The Timeless Elegance of Flat Glass Mirrors

In today’s world, the flat glass mirror stands as a quintessential element of both functionality and aesthetic appeal in our daily lives. From the smallest handheld mirrors to expansive wall-mounted pieces, these reflective surfaces not only play a vital role in personal grooming but also enhance the ambiance of any space. In this article, we shall explore the historical development, manufacturing processes, applications, and future trends of flat glass mirrors, revealing why they continue to captivate us.

A Historical Perspective

The use of mirrors can be traced back thousands of years, with early civilizations utilizing polished metals such as bronze, silver, and gold to create reflective surfaces. However, it was during the Middle Ages that glass began to emerge as a favored material for mirror-making. By the 16th century, the Venetian artisans of Murano had mastered the craft of glassmaking, producing some of the finest flat glass mirrors of their time. These mirrors, framed in ornate designs, became symbols of wealth and sophistication, adorning the palaces and homes of the elite.

The advancement of technology in the 19th century revolutionized mirror production. With the introduction of amalgamation—coating glass with a thin layer of metallic silver—manufacturers were able to produce mirrors on a larger scale. This innovation made flat glass mirrors more accessible to the general public, transforming them from luxury items into household essentials.

Composition and Manufacturing Process

Flat glass mirrors are typically composed of a sheet of glass that is coated with a reflective layer, usually silver or aluminum. The manufacturing process begins with the production of flat glass, which is crafted by melting silica sand, soda ash, and limestone. Once the glass reaches the desired thickness, it is cooled and then polished to achieve a smooth surface.

Next, the mirror production involves applying a reflective coating. In the case of silvering, a solution of silver nitrate is deposited onto the glass surface, forming a thin, highly reflective layer. Afterward, a protective paint layer is applied to prevent tarnishing and enhance durability.

Quality control is paramount in the manufacturing of flat glass mirrors. Factors such as thickness, clarity, and absence of imperfections are rigorously inspected to ensure the final product meets industry standards.

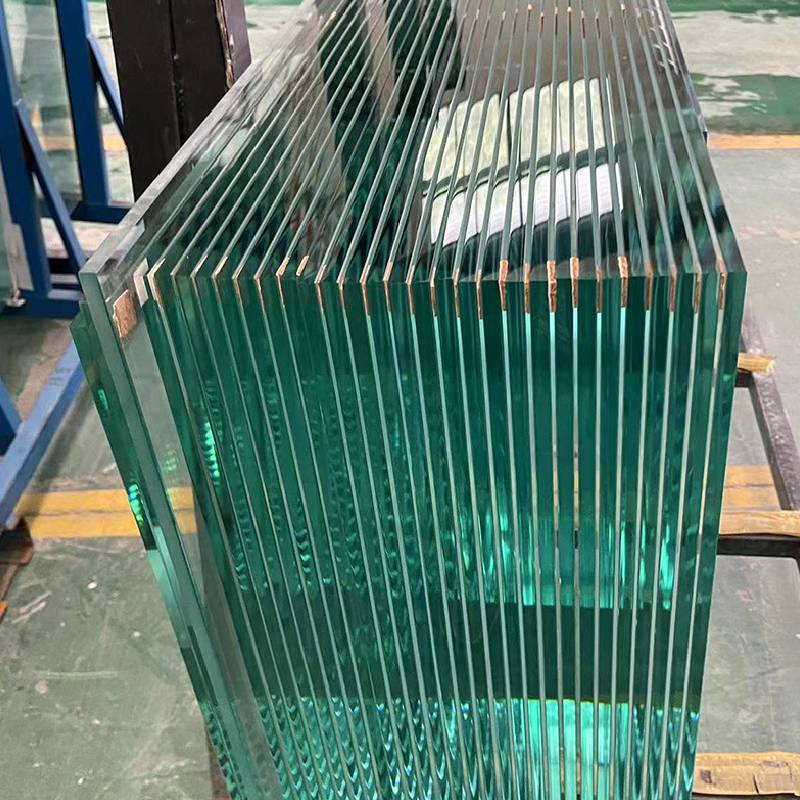

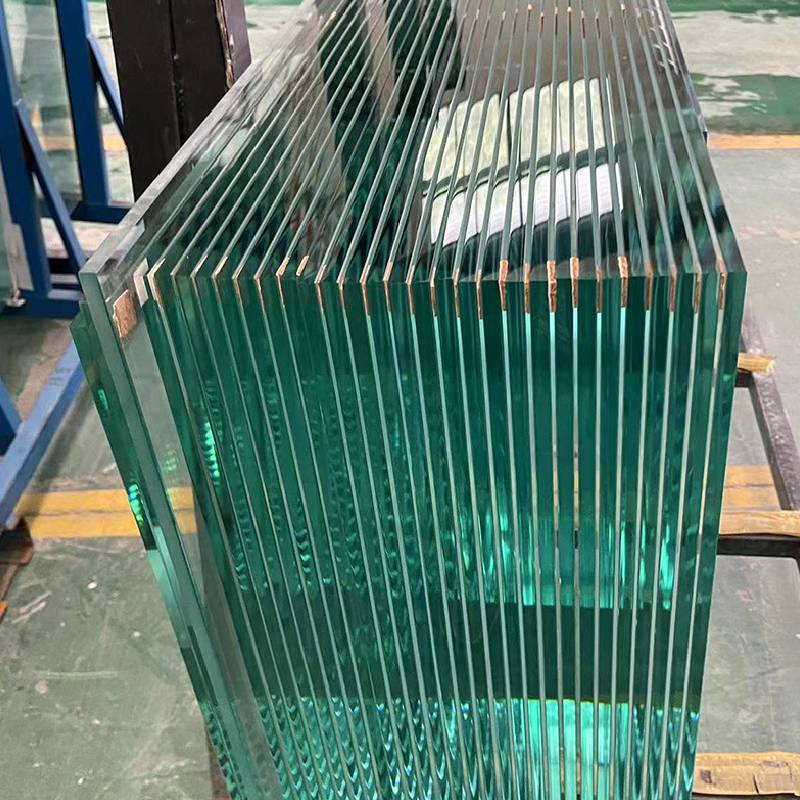

flat glass mirror

Applications in Everyday Life

The versatility of flat glass mirrors allows them to be utilized in various settings. In homes, they serve not only as functional objects for daily grooming but also as decorative elements, capable of making a space feel larger and brighter. Strategically placed mirrors can reflect light and create an illusion of depth, transforming dull or cramped rooms into inviting spaces.

In commercial environments, mirrors play a crucial role in retail and hospitality. They are often employed to enhance the visual appeal of a store, enticing customers to engage with products. Additionally, many restaurants and hotels incorporate mirrors into their designs, creating an atmosphere of elegance and sophistication.

Beyond residential and commercial uses, flat glass mirrors are also significant in architecture and design. Architects often integrate mirrors into their projects to create striking visual effects and to manipulate space in innovative ways. Furthermore, mirrors are widely used in scientific applications, such as telescopes and lasers, where precision reflection is critical.

The Future of Flat Glass Mirrors

As technology continues to evolve, so too does the flat glass mirror. Innovations in smart mirror technology, for instance, are leading to interactive surfaces capable of displaying information, such as time, weather forecasts, and personal notifications. These smart mirrors represent a fusion of functionality and modern aesthetic, appealing to a tech-savvy audience.

Sustainability is another trend impacting the future of flat glass mirrors. Manufacturers are increasingly focusing on eco-friendly production processes, utilizing recycled materials, and developing energy-efficient coatings. As environmental concerns become more pressing, the demand for sustainable products is likely to grow.

Conclusion

Flat glass mirrors are more than just reflective surfaces; they embody a rich history, a blend of artistry and science, and a reflection of our daily lives. As we embrace technological advancements and sustainable practices, these mirrors will undoubtedly continue to enchant and inspire future generations, affirming their place as timeless accessories in our homes and beyond.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu