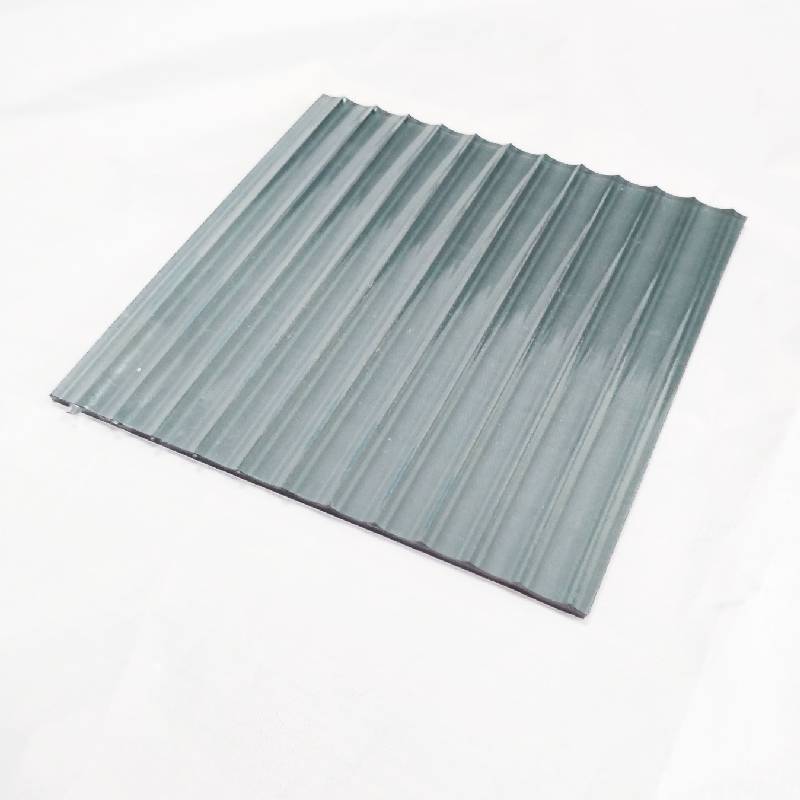

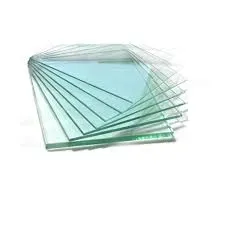

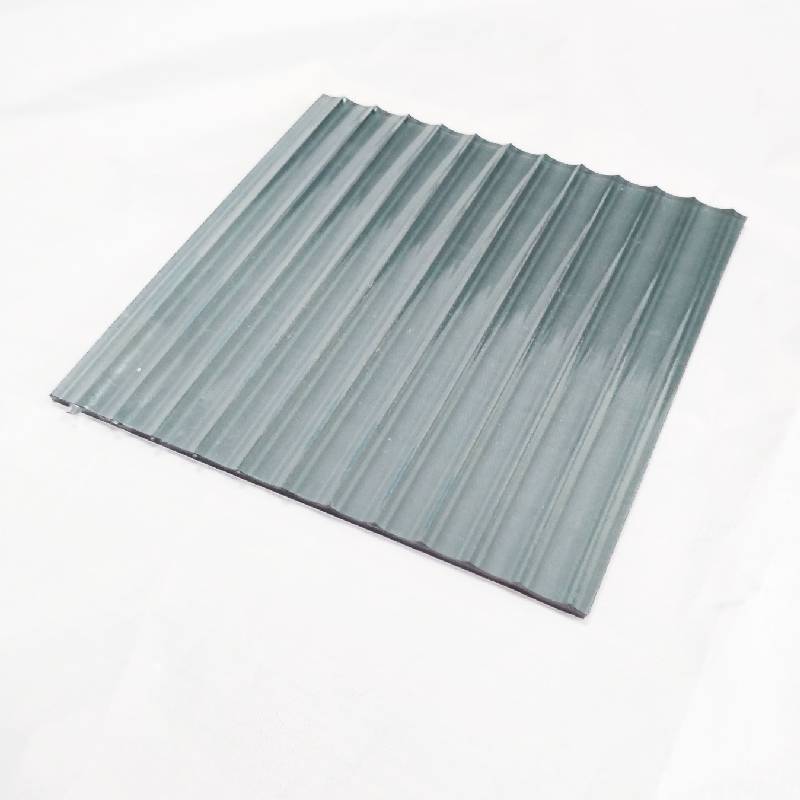

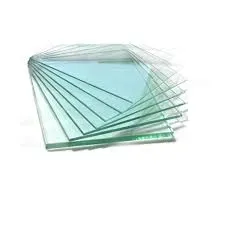

Float glass manufacturing is a meticulously engineered process that has revolutionized the production of high-quality glass products. Central to this process is the principle of floating molten glass on a bath of molten tin, resulting in perfectly flat and uniform glass sheets. This technique not only improves the optical clarity and structural integrity of the glass but also allows for consistent thickness across large sheets, which is pivotal for many modern applications.

Companies engaging in float glass manufacturing often invest heavily in state-of-the-art facilities equipped with advanced machinery and cutting-edge technologies. The process begins with the melting of raw materials such as silica sand, soda ash, and limestone in a furnace at temperatures exceeding 1,700°C. Upon reaching a liquefied state, the molten glass is gently poured onto a layer of molten tin. The immiscible nature of glass and tin ensures that the glass floats and spreads evenly without sinking or merging into the tin. This step is crucial for achieving the desired thickness and flatness, which are verified through precision monitoring systems.

Experience in the field of float glass manufacturing underscores the importance of strict quality control measures. Skilled technicians oversee every phase of production, from raw material selection to the final cooling stage. Advanced sensors and automated systems play a pivotal role in detecting and correcting any abnormalities, ensuring that the end product meets stringent industry standards. These measures not only guarantee high-quality glass but also enhance the safety and durability of the products derived from it, such as windows, mirrors, and panels.

Expertise in this domain draws upon decades of research and development. Manufacturers continuously explore innovative approaches to enhance efficiency and sustainability in glass production. Recent advancements have seen the introduction of energy-efficient furnaces and recycling initiatives that reduce the environmental footprint of glass manufacturing. Such progressive measures align with global sustainability goals and demonstrate a commitment to responsible industry practices.

float glass manufacturing

Authoritativeness in float glass manufacturing is often synonymous with the reputation of leading companies that set benchmarks for quality and innovation. These industry leaders frequently collaborate with research institutions to pioneer new technologies and applications. Their contributions to the field are recognized through patents and publications, and they often guide regulatory standards to promote best practices across the industry.

Trustworthiness in this sector is reinforced through certifications and affiliations with recognized bodies such as the International Organization for Standardization (ISO). Reputable manufacturers conduct regular audits and compliance checks to ensure adherence to international safety and quality standards. This dedication to maintaining high standards fosters consumer confidence and positions these companies as reliable partners in the supply chain.

Thus, float glass manufacturing stands as a sophisticated and dynamic field that demands a synthesis of experience, expertise, authoritativeness, and trustworthiness. Through continual innovation and adherence to rigorous quality standards, the industry not only meets current demands but also anticipates future requirements, paving the way for the next generation of glass products.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu