The Float Glass Manufacturing Process

Float glass, also known as flat glass, is one of the most common types of glass used in construction, automotive, and various industrial applications. The manufacturing process of float glass is a remarkable interplay of science and engineering, resulting in a product that is both aesthetically pleasing and performance-oriented. This article delves into the intricacies of the float glass manufacturing process, highlighting its key stages and innovations.

The float glass manufacturing process begins with the careful selection of raw materials

. The primary ingredients include silica sand, soda ash, and limestone, which are combined in a furnace at high temperatures exceeding 1,600 degrees Celsius (about 2,912 degrees Fahrenheit). Other materials, such as alumina, magnesium oxide, and various additives, may be included to enhance specific properties of the final glass product.

Once the raw materials are thoroughly mixed and melted, the molten glass is poured onto a surface of molten tin in a controlled environment. This step is crucial, as the tin acts as a medium that enables the glass to float and form a perfectly flat surface without the formation of bubbles or irregularities. The genius of the float glass method lies in the chemistry of the materials and the physics of fluid dynamics. The molten glass spreads out, forming a continuous ribbon of glass that is uniform in thickness.

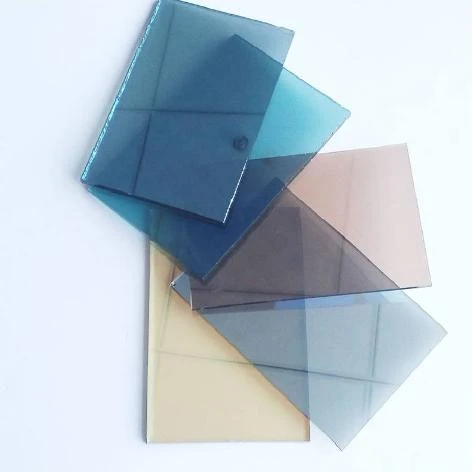

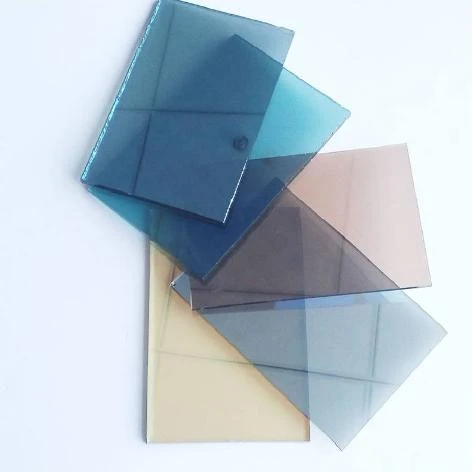

float glass manufacturing process

As the glass ribbon moves along the float line, it undergoes a cooling process known as annealing. It is passed through a series of controlled heating and cooling zones in a lehr (a type of oven) to relieve internal stresses. This step is vital to ensure the durability and strength of the glass. The thickness of the glass can be controlled by adjusting the speed at which it moves along the float line.

After the cooling process, the continuous ribbon of glass is cut into sheets of desired dimensions. The cut sheets then go through a quality control process where they are inspected for defects, such as bubbles, waves, or scratches. Any subpar glass is discarded to maintain high standards.

In recent years, advancements in technology have optimized the float glass manufacturing process. Automation and computerized systems improve precision and reduce human error. Environmentally friendly practices, such as recycling cullet (recycled glass), are increasingly integrated into the process, reducing waste and energy consumption.

In conclusion, the float glass manufacturing process is a sophisticated blend of high-temperature technology, material science, and engineering precision. The ability to produce large sheets of flat glass with consistent quality and minimal defects has revolutionized the glass industry. As technology continues to evolve, the float glass process will undoubtedly become even more efficient, sustainable, and innovative.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu