The Cost of Toughened Glass A Comprehensive Overview

Toughened glass, also known as tempered glass, is a type of safety glass that has been treated by controlled thermal or chemical processes to increase its strength compared to normal glass. This enhancement makes toughened glass an ideal choice for various applications, from facades and windows to shower doors and tabletops. However, one of the primary considerations when deciding whether to use toughened glass in a project is its cost. This article delves into the factors influencing the cost of 10mm toughened glass, shedding light on its pricing dynamics.

Understanding Toughened Glass

Before discussing cost, it’s essential to understand what toughened glass is and why it is favored in construction and design. The toughening process involves heating the glass to over 600 degrees Celsius and then cooling it rapidly. This treatment creates a balance between internal and external stresses in the glass, significantly enhancing its strength. For instance, toughened glass is approximately five to six times stronger than standard glass of the same thickness, making it less likely to shatter under impact.

Cost Factors of 10mm Toughened Glass

When evaluating the price of 10mm toughened glass, several factors come into play, including manufacturing processes, material quality, and additional treatment options.

1. Manufacturing Process The production of toughened glass is more complex than that of standard glass. This complexity leads to higher production costs. The glass must be heated and cooled in specialized ovens, which require significant energy and controlled environments. These manufacturing expenses directly influence the final price.

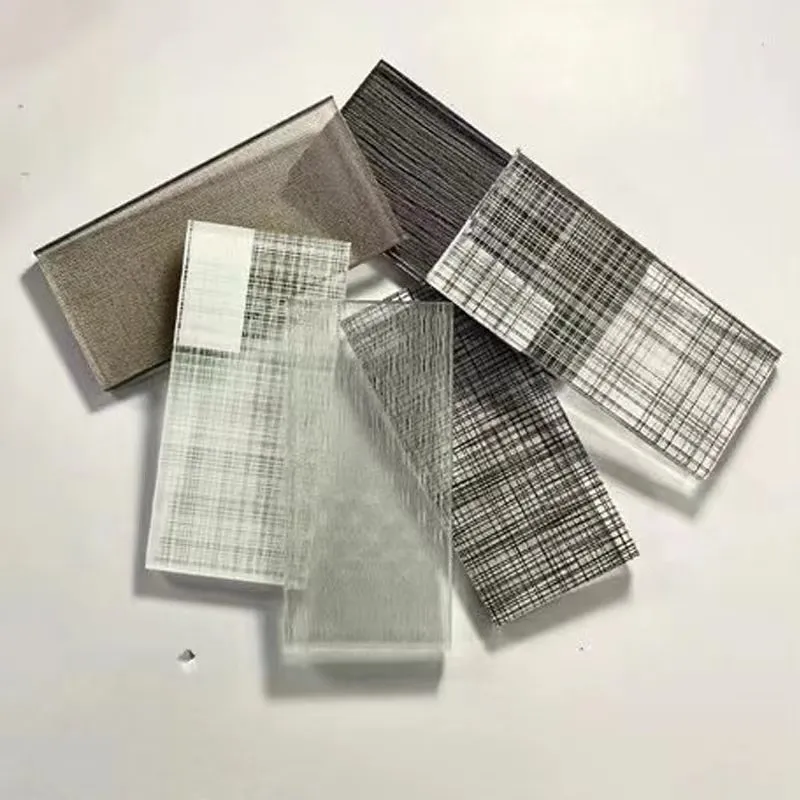

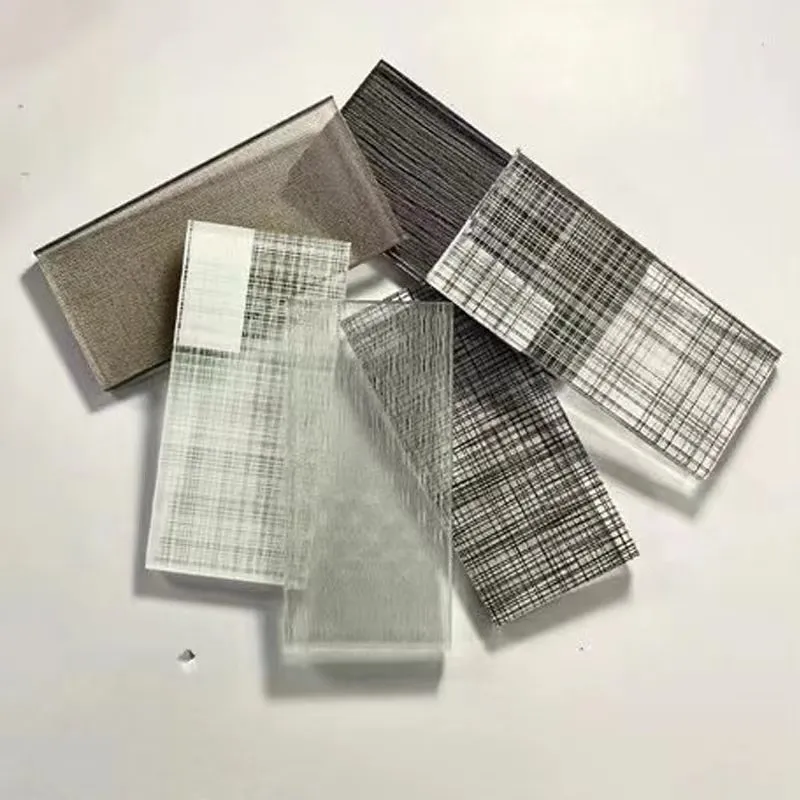

cost of toughened glass 10mm

2. Material Quality The type of raw materials used also affects the cost. High-quality silica sand and other raw materials that meet specific standards tend to be more expensive. The purity of these materials not only impacts the price but also the performance characteristics of the final product, such as clarity and resistance to corrosion.

3. Size and Thickness Thickness plays a significant role in determining price. While 10mm toughened glass is a standard thickness used in many applications, larger pieces or custom shapes can drive prices higher due to the increased handling and processing requirements.

4. Treatment and Finishing Additional treatments, such as coating or etching, can also add to the cost. These options enhance performance, improve aesthetics, or provide UV protection, but they do come at a price. For example, low-emissivity (Low-E) coatings can increase the thermal efficiency of glass, yet their application leads to an increase in overall costs.

5. Market Demand and Supply Like any other commodity, the pricing of toughened glass is also influenced by market dynamics. Increased demand in construction, architecture, and home improvement can drive prices upwards. Likewise, fluctuations in the availability of raw materials can impact costs.

Conclusion

In summary, while the cost of 10mm toughened glass may be higher than standard glass, its enhanced safety features and durability justify the investment in many scenarios. Understanding the various factors that influence its pricing can help consumers and professionals make informed decisions when selecting materials for their projects. Whether for a commercial building façade or a stylish shower enclosure, the cost of toughened glass reflects its quality, manufacturing processes, and the value it brings to safety and design. In a world prioritizing both aesthetics and security, toughened glass stands out as a worthy choice.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu