Float glass stands as a hallmark innovation in the glassmaking industry. Its unique manufacturing process and extensive applications make it a pivotal product within numerous sectors. With an unwavering commitment to Experience, Expertise, Authoritativeness, and Trustworthiness, this article delves into the intricacies of float glass, providing comprehensive insights for those seeking to deepen their understanding of this remarkable product.

The float glass production process revolutionized the glass industry in the mid-20th century, thanks to the pioneering efforts of Sir Alastair Pilkington. By floating molten glass on a bed of molten tin, manufacturers achieved perfectly flat and clear sheets, eliminating the distortions and inconsistencies prevalent in earlier methods. This process not only standardized glass thickness but also made the production of large sheets economically viable. The expertise required to maintain the precision of this process ensures that float glass remains a trusted choice for various architectural and automotive applications.

Float glass's authority in the market is further cemented by its versatility. It serves as a foundational material for numerous derivatives, including tempered glass, laminated glass, and coated glass products. Each of these variations caters to specific industry needs, enhancing safety, energy efficiency, and aesthetic appeal. For instance, in the automotive sector, tempered float glass offers shatter resistance, crucial for passenger safety. Simultaneously, coated float glass in buildings improves energy retention, reflecting heat away during summers and retaining warmth during winters.

The trustworthiness of float glass is evident in its widespread adoption across industries that demand precision and reliability. In architecture, float glass provides transparency and light, crucial for modern design principles. Its adaptability is showcased in projects ranging from skyscraper facades to residential windows, where its quality ensures both aesthetic and functional performance. Furthermore, float glass’s enduring stability and resistance to environmental factors make it an indispensable component in environments subjected to extreme weather conditions or fluctuating temperatures.

Professionals in the field recognize the academic and technical expertise surrounding float glass. Consultations with industry leaders reveal a robust body of research and development dedicated to advancing the capabilities of float glass. Innovations such as self-cleaning and anti-reflective coatings are testaments to the ongoing exploration of enhancing the inherent properties of float glass. This expertise continues to build the product’s credibility, providing stakeholders with confidence in their choice.

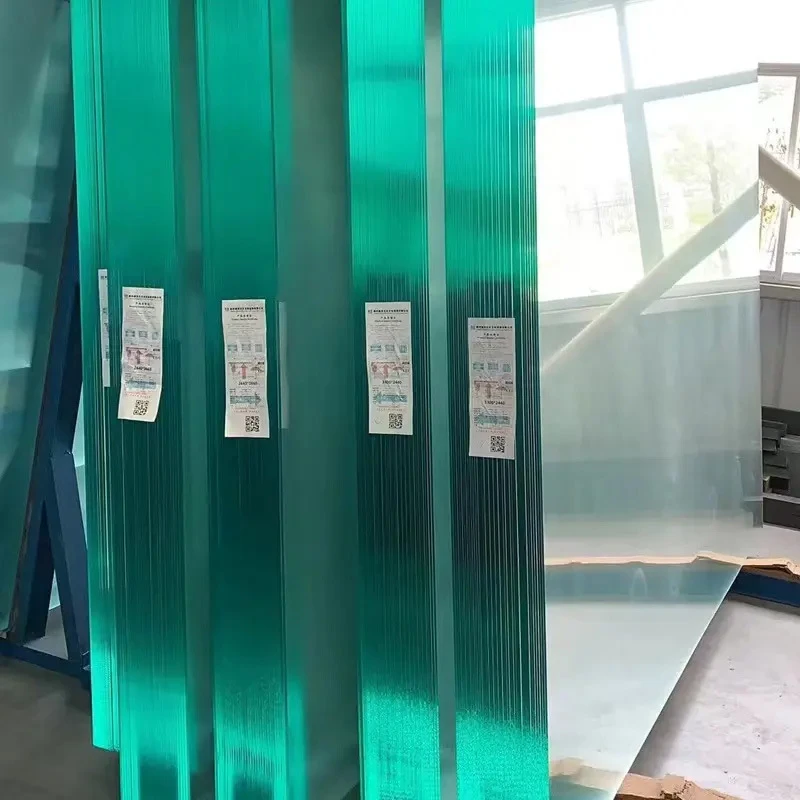

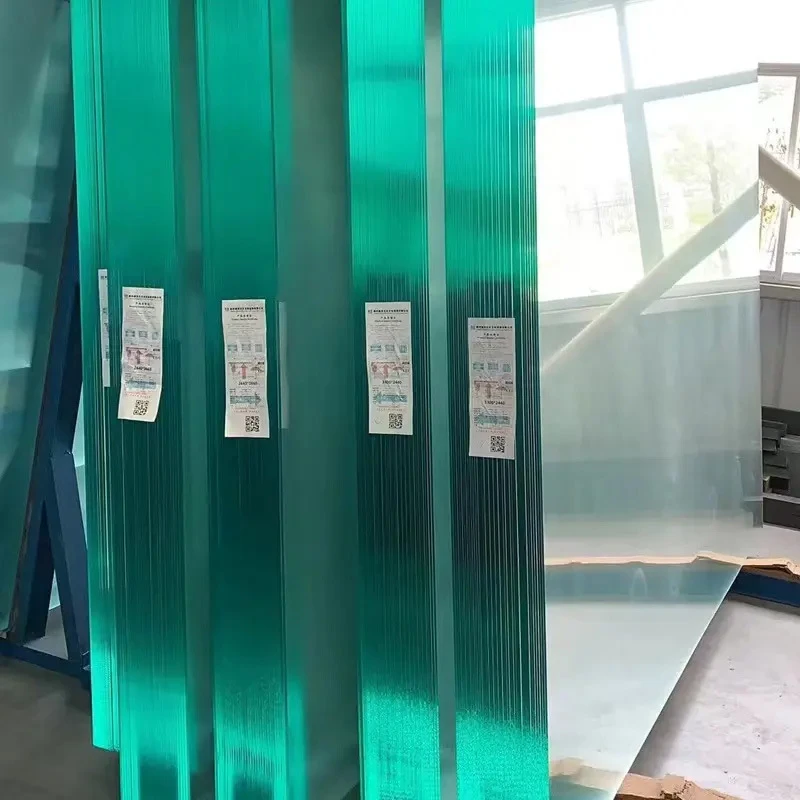

float glass

Real-world experiences underscore the transformative impact of float glass. Architects and engineers routinely cite projects where float glass facilitated groundbreaking designs, merging form and function seamlessly. Case studies from urban development projects illustrate how float glass plays a critical role in achieving green building certifications, contributing to sustainable construction goals. This reflects not only the technical merits of float glass but also its alignment with broader environmental and social imperatives.

For consumers, the reliability and superior quality of float glass translate into tangible benefits. Enhanced safety features in automobiles, improved energy efficiency in homes, and aesthetically pleasing commercial spaces are direct outcomes experienced by end-users. The widespread trust placed in float glass by both industry professionals and everyday consumers alike underscores its established role in modern society.

As the glass industry continues to evolve, float glass remains at the forefront, an example of enduring innovation and reliability. Whether exploring new applications or sustaining existing ones, the consistency and adaptability of float glass ensure it meets and exceeds industry standards. Experts anticipate that its role will only expand as urbanization increases and technological advancements forge new directions for glass applications.

In conclusion, float glass exemplifies an intersection of innovation, reliability, and versatility. Anchored by a rich history and backed by expert consensus, it continues to shine as a pivotal component in both traditional and cutting-edge applications. For those exploring the potential of float glass, its proven track record offers both peace of mind and inspiration for future possibilities.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu