The Flat Glass Manufacturing Industry An Overview

Flat glass manufacturing is an essential sector within the broader glass industry, producing a variety of glass products that are integral to modern architecture and a multitude of everyday applications. This article will delve into the processes, materials, and significance of flat glass manufacturing.

Manufacturing Processes

Flat glass is typically produced through two primary methods the float glass process and the rolled glass process.

1. Float Glass Process This method, invented in the 1950s, dominates the flat glass industry. It involves melting silica sand, soda ash, and limestone into a viscous liquid at high temperatures. The molten glass is then poured onto a bed of molten tin. The glass floats on the tin, resulting in a perfectly flat and smooth surface as it cools. This process enables the production of large sheets of glass with uniform thickness, which can then be cut into various sizes for windows, mirrors, and other applications. The float method is prized for its clarity and absence of distortions.

2. Rolled Glass Process This older method involves rolling molten glass into a flat sheet using rollers. While it allows for the production of textured glass, rolled glass is less common than float glass due to its limitations in producing large, clear sheets. It is often used for decorative purposes or in applications where distortion is not a critical factor.

Key Materials

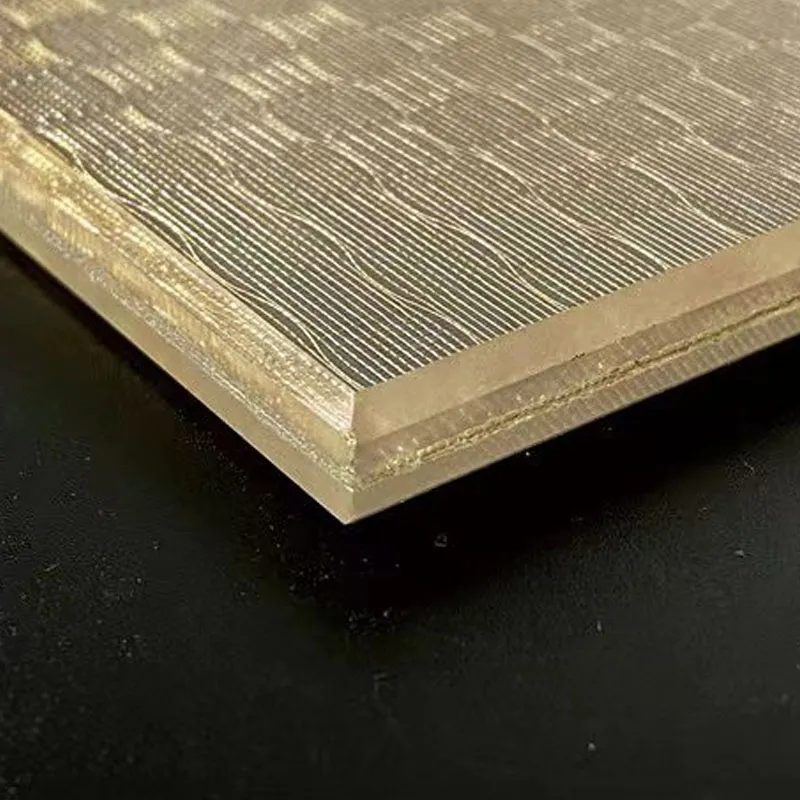

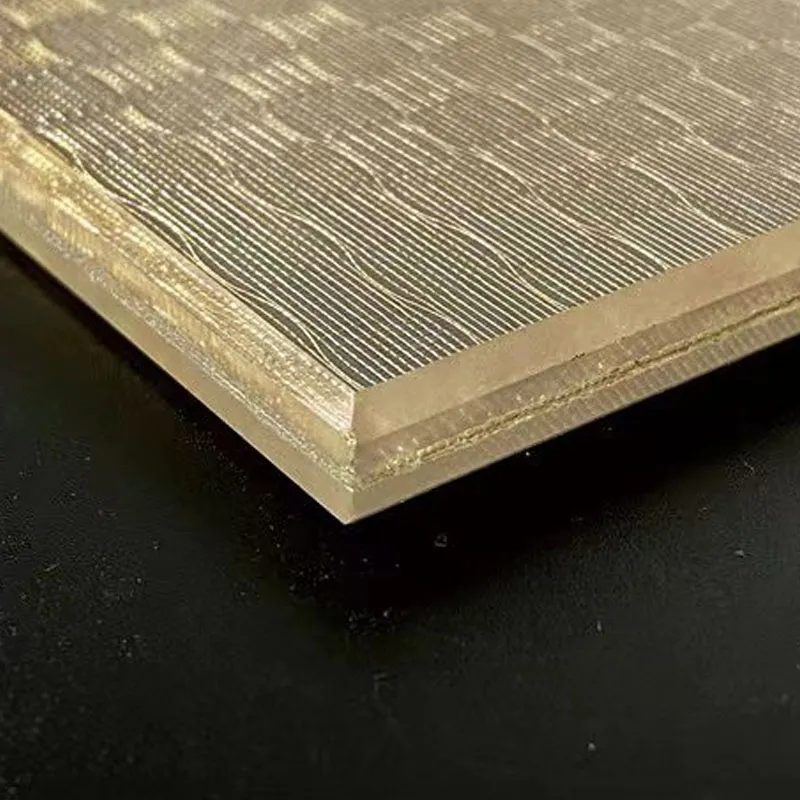

flat glass manufacturing

The primary raw materials involved in flat glass manufacturing include silica sand, soda ash, limestone, and various chemicals that enhance properties like strength and UV resistance. The choice of materials greatly influences the glass's characteristics, including thermal efficiency, clarity, and durability. Innovations in materials, such as the incorporation of recycled glass, play a crucial role in improving sustainability within the industry.

Environmental Considerations

The flat glass manufacturing sector has made significant strides in sustainability. The production process is energy-intensive, but advancements in technology have improved energy efficiency. Many manufacturers are adopting practices like recycling waste glass, also known as cullet, which reduces the need for raw materials and energy. This not only lowers manufacturing costs but also minimizes environmental impact.

Additionally, the rise of energy-efficient buildings has driven demand for specialized flat glass products, such as low-emissivity (Low-E) glass, which reflects infrared radiation while allowing visible light to pass through. This technology contributes to energy conservation in buildings by reducing heating and cooling costs.

Market Trends

The flat glass market is experiencing growth due to several factors, including urbanization, increasing construction activities, and a growing focus on renewable energy sources. The rise of solar energy has spurred demand for flat glass in photovoltaic applications, where glass is used to cover solar panels, enhancing both functionality and aesthetics.

In conclusion, the flat glass manufacturing industry plays a critical role in modern society, offering a wide range of products integral to architecture, automotive, and energy sectors. As the industry continues to evolve, it must balance the demands for high-quality products with the need for sustainable practices, ensuring it contributes positively to both the economy and the environment. With ongoing innovations and a commitment to eco-friendly production, the flat glass industry is poised for a bright future.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu