The float glass manufacturing process stands as a cornerstone of modern architectural and automotive industries, offering unparalleled clarity and smoothness compared to other types of glass. Over the years, the advancements in this manufacturing technique have solidified its position as the most efficient method for producing high-quality flat glass.

Originating in the mid-20th century, the float glass process was invented by Alastair Pilkington, revolutionizing how glass is produced. The process begins with the melting of raw materials such as silica sand, soda ash, dolomite, and limestone in a furnace at temperatures exceeding 1700°C (3090°F). This molten glass is then carefully poured onto a bath of molten tin, where it 'floats' and spreads out to form a uniform glass ribbon.

This meticulous process is highly regarded for its precision and ability to produce glass with a flawless finish, eliminating the need for additional grinding and polishing. The uniform thickness and smooth surfaces are achieved due to the natural leveling and cooling process as the glass floats on the denser tin. This innovative use of materials exemplifies the expertise involved in float glass manufacturing, ensuring a product of exceptional quality and consistency.

In the controlled atmosphere of the float bath, temperature gradients and atmospheric pressure are carefully regulated. This environment prevents any chemical reaction between the glass and tin, which could otherwise compromise the glass’s clarity and structural integrity. As the glass emerges from the bath, it undergoes a carefully controlled cooling process known as annealing, within an annealing lehr. This step is critical to relieving internal stresses that could lead to imperfections or weaknesses in the final product.

The entire process, from melting to cutting, is constantly monitored and adjusted by skilled technicians employing advanced technologies. These professionals rely on in-depth knowledge and expertise to maintain stringent quality control measures, thereby ensuring that every sheet of float glass meets the highest industry standards.

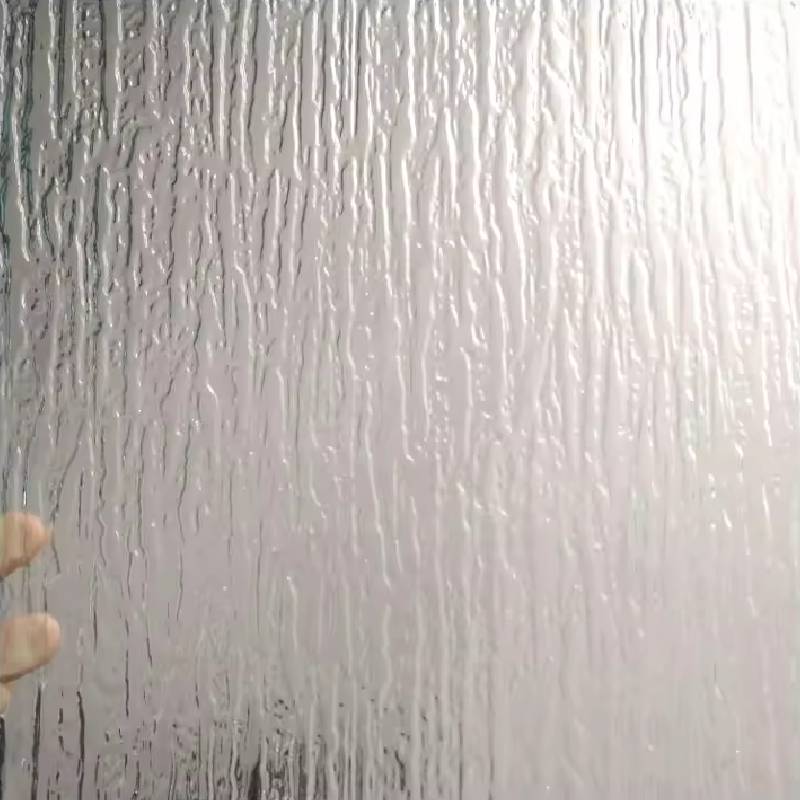

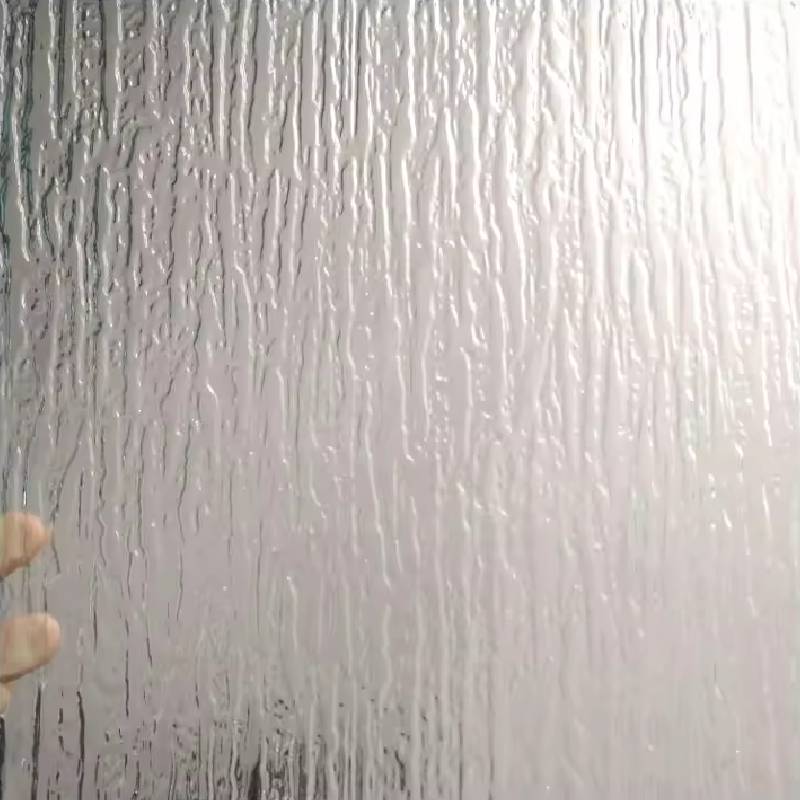

float glass manufacturing process

Sustainability has also become a central focus in the float glass manufacturing industry. Manufacturers leverage cutting-edge technology to improve energy efficiency, significantly reducing the carbon footprint of the production process. By utilizing recycled glass (cullet) mixed with raw materials, producers decrease energy consumption and minimize waste, adhering to increasingly strict environmental regulations.

Float glass is versatile and employed in a variety of applications due to its optic perfection, sound insulation properties, and thermal insulation capabilities. It is further processed into tempered or laminated glass for safety, reflective glass for energy efficiency, or tinted glass for aesthetic purposes. These additional treatments are testament to the expertise ingrained in each step of the manufacturing process, demonstrating the adaptability and advanced applications of float glass in various sectors.

In the realm of construction and architecture, float glass is indispensable, providing architects and designers with material that is both aesthetically pleasing and functionally robust. Automotive industries extensively use float glass for windshields and windows, benefiting from its durability and clarity. The integration of cutting-edge coatings and films has expanded its use into energy-efficient glazing solutions that reduce heating and cooling demands in buildings, showcasing float glass as a critical component in sustainable building practices.

In conclusion, the float glass manufacturing process exemplifies the synthesis of innovation, expertise, and sustainability. It stands as a testament to the relentless pursuit of perfection and efficiency in industrial practices, delivering a product that not only meets but exceeds the increasing demands of modern industry and architecture. As technological advancements continue to refine this process, float glass remains pivotal, embodying the highest standards of quality and excellence in manufacturing.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu