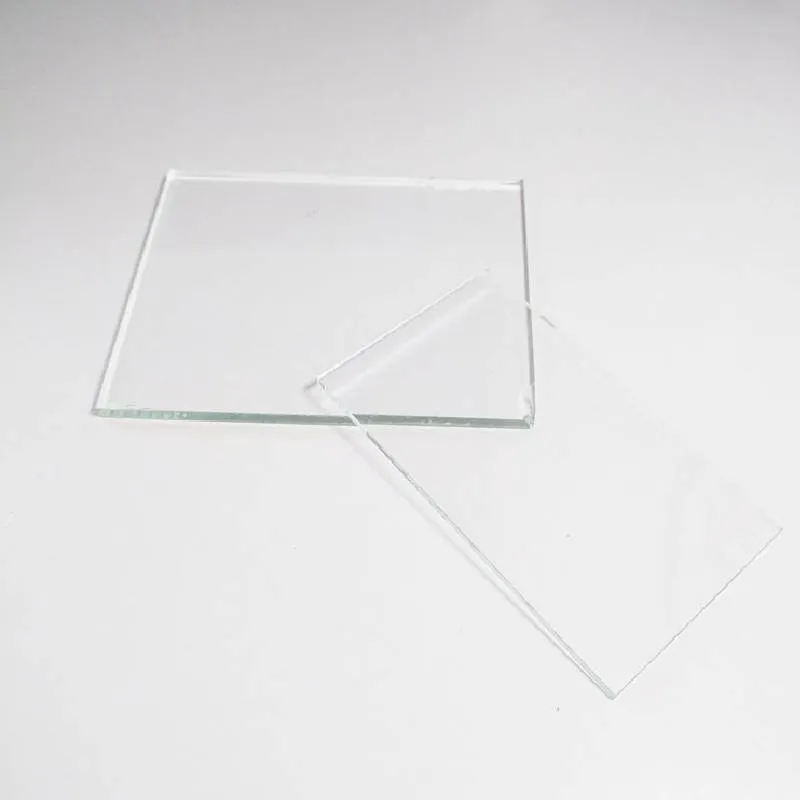

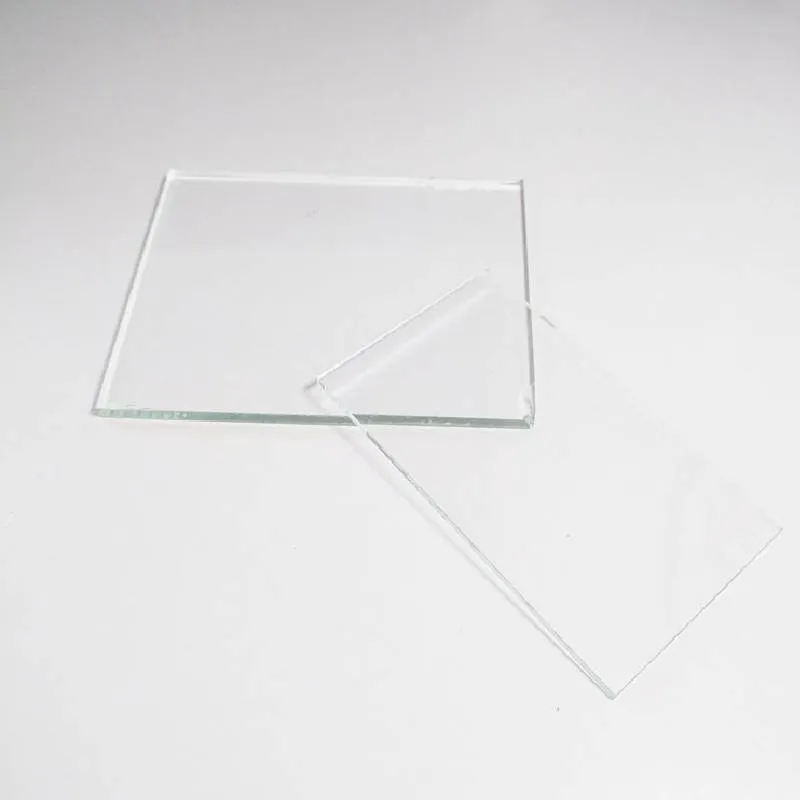

Floating glass, a staple in modern architecture and design, transforms spaces with its clear, uninterrupted expanses and refined aesthetics. As an integral part of contemporary construction, the manufacturing process of float glass is an intricate dance of innovation, precision, and expertise.

The journey of creating float glass begins with the careful selection of raw materials. High-purity silica sand is combined with soda ash, limestone, and dolomite, each serving a specific purpose in the final product. Silica forms the base, while soda ash reduces the glass transition temperature, limestone enhances stability, and dolomite provides magnesium for increased durability. Each component is meticulously measured and blended, underscoring the expertise required at the foundational phase of production.

Once mixed, these raw materials are heated in a furnace at temperatures exceeding 1500°C. This intense heat transforms the batch into a liquid glass, ready to be shaped. Herein lies the revolutionary technique pioneered in the 1950s floating the molten glass on a bed of molten tin. As the glass spreads evenly across the tin surface, it forms a smooth, flat sheet with uniform thickness. Mastery over this float process is pivotal, as the entire operation hinges on maintaining optimal temperatures and conditions—a testament to the authoritative knowledge of the manufacturers.

As the glass floats, it cools diligently, progressing through a controlled annealing chamber. This stage is critical; slow, uniform cooling prevents internal stresses, ensuring the glass remains stable and resilient. Expertise in this realm is non-negotiable, as even slight deviations can compromise structural integrity, highlighting the precision and trustworthiness ingrained in the manufacturing process.

float glass manufacturing

Quality control is the next hallmark of float glass production. Advanced inspection systems scan each sheet for imperfections. Whether detecting micro-bubbles, surface distortions, or thickness variations, these systems ensure only the highest quality reaches the market. Such rigorous quality checks reflect the reliability and commitment of manufacturers to deliver safe, dependable products to consumers.

Float glass's versatility extends beyond its clear, polished form. It can be transformed post-manufacture to meet diverse architectural needs. Techniques such as tempering increase its strength, making it suitable for safety applications in buildings and automobiles. Laminating creates glass that remains intact on impact, while various coatings can enhance energy efficiency or provide ultraviolet protection. This adaptability underscores the product's expertise and innovation, catering to ever-evolving market demands.

In conclusion, the float glass manufacturing process is a meticulously refined art form, melding advanced technology with profound expertise. Each stage of production is governed by stringent checks and balances, emphasizing the reliability and superiority of the final product. In a world where transparency, strength, and adaptability are paramount, float glass not only meets but exceeds expectations, embodying the pinnacle of modern manufacturing prowess. With a commitment to quality and a foundation built on deep technical knowledge, float glass continues to illuminate the spaces it graces, reinforcing its status as a cornerstone in the architecture of tomorrow.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu