When exploring the fascinating world of float glass manufacturing, one finds a seamless blend of cutting-edge technology and traditional craftsmanship. This process is not merely an industrial function but rather a delicate science that reflects decades of expertise in producing the finest quality of glass. Within the world of glass production, the float glass process stands out as the gold standard, renowned for creating flawless, high-quality glass that is ubiquitous in both architectural and automotive industries.

The journey of float glass manufacturing begins with raw materials. Sand, soda ash, limestone, and other key ingredients are carefully selected for their purity and specific properties, which ensure that the resulting glass meets stringent quality standards. These materials are mixed with extreme precision, a step critical to producing consistent results. This mixture is melted in a large, highly controlled furnace at temperatures reaching approximately 1500°C. This intense heat transforms the dry materials into a molten glass mixture, exhibiting a glowing, viscous fluidity.

Next is the float bath, a hallmark of this manufacturing process which gives it its name. This step involves pouring the molten glass onto a bath of molten tin. Due to the difference in density, the glass floats effortlessly on the tin, forming an impressively flat surface that eliminates imperfections naturally. The temperature in this section is carefully controlled, with gradual cooling applied to prevent stress fractures or other defects. This naturally results in glass sheets that are almost perfectly uniform in thickness and formation, a crucial quality for any high-end product.

Following the float bath, the glass continues through a series of annealing ovens known as a lehr. During this phase, the temperature is gradually reduced to relieve internal stresses within the glass, ensuring durability and stability in the final product. This meticulous annealing process is governed by a profound understanding of thermal dynamics and material properties, vital elements for experts threading the line between innovation and tradition.

float glass manufacturing process

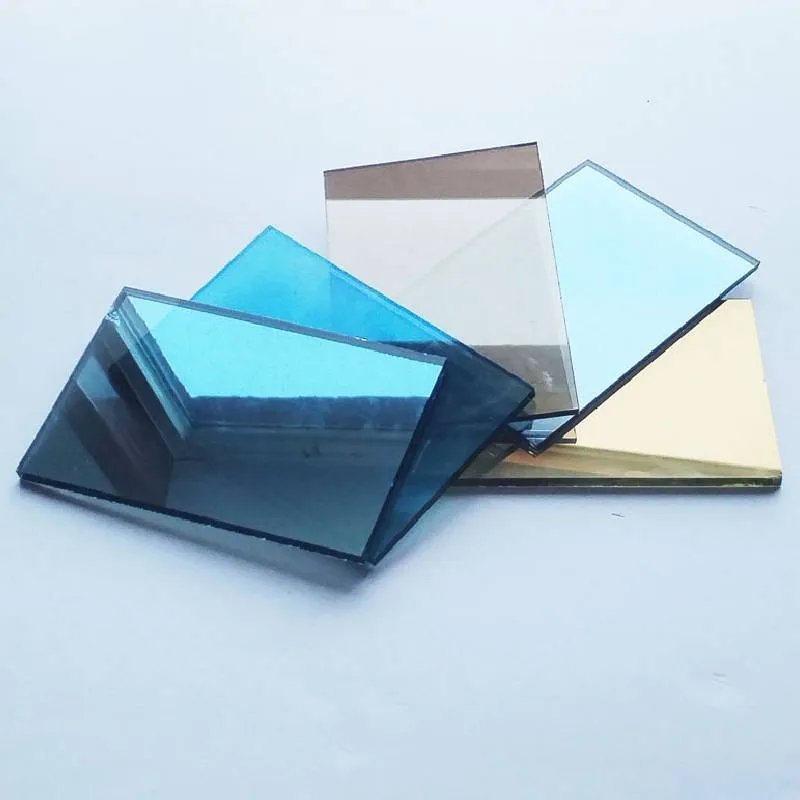

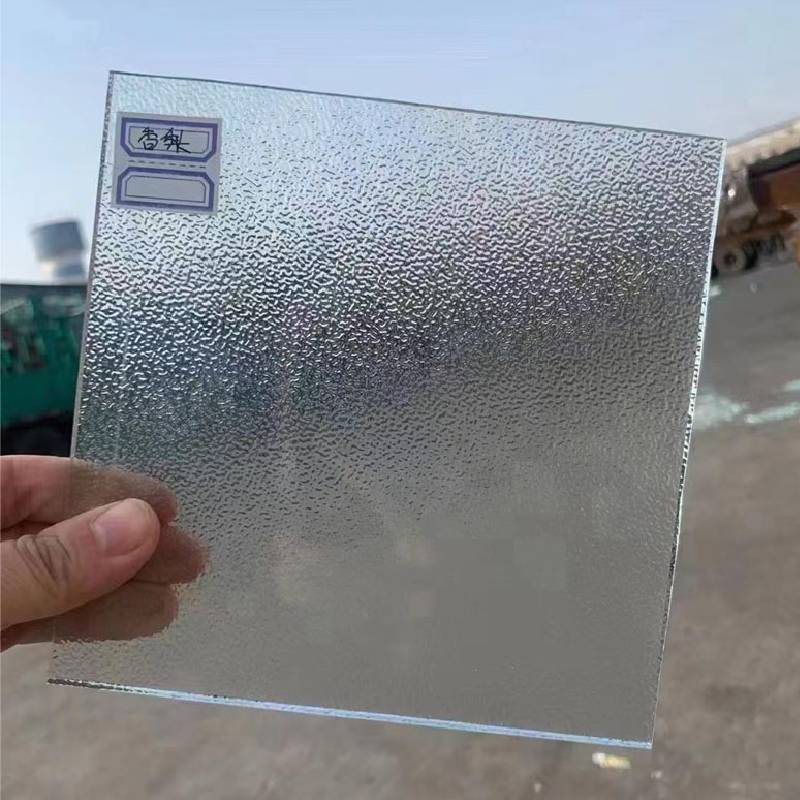

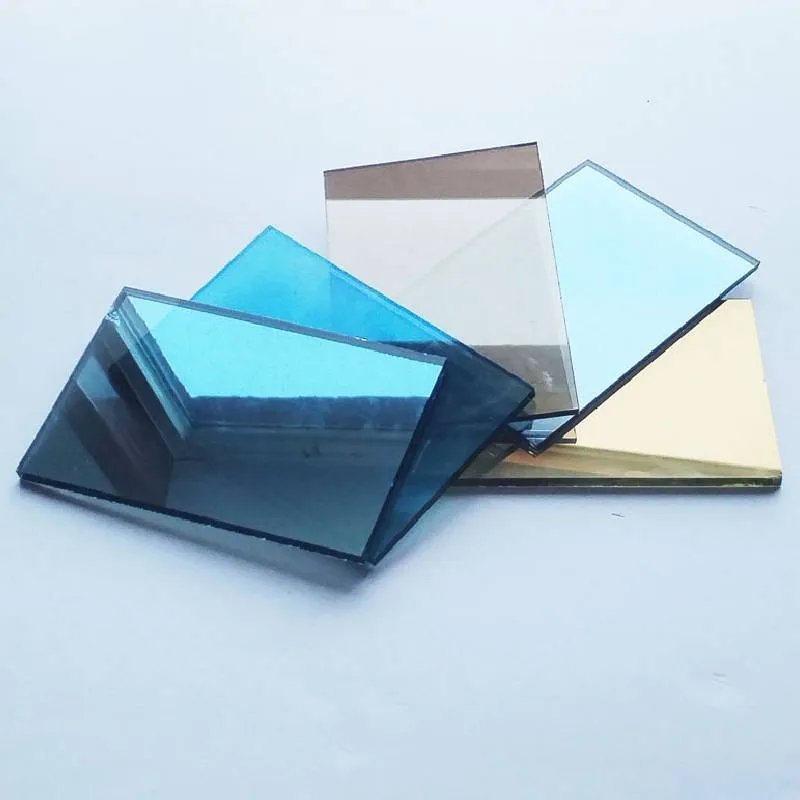

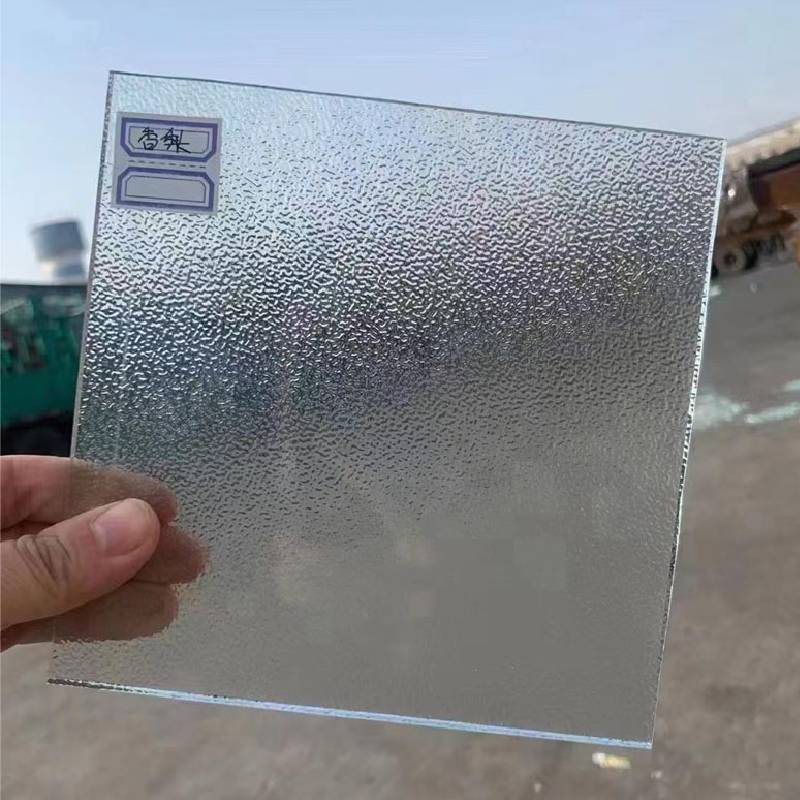

The final stage often involves cutting the cooled glass into precise sizes and applying additional treatments or coatings, depending on its intended use. These might include processes to enhance thermal insulation, improve strength through tempering, or even integrate advanced technologies such as smart glass functionalities that respond to environmental changes. Each of these treatments is executed by seasoned professionals who marry their technical expertise with an artistic touch, emphasizing the extraordinary versatility of float glass.

Moreover, sustainability has taken a prominent role in modern float glass production. With environmental impact becoming a growing concern, manufacturers are implementing innovative methods to reduce energy consumption and greenhouse gas emissions. The recycling of glass cullet, for example, is a prominent practice that decreases the need for raw materials and minimizes waste. By committing to eco-friendly production practices, float glass manufacturers are not only preserving the environment but also adding another layer of trustworthiness and responsibility to their operations.

The authority of float glass manufacturers is further bolstered by rigorous industry standards and certifications that verify the quality and safety of their products. These standards underscore the precision and care inherent in every step of the process, providing customers with assurance backed by numbers and consistently verified excellence.

Ultimately, the float glass manufacturing process is a testament to human ingenuity, reflecting a deep reservoir of experience and expertise. Its intricate dance of temperature and timing, material and method, speaks to the authoritative position float glass holds in numerous industries worldwide. Trust in its quality is not a leap of faith but a calculated assurance, one that sees the invisible hand of expertise transform raw materials into transparent perfection. As this remarkable journey continues to evolve, the trust it inspires remains unwavering, solid as the glass it produces.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu