The float glass manufacturing process is a profound innovation that revolutionized the glass industry, offering a seamless method for producing high-quality glass with unparalleled precision. This article delves into the specifics of the process, showcasing its unmatched efficiency and drawing from industry expertise to offer a comprehensive guide for those interested in the next generation of glass manufacturing.

At the heart of the float glass manufacturing process is the raw materials selection and preparation. The primary components include silica sand, soda ash, and limestone, each playing a crucial role in ensuring the final product’s durability and clarity. These materials are meticulously weighed and mixed to form a batch that guarantees consistency in the glass produced.

The transformation begins in the furnace, a marvel of modern engineering that can reach temperatures exceeding 1,700 degrees Celsius. Here, the raw materials are melted to create a molten glass mixture. It’s an intricate balance of temperature and time, requiring close monitoring by skilled technicians to ensure the homogeneity of the glass, avoiding bubbles and impurities that could compromise quality.

Once the glass is in its molten state, it is gently fed onto a bath of molten tin.

This is where the “float” aspect of the process comes into play. The glass spreads out atop the tin’s surface, forming a perfectly even sheet due to the balance of gravity and surface tension. The tin bath is housed in a carefully controlled environment to prevent oxidation and ensure a pristine surface finish.

As the glass floats, it gradually cools, passing through a series of zones in a controlled environment chamber to prevent thermal shock. This annealing process is vital for relieving internal stresses, thus enhancing the structural integrity and ensuring the glass can be processed without risk of breakage during cutting or handling.

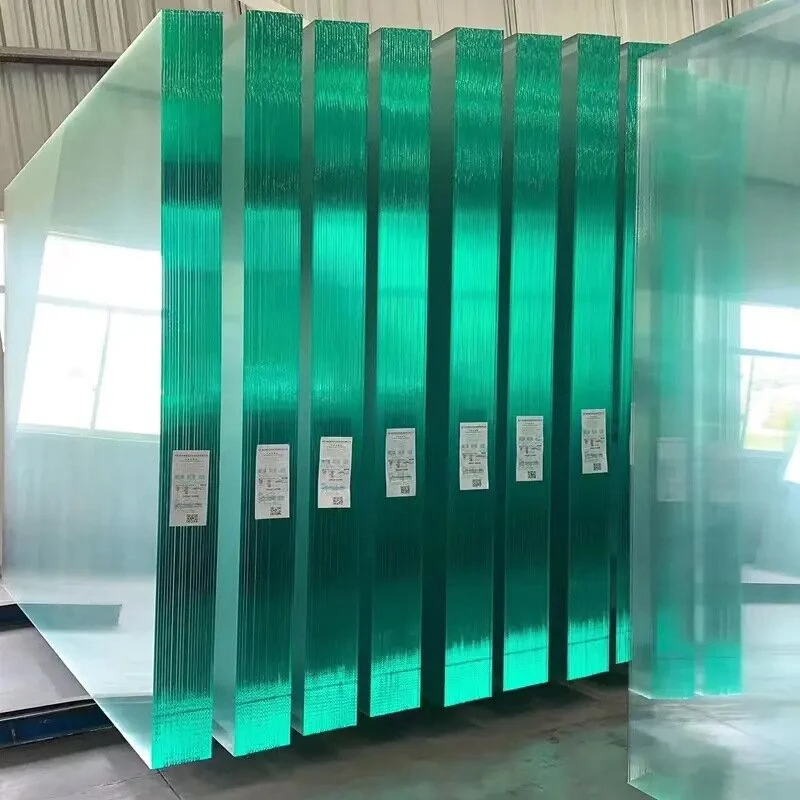

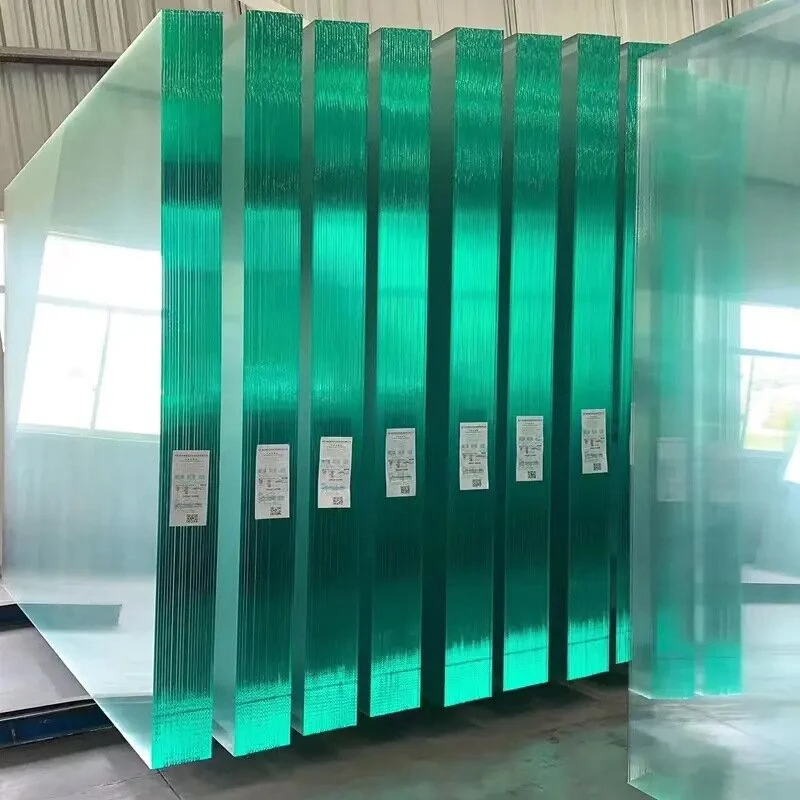

float glass manufacturing process

The cutting-edge precision of this process is a testament to the expertise embedded within the industry. Advanced conveyor belts and monitoring systems ensure that even the slightest deviations are corrected in real-time, maintaining the highest standard of product consistency. Highly sensitive cameras and sensors gauge the thickness, allowing adjustments that are measured in microns, a feat of engineering that underscores the expert knowledge driving this industry.

Beyond the technical parameters, the float glass manufacturing process is deeply trusted throughout various sectors due to its reliability and capability to meet diverse application needs. From architecture to automotive and electronics, float glass is revered for its clarity, strength, and versatility. Such attributes are not merely industry standards but a reflection of the deep authoritative advancements that have defined glass manufacturing.

Trust in the quality of float glass is fortified by rigorous testing and certification standards. Manufacturers adhere to strict international guidelines such as ISO 9001, ensuring every panel of glass meets structural and aesthetic expectations before reaching the consumer. Transparency in these processes and adherence to environmental standards also enhance the credibility and trustworthiness of manufacturers committed to sustainability.

In conclusion, the float glass manufacturing process stands as a paragon of modern manufacturing ingenuity, embodying the principles of Experience, Expertise, Authoritativeness, and Trustworthiness. Its ability to consistently produce glass of unmatched quality is a result of decades of refinement and dedication to technological advancement. For those seeking a deeper understanding of product quality and manufacturing excellence, the float glass process remains the quintessence of industrial success.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu