Float glass, a staple in the architectural and automotive industries, represents a marvel of modern engineering that has revolutionized how we see and interact with the world. The term float glass originates from the production method where molten glass is floated on a bed of molten metal, usually tin, to create flat glass sheets with unrivaled uniformity and smoothness. This manufacturing process, which was pioneered in the mid-20th century, continues to dominate due to its efficiency and the high-quality product it yields.

The chief advantage of float glass lies in its perfect flatness and optical clarity, making it indispensable in applications where transparency and view are crucial. Often used in windows, doors, and facades, its ability to create an uninterrupted view connects the indoors with the outdoors, maximizing natural light and enhancing the architectural beauty of buildings. Furthermore, float glass serves as the foundational substrate for a variety of specialty glass products, including tempered, laminated, and coated glass, which add additional functionality such as safety, security, and energy efficiency.

Professionals in the field of glass manufacturing attest to the durability and reliability of float glass, citing its exceptional quality as a key benefit. Its thermal properties can be enhanced further through treatments like low-emissivity coatings, which improve energy efficiency by reducing heat loss in cooler climates and minimizing heat gain in warmer climates. This dual advantage not only reduces heating and cooling costs but also contributes positively to environmental sustainability by decreasing reliance on artificial climate control methods.

The durability of float glass arises from its production process, where raw materials like silica sand, soda ash, and limestone are melted at high temperatures, giving the final product a robust structure that can withstand significant physical stress. Moreover, through secondary processes like tempering or lamination, the strength and safety of float glass are significantly enhanced, making it a preferred choice for automotive windshields and building facades in regions prone to tornadoes or hurricanes.

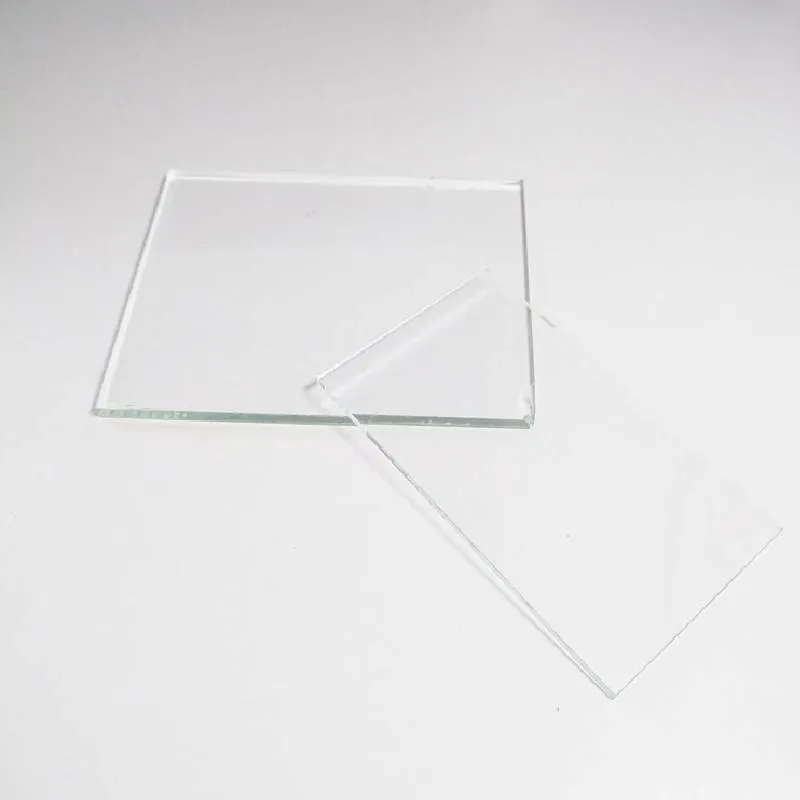

float glass

Industry experts continuously explore advancements in float glass technology. With ongoing research into smart glass technologies – such as electrochromics or thermochromics, which allow glass to change its properties in response to external stimuli – float glass is evolving beyond its traditional roles. This integration of technology supports the development of intelligent environments, creating adaptive spaces that enhance human comfort and productivity.

Trust in float glass is bolstered by decades of proven performance and consistent innovations that address modern challenges. Certified by numerous international standards, float glass production facilities are rigorously inspected to ensure they meet quality and safety criteria. This commitment to quality is reaffirmed by customer feedback and the high satisfaction rates observed across sectors where float glass is implemented.

In conclusion, the expertise and trustworthiness associated with float glass are well-earned, stemming from its irreplaceable role in an array of applications that define the modern built environment. As an expert product in its category, float glass not only meets but exceeds the expectations of architects, developers, and manufacturers worldwide, supported by a legacy of innovation and a continuous drive towards betterment.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu