Float glass manufacturing is a sophisticated process that has revolutionized the glass industry by producing high-quality, uniform glass sheets extensively utilized in constructing windows, facades, mirrors, and high-tech applications. This process holds significant industry expertise in the core of its practices, delivering a blend of precision engineering and chemical finesse that ensures the highest standards of product quality and safety.

In the float glass manufacturing process, raw materials like silica sand, soda ash, dolomite, and limestone are precisely weighed and mixed before being fed into a furnace. The furnace operates at approximately 1,700 degrees Celsius, where these raw materials melt into a molten glass mixture. This high temperature initiates a series of chemical and physical transformations, demanding expertise to maintain the right balance for quality output.

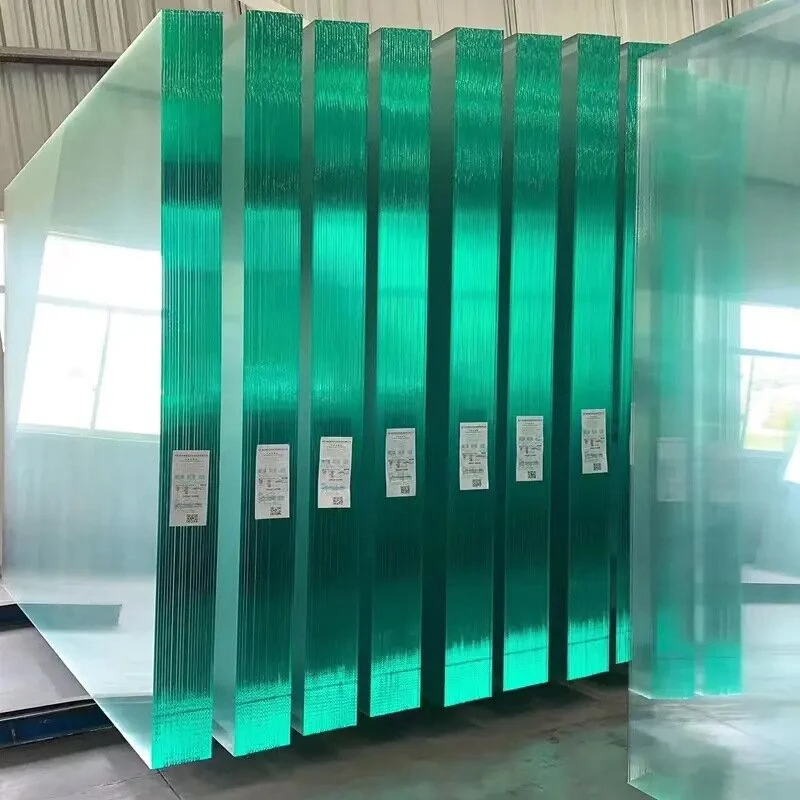

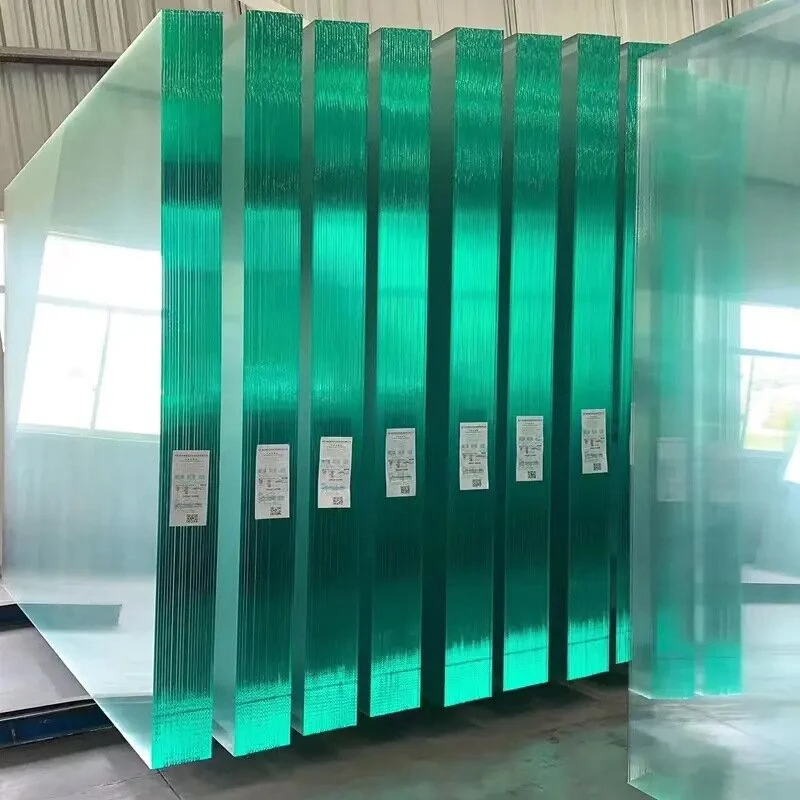

One standout feature of float glass manufacturing is its commitment to experience-driven innovation. The glass is floated over a bed of molten tin, which acts as a perfectly flat surface. This innovatively engineered method allows gravity to spread the glass out over the tin, preventing any air bubbles and ensuring a smooth surface, both on top and underneath. The expertise involved in maintaining the tin bath at just the right conditions is paramount; too hot, and the tin could melt excessively into the glass, too cool, and the glass could solidify unevenly, leading to defects.

Upon emerging from the tin float, the glass enters an annealing chamber, also known as a lehr, where it is gradually cooled. Expertise in temperature control ensures that the glass cools evenly from about 600 degrees Celsius to ambient temperature, avoiding stress points that could lead to spontaneous fractures or weaknesses. The authoritative control of this cooling process is a criteria for defining the structural integrity of the final product.

For trustworthiness, float glass manufacturing adheres to rigorous quality control standards, often set by international guidelines, to ensure consistent product quality and safety. By employing state-of-the-art inspection systems, including optical gauges, digital flaw detection, and laser measuring tools, manufacturers guarantee the reliability of the float glass. This technological precision showcases the industry's commitment to authority by quantifying and documenting every aspect of the production process.

float glass manufacturing

In recent developments, sustainability has become integral to float glass manufacturing. The modern facility reduces emissions and optimizes energy use, enhancing the ecological trustworthiness of the production. Many manufacturers now incorporate recycled glass, known as cullet, into their raw material mix, significantly reducing the energy required for production and lowering the environmental footprint. This sustainable approach, backed by experience and expertise,

ensures that float glass manufacturers are leading the way in responsible production practices.

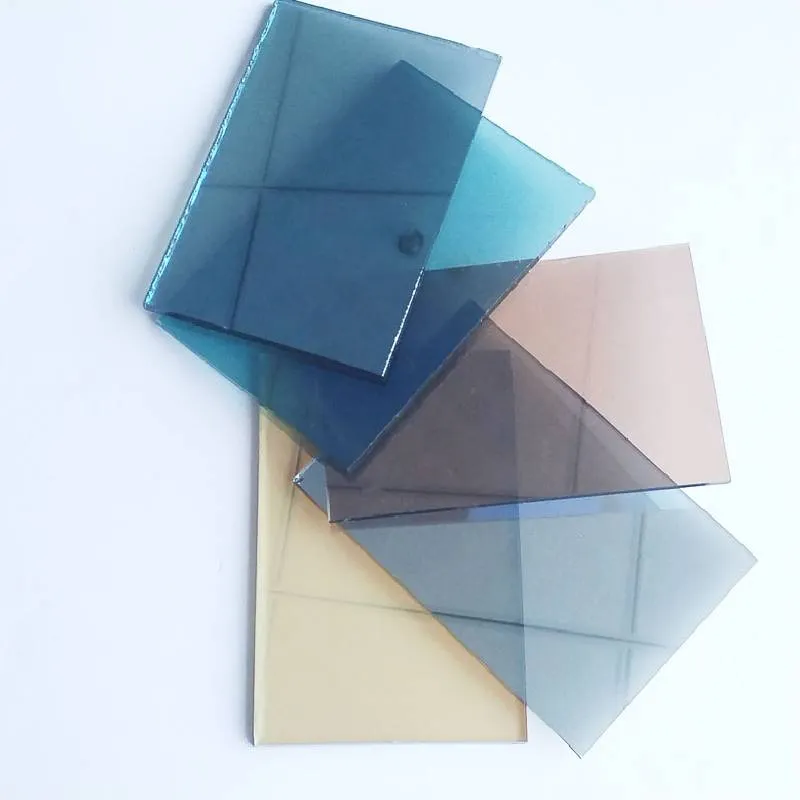

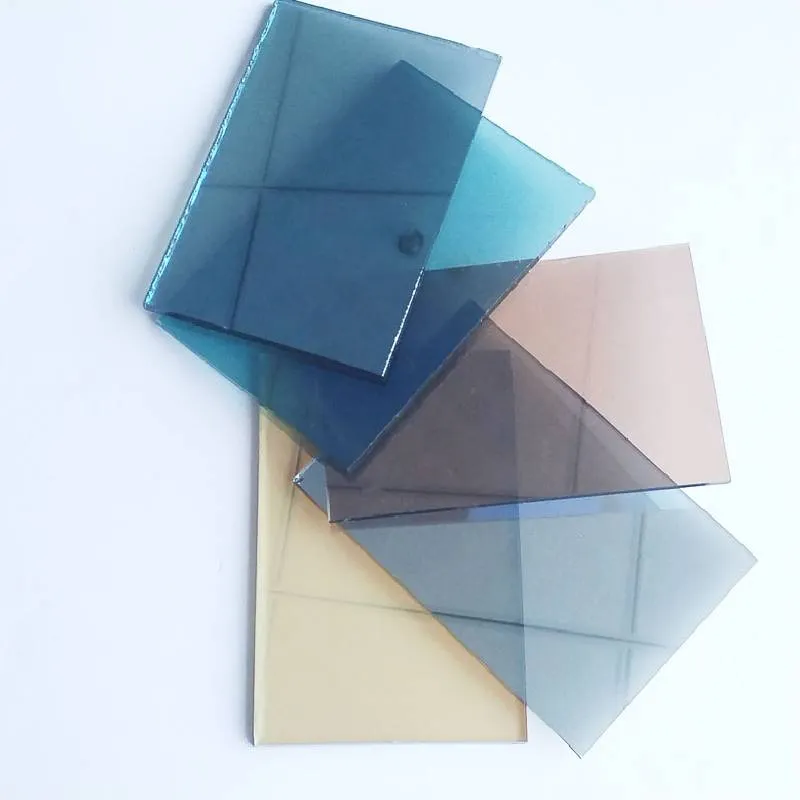

Beyond practical applications, float glass is pivotal in innovative architectural designs and advanced technological uses such as photovoltaic cells and display screens. The finished product can be treated or coated in various ways to enhance energy efficiency, thermal insulation, or aesthetic appeal, highlighting the versatility and authoritative capability of float glass manufacturers.

Utilizing advanced technologies, manufacturers continue to explore the limits of float glass production, paving the way for innovations that meet modern architectural and consumer demands. Through continuous investment in research and development, the float glass sector remains at the forefront of delivering superior products that embody the principles of experience, expertise, authority, and trust.

In conclusion, the float glass manufacturing process exemplifies the pinnacle of industrial craftsmanship and scientific mastery. With a focus on precision, quality control, and sustainability, it continues to push the boundaries of what is possible in the world of glass production, reinforcing its central role in modern construction and technology.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu