The Flat Glass Production Process An Overview

Flat glass, known for its extensive use in windows, mirrors, and various architectural applications, undergoes a complex production process. This process is essential in creating the high-quality glass products that meet the demands of both manufacturers and consumers. The journey of flat glass production involves several key stages, including raw material preparation, melting, forming, annealing, and finishing.

Raw Material Preparation

The production of flat glass begins with the preparation of raw materials. The primary ingredients typically include silica sand, soda ash, and limestone. Silica sand, which comprises a significant portion of the mixture, provides the glass its fundamental structure. Soda ash lowers the melting point of silica, making it easier to process, while limestone strengthens the final product and helps control its chemical stability. In addition to these main components, various additives may be included to enhance specific properties of the glass, such as color and UV resistance.

Melting

Once the raw materials are prepared, they are mixed and fed into a glass melting furnace. The furnace operates at extremely high temperatures, usually around 1,700 degrees Celsius (3,092 degrees Fahrenheit), to melt the mixture into a molten glass state. This environment must be carefully controlled to ensure that the glass melts uniformly and impurities are minimized. The melting phase is crucial, as any inconsistencies in this stage can lead to defects in the final product.

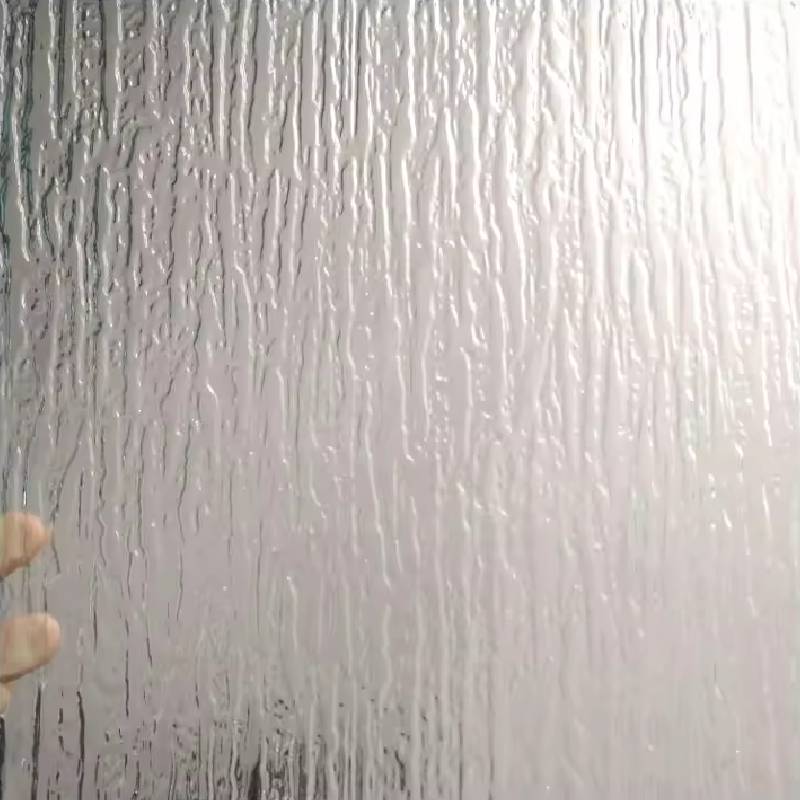

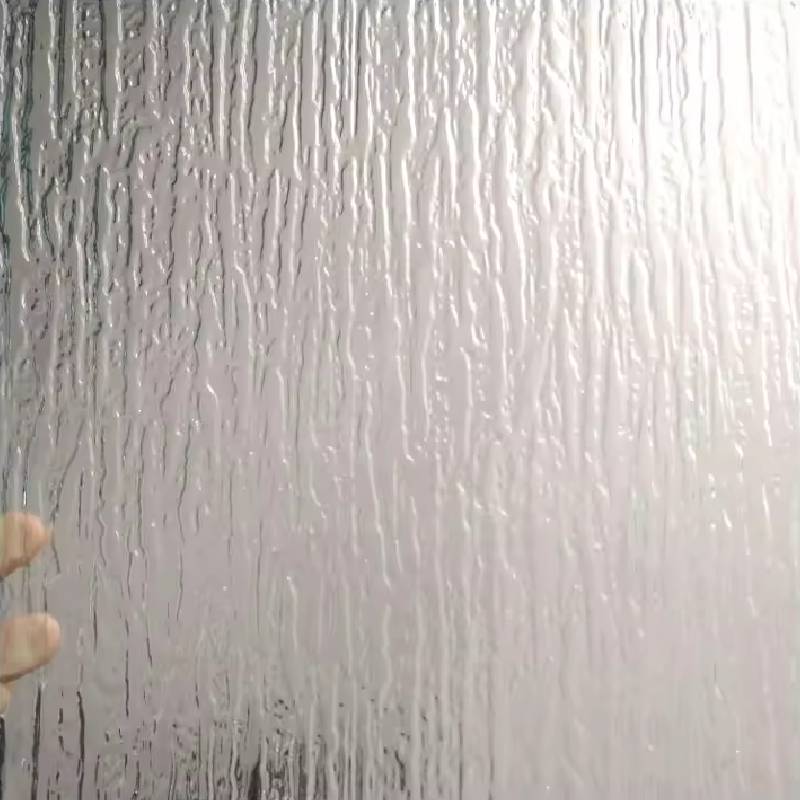

Forming

flat glass production process

After melting, the molten glass is formed into flat sheets using one of several methods, the most common being the float glass process. In this process, the molten glass is poured onto a bath of molten tin, where it naturally spreads out and forms a smooth, flat surface. This method not only creates uniform thickness but also results in a glass surface that is optically clear and free from defects. In some cases, alternative forming techniques such as sheet glass processes may be used, especially for specialty applications.

Annealing

Once formed, the flat glass must be gradually cooled in a controlled environment, known as the annealing lehr. This step is vital to relieve internal stresses introduced during the forming process. Inadequately cooled glass may exhibit flaws, such as breakage or warping, under stress. The annealing process can take several hours and involves precisely controlling the temperature and cooling rate to ensure that the glass retains its integrity and achieves the desired mechanical properties.

Finishing

After annealing, the flat glass moves on to the finishing stage, where it undergoes further treatments to enhance its characteristics. This may include cutting the glass into required sizes, polishing the edges, and applying coatings for added functionality, such as anti-reflective or low-emissivity features. Quality control is a critical aspect of this stage, ensuring that only the best products reach consumers.

In conclusion, the flat glass production process is a sophisticated and multifaceted operation that requires careful attention to detail at every step. From raw material preparation to finishing, each phase plays a pivotal role in producing high-quality flat glass. As demand for energy-efficient and aesthetically pleasing glass products continues to rise, advancements in production techniques are likely to shape the future of this essential industry, ensuring that flat glass remains a vital component in modern architecture and design.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu