The Flat Glass Process A Comprehensive Overview

The flat glass process is a critical method employed in the production of glass sheets that are widely used in various industries, including construction, automotive, and electronics. This process involves several stages, each crucial in ensuring the quality and efficiency of the final product.

The journey of flat glass begins with the raw materials, primarily silica sand, soda ash, and limestone. These ingredients are carefully measured and mixed to create a batch. The precise composition is vital as it determines the glass's properties, such as clarity, strength, and thermal resistance. Once the batch is prepared, it is fed into a furnace where it is heated to temperatures exceeding 1,600 degrees Celsius. This high heat transforms the raw materials into molten glass.

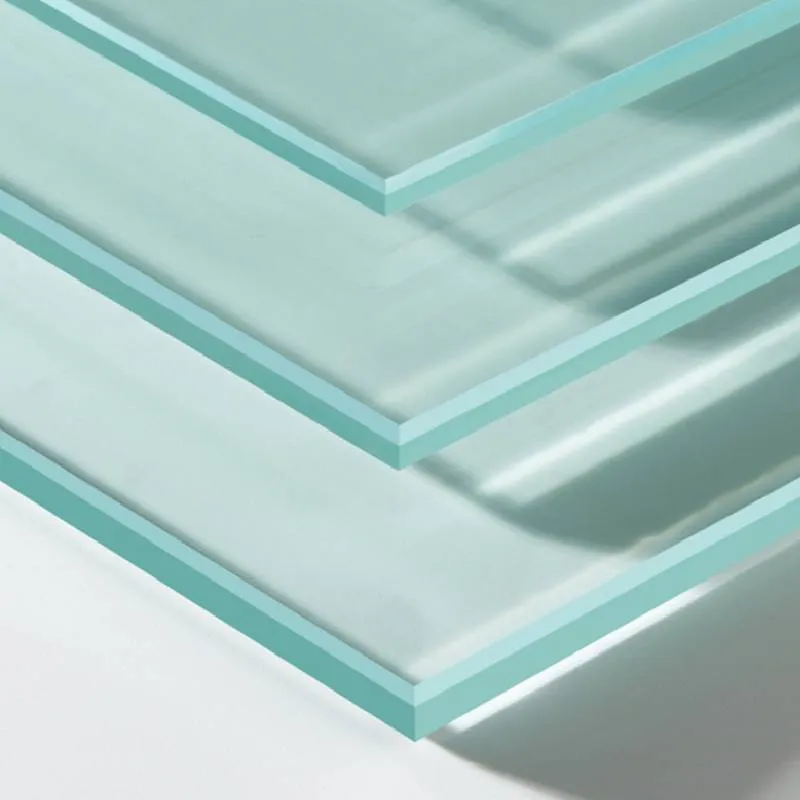

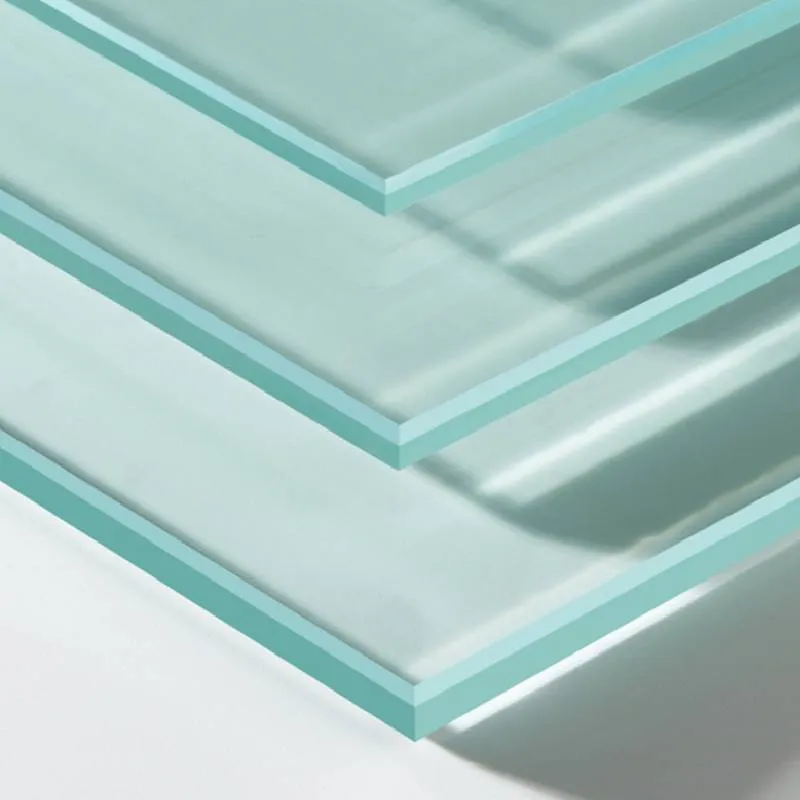

The next step in the flat glass process is forming the molten glass into flat sheets. This is typically achieved through two main techniques the float glass process and the cast glass process. The float glass process, developed in the mid-20th century, is the most common method used today. In this process, the molten glass is poured onto a bed of molten tin. The lighter glass floats on the tin and spreads out, forming a smooth and flat sheet due to gravity and surface tension. This results in glass sheets with uniform thickness and excellent optical clarity.

The cast glass process, on the other hand, involves pouring molten glass into molds to create thicker glass sheets and specialized shapes. While this method is not as widely used for mass production, it is still essential for creating unique glass products, such as artistic items and custom architectural features.

flat glass process

After the glass is formed, it undergoes a series of cooling processes, which are critical in reducing internal stresses that may lead to breakage. This cooling occurs in a controlled environment known as the lehr, where the temperature is gradually decreased. The lehr ensures that the glass maintains its structural integrity and achieves the desired properties.

Once cooled, the glass is inspected for quality. A rigorous quality control system is in place to check for defects such as bubbles, scratches, and distortions. Any sheets that do not meet the established standards are removed from the production line to ensure that only high-quality glass reaches the market.

The flat glass process does not end with the production of glass sheets. Post-processing is also an essential aspect of the industry. The glass can undergo various treatments, including annealing, tempering, and lamination, depending on its intended application. Tempered glass, for example, is treated with heat or chemicals to enhance its strength and safety, making it a popular choice for automotive and architectural uses.

The versatility and durability of flat glass make it an indispensable material in modern society. From large windows in skyscrapers to touchscreens in smartphones, the applications of flat glass are vast and continually expanding. As technology advances, so does the flat glass process, incorporating innovative techniques and sustainable practices that reduce energy consumption and environmental impact.

In conclusion, the flat glass process is a sophisticated blend of science, engineering, and artistry. It reflects human ingenuity and the desire to create materials that enhance our everyday lives while pushing the boundaries of what glass can achieve in various applications. The future of flat glass production looks promising, rooted in tradition yet driven by innovation.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu