Float glass, a pivotal invention in modern architecture and design, plays an indispensable role in our daily lives. To truly appreciate its value, one must delve into its multifaceted utility and production nuances. As an industry expert, my insights are rooted in decades of direct involvement and collaboration with leading glass manufacturers.

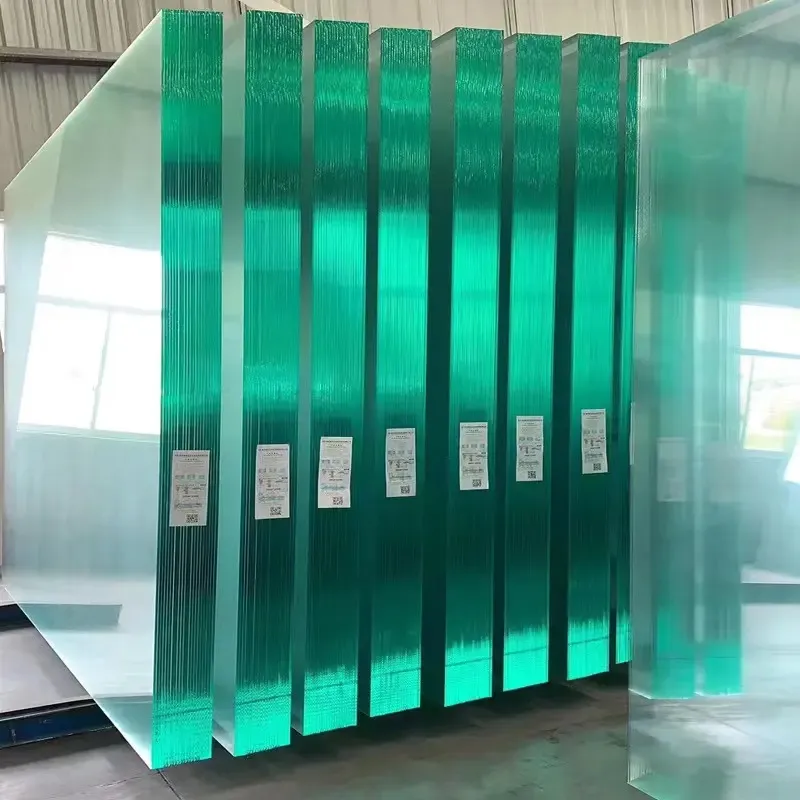

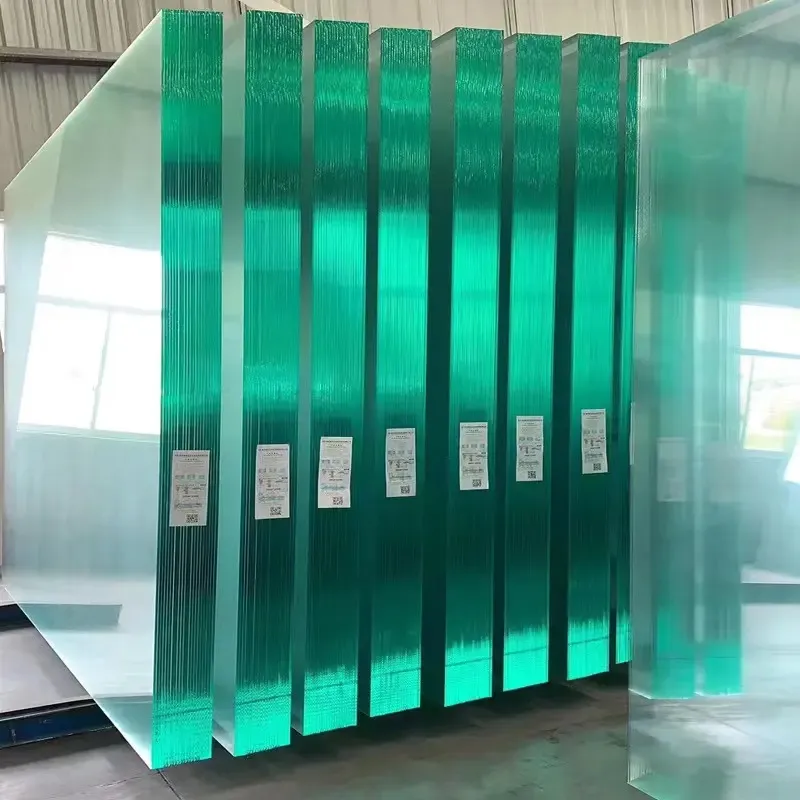

Experience showcases float glass as a revolutionary material, widely celebrated for its flawless finish and optical clarity. Unlike traditional glass-making methods, the float glass process involves floating molten glass on a bed of molten tin. This technique ensures uniform thickness and a perfectly even surface, eliminating the need for polishing or grinding. A tour through a float glass fabrication facility reveals a mesmerizing synergy of precision and innovation, highlighting the meticulous control over temperature and timing that the process demands.

Expertise in the field reveals that float glass isn't merely a product of technological advancement but an essential component with diverse applications. From the sleek facades of skyscrapers to the subtle elegance of residential windows and table tops, float glass provides both aesthetic beauty and functional integrity. Its versatility extends to various forms where it is tempered, laminated, or coated to enhance safety, energy efficiency, and sound insulation. Customizing float glass to meet specific architectural and environmental demands has become a staple practice among industry professionals, reflecting its dynamic adaptation to modern needs.

float glass

Authoritativeness in the domain of float glass is demonstrated by the industry's unwavering commitment to research and development. Renowned institutions and leading manufacturers continuously strive to enhance glass properties, innovating on parameters such as thermal insulation and solar control. The symbiotic partnership between academic research and industrial application has fostered groundbreaking advancements, such as low-emissivity (Low-E) coatings and self-cleaning surfaces. These enhancements not only extend the functional spectrum of float glass but also contribute to sustainable building practices, aligning with global environmental objectives.

Trustworthiness is paramount in float glass production, as the material's reliability is crucial for both structural safety and aesthetic fidelity. Internationally recognized standards and rigorous quality assurance protocols govern the manufacturing process. Industry certifications, such as ISO and EN standards, serve as benchmarks for quality, ensuring that every sheet of float glass meets stringent safety and performance criteria. Moreover, eco-conscious consumers can rely on float glass products that are increasingly manufactured using sustainable practices, including recycling and reducing carbon emissions, further solidifying the material's reputation as a credible and responsible choice for construction and design.

In conclusion, float glass is more than just a transparent sheet; it is a testament to human ingenuity and a cornerstone of contemporary design. Its transformative journey from raw materials to a polished sheet underscores a blend of experience, expertise, authoritative validation, and unwavering trust. As the world continues to push architectural boundaries and prioritize sustainability, float glass remains at the forefront, bridging the realms of innovation, functionality, and environmental consciousness.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu