacturer who shares your values and vision ensures the excellence and dependability of your final products.

In conclusion, selecting a float glass manufacturer is a decision that affects the quality of your products and your business's overall success. Carefully evaluating potential manufacturers against these four key indicators will lead to more informed choices, setting the foundation for a thriving and hassle-free business relationship.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu