Floating glass manufacturing is a significant component of the global glass industry, and establishing a new plant involves considerable investment. Understanding the costs involved is crucial for investors and stakeholders who seek profitable ventures in this domain.

Floating glass, known for its high-quality, smooth surface and optical clarity, is produced using the float process, which involves floating molten glass on a bed of molten tin. This method is not only capital-intensive but also requires a deep understanding of technological, environmental, and economic factors.

Capital Investment

The cost of setting up a float glass manufacturing plant can range from tens to hundreds of millions of dollars. This variance depends on factors such as plant capacity, location, technology adoption, and raw material sourcing. Large-scale plants, which can produce significant volumes of glass per day, evidently require higher investment. A critical initial cost component is the acquisition of land, with its price influenced by proximity to raw material sources and markets.

Infrastructure and Equipment

The establishment of a float glass plant necessitates considerable spending on infrastructure, including the construction of the production facility and installation of essential utilities like power and water supply. Additionally, state-of-the-art manufacturing machinery is a significant expense. This includes the glass melting furnace, annealing lehr, and cutting and handling equipment. Technological upgrades to these systems can increase efficiency but also raise initial costs.

Operational Costs

Operational costs are another crucial consideration, encompassing raw material acquisition, labor, energy consumption, and maintenance. Silica sand, soda ash, and limestone are primary raw materials, and their prices can fluctuate based on market conditions. Energy constitutes a substantial part of operational expenses, as the float glass process is energy-intensive. Thus, securing cost-effective and reliable energy sources is vital for maintaining profitability.

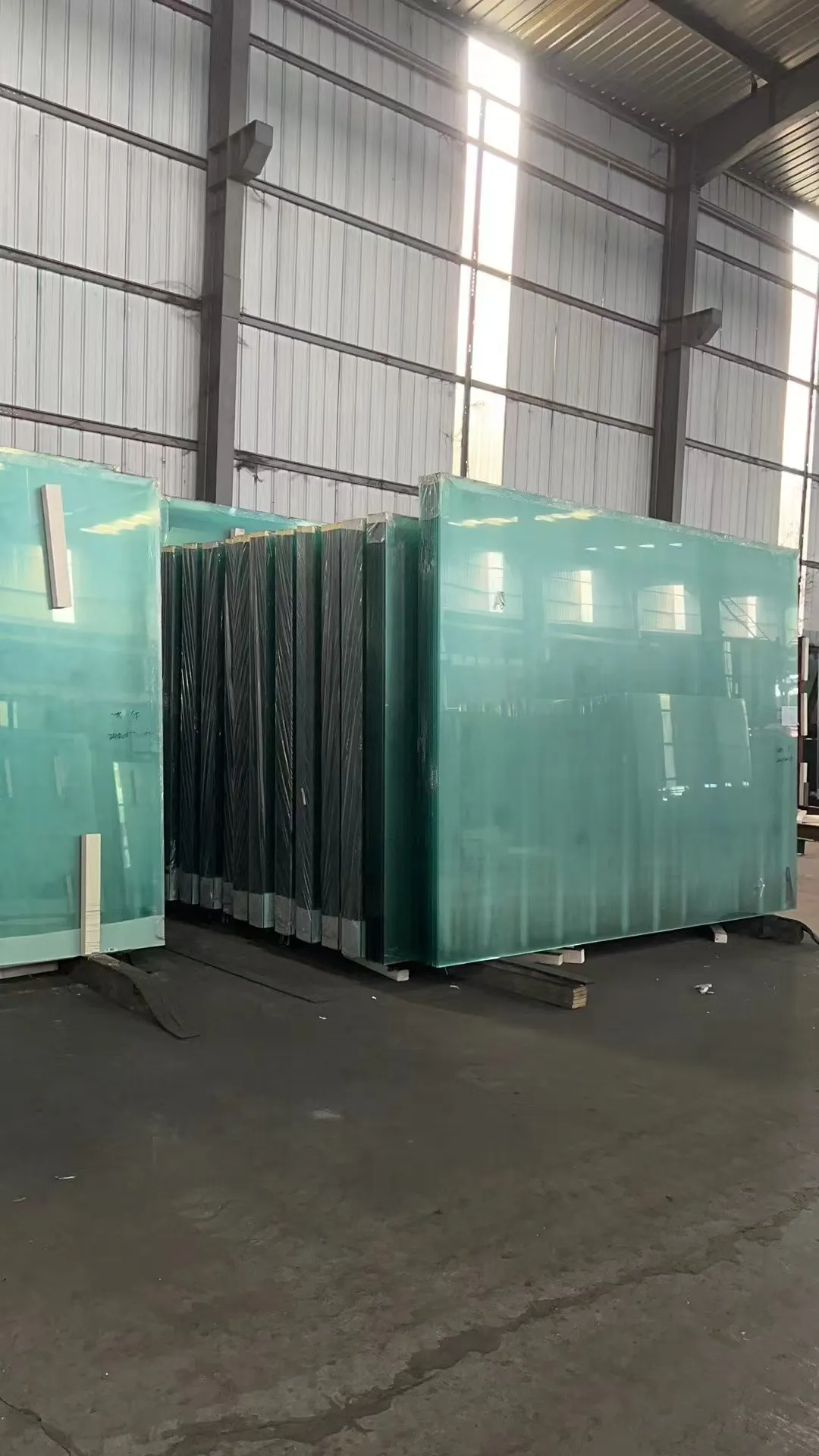

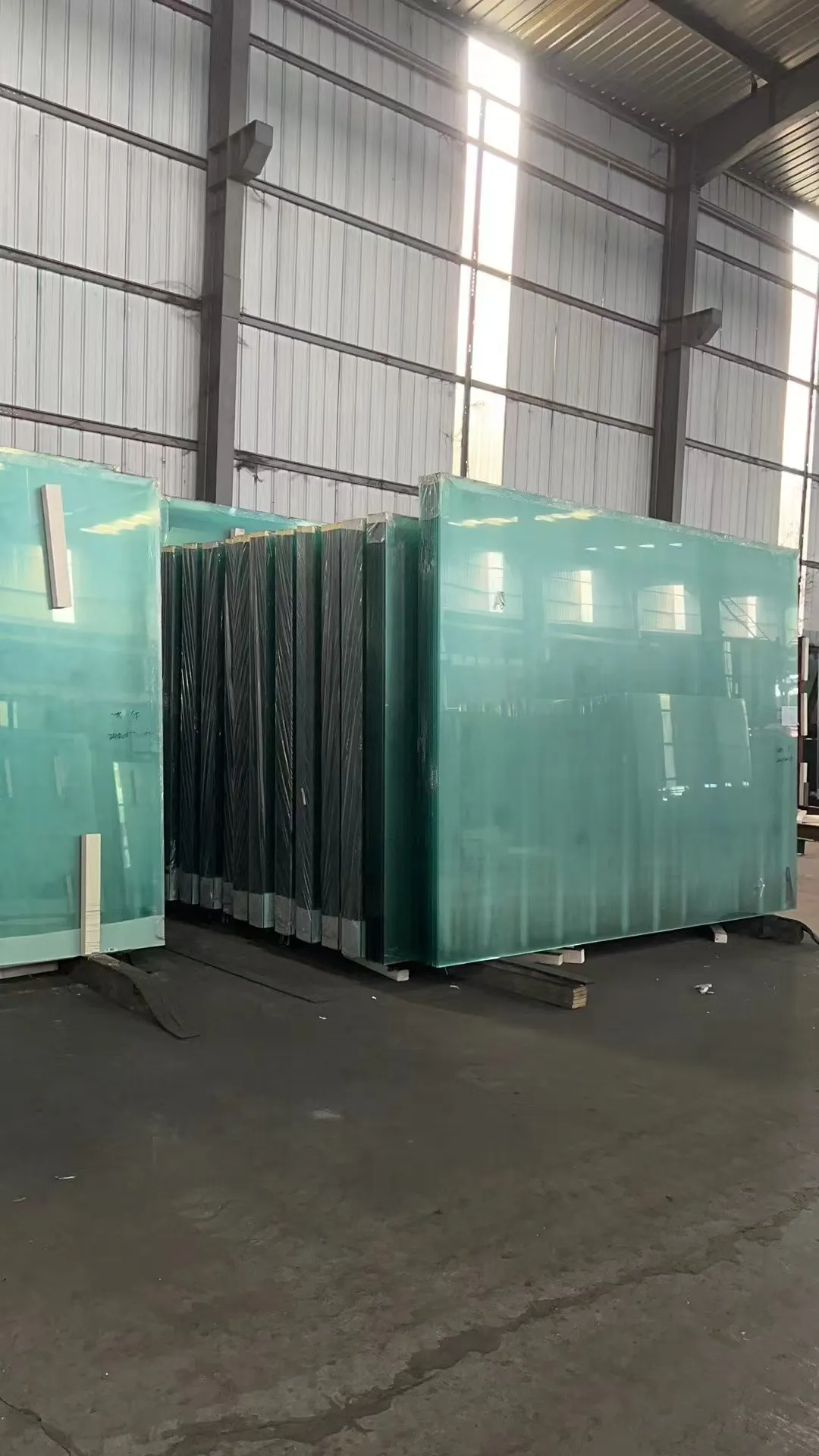

float glass manufacturing plant cost

Environmental and Regulatory Compliance

The float glass industry is subject to strict environmental regulations due to its potential impact on air and water quality. Compliance with these regulations may entail additional costs for implementing eco-friendly technologies or pollution control measures. Failure to adhere to regulatory standards can lead to hefty fines and operational shutdowns, underscoring the need for a strategic approach to environmental management.

Market Considerations

Understanding market dynamics is essential for the successful operation of a float glass plant. Factors such as regional demand, competition, and price trends greatly influence potential returns on investment. Establishing strategic partnerships with construction companies, automotive manufacturers, and other industries reliant on glass products can ensure sustained demand and market access. Additionally, innovation in product types, such as energy-efficient glass or smart glass, can offer competitive advantages.

Financial Planning and Risk Management

Effective financial planning and risk management strategies are imperative. Investors must consider potential risks such as fluctuating raw material costs, shifts in consumer demand, and technological obsolescence. Viability assessments, thorough market analysis, and scenario planning are essential components of a robust investment strategy, mitigating unforeseen challenges.

Setting up a float glass manufacturing plant is a multifaceted endeavor requiring careful planning, rigorous feasibility studies, and strategic execution. While the initial investment may be substantial, the potential for high returns exists if the facility is managed efficiently and innovatively, taking into account both current market demands and evolving industry trends.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu