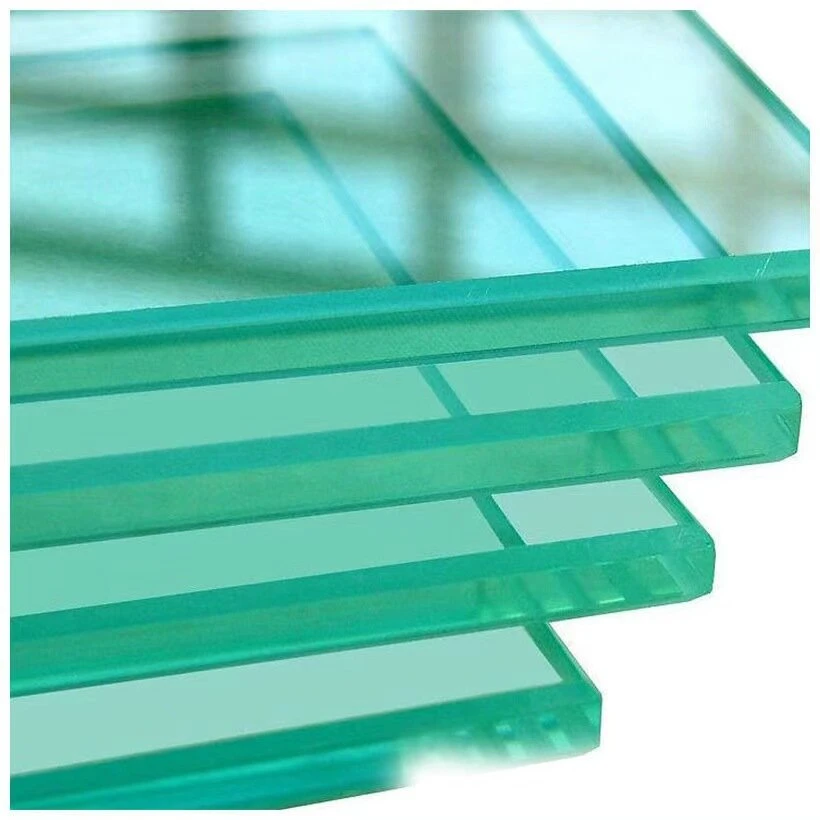

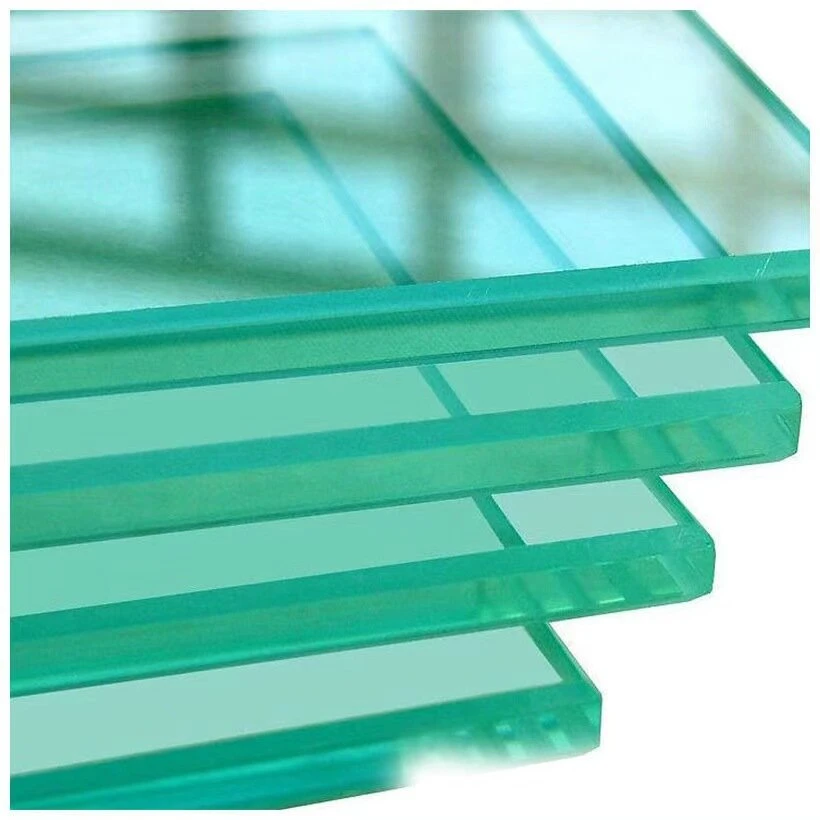

Float glass has emerged as a game-changer in the world of glass fusing, thanks to its high quality and diverse applications. As someone who has spent years exploring different types of glass and their unique properties, I can affirm the profound impact float glass has had in both artistic and industrial domains.

Experience in working with float glass for fusing reveals its versatility and strength, making it an ideal choice for various projects. Unlike traditional glass, float glass is created by floating molten glass on a bed of molten metal. This process ensures a uniform thickness and a flat surface, which are key elements for successful fusing. Over the years, I’ve observed that this type of glass is particularly valued for its clarity and lack of distortion, making it preferable for intricate projects where precision is paramount.

From a professional standpoint,

the expertise involved in selecting the right glass for fusing is crucial. Float glass, with its consistent quality, eliminates many of the challenges faced in glass fusing. It is most commonly used for creating decorative items, such as jewelry or small artworks, owing to its ability to maintain vibrant colors post-fusing. Professionals in the industry often pair float glass with dichroic coatings or other glass types to add reflective qualities and create stunning visual effects.

The use of float glass extends beyond the arts, playing a significant role in industrial applications. Its refined manufacturing process ensures that it is highly resistant to heat, a necessity in high-temperature environments. This trait enhances its trustworthiness as a material for structural components, such as glass facades, where both strength and aesthetic appeal are essential. Moreover, its optical clarity is unmatched, providing an unobstructed view that is invaluable in architectural designs.

float glass for fusing

Authoritativeness in this domain comes from a depth of understanding of float glass’s material properties and its behavior under different firing conditions. It requires a precise approach to temperature control and timing to achieve the desired result without compromising the integrity of the glass. Pros in the field develop these skills over time, drawing from both formal education and hands-on experience to guide others in their fusing projects.

Trustworthiness is further established through consistent results and the reliability of float glass across various applications. Dependable supply chains and stringent quality control measures contribute to its status as a reliable medium for artists and industrial engineers alike. End-users, from hobbyists to large-scale manufacturers, rely on float glass’s predictability, knowing that it will perform as expected, whether it’s for a decorative piece or a bearing component in architecture.

In conclusion, float glass is more than just a material; it is a cornerstone of modern glass fusing, offering endless possibilities for creativity and innovation. Its unique properties cater to both artistic endeavors and essential industrial requirements, making it a trusted choice for experts seeking high-quality results. As we continue to explore its potential, float glass remains a testament to the synergy between craftsmanship and technology.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu