The float glass production process is a widely adopted manufacturing method for creating high-quality flat glass, commonly used in windows, mirrors, and other applications. This innovative technique was developed in the mid-20th century and revolutionized the glass industry by enabling the production of large, uniform sheets of glass with superior clarity and strength.

The process begins with the selection and preparation of raw materials. The primary components of float glass are silica sand, soda ash, and limestone, along with various additives to enhance the properties of the final product. These materials are carefully weighed and mixed to create a homogeneous batch. The mixture then undergoes a high-temperature melting process in a furnace, where it reaches temperatures of about 1,700 degrees Celsius, transforming the solid components into a molten glass.

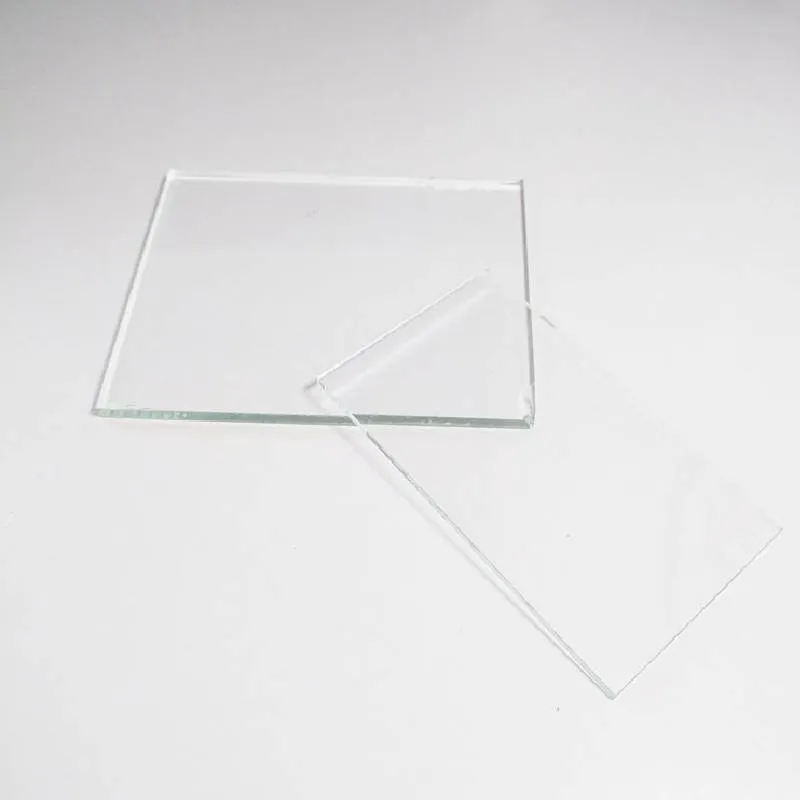

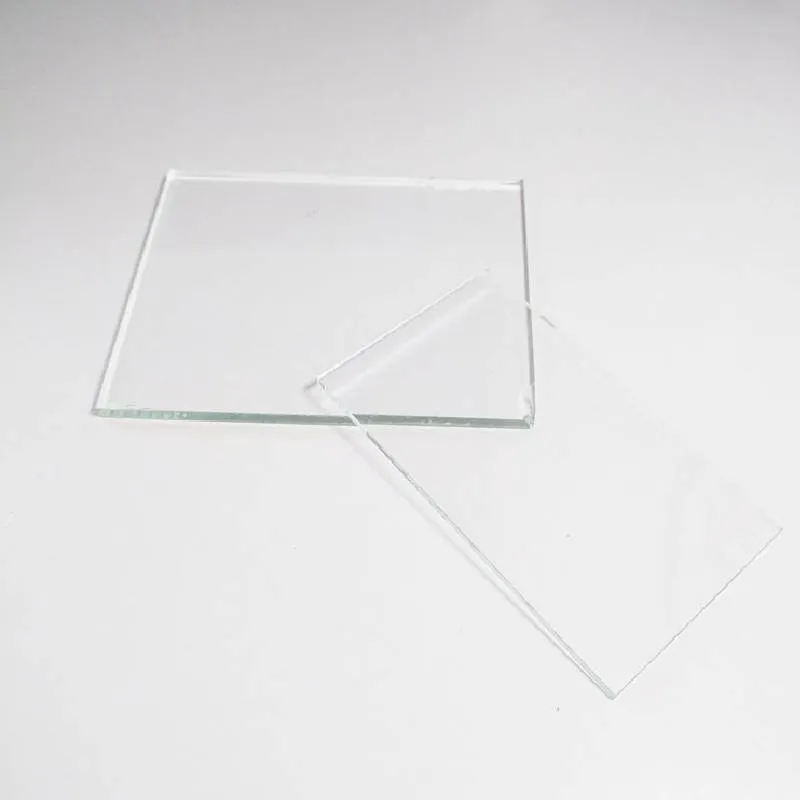

Once the glass is melted, it is poured onto a bed of molten tin in a controlled environment. This is where the float in float glass comes into play. The molten glass floats on the tin surface, allowing it to spread out evenly and form a smooth, flat sheet. The density of the glass and tin is such that the glass maintains a constant thickness during this phase. This unique floating process is crucial, as it results in glass sheets that are remarkably uniform in thickness, typically ranging from 2 to 19 millimeters.

As the glass moves along the float line, it begins to cool down, transitioning from a molten state to a solid form. This cooling process is crucial to prevent internal stresses and distortions. Once the glass has cooled sufficiently, it is cut into the desired dimensions using automated cutting machines. The edges are then polished to ensure safety and aesthetics.

float glass production process

The final stages of the float glass production process involve inspecting and packaging the completed sheets. Quality control is essential throughout the entire process to check for defects, bubbles, and variations in thickness. Only glass that meets stringent quality standards is selected for packaging.

Float glass production not only emphasizes efficiency but also sustainability. Many manufacturers are increasingly utilizing recycled glass in their batches, reducing waste and the overall environmental footprint of the production process.

In conclusion, the float glass production process is a sophisticated method that combines chemistry, engineering, and technology. Its advancements have led to the widespread availability of high-quality glass, contributing significantly to various industries while adhering to modern sustainability practices.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu