Float glass, a revolutionary leap in the field of glass manufacturing, continues to shape industries with its unique properties and multifaceted applications. This article delves into the depths of float glass, unraveling its meaning and exploring why it remains a staple material for both architectural and automotive sectors.

Float glass, derived from the innovative floating technique developed in the 1950s by Sir Alastair Pilkington, is a type of glass sheet produced by floating molten glass on a bed of molten tin. This method results in glass sheets that possess uniform thickness and exceptionally flat surfaces, qualities that are paramount for modern architectural and industrial applications.

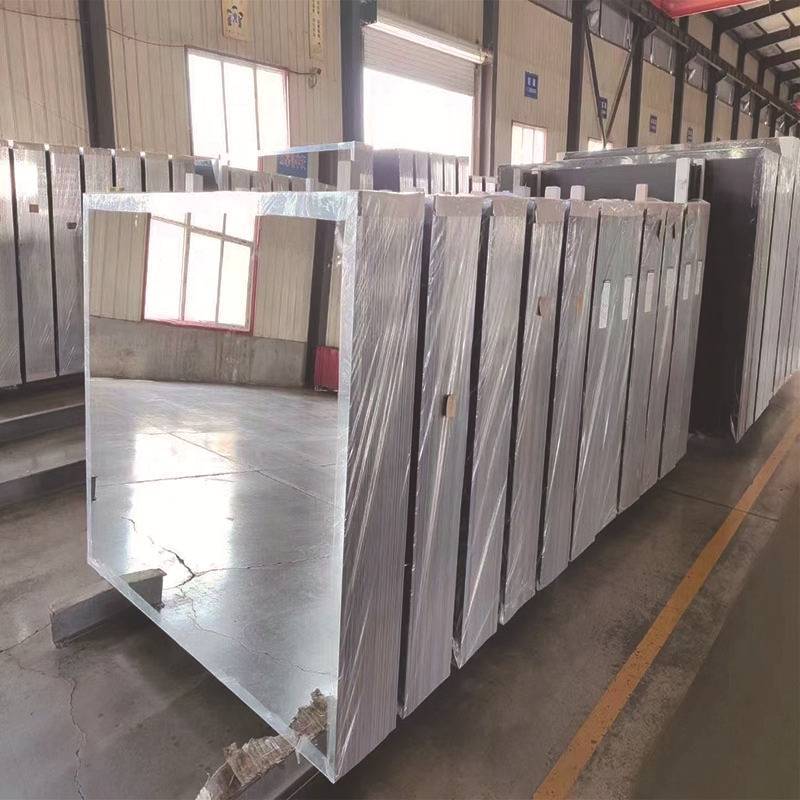

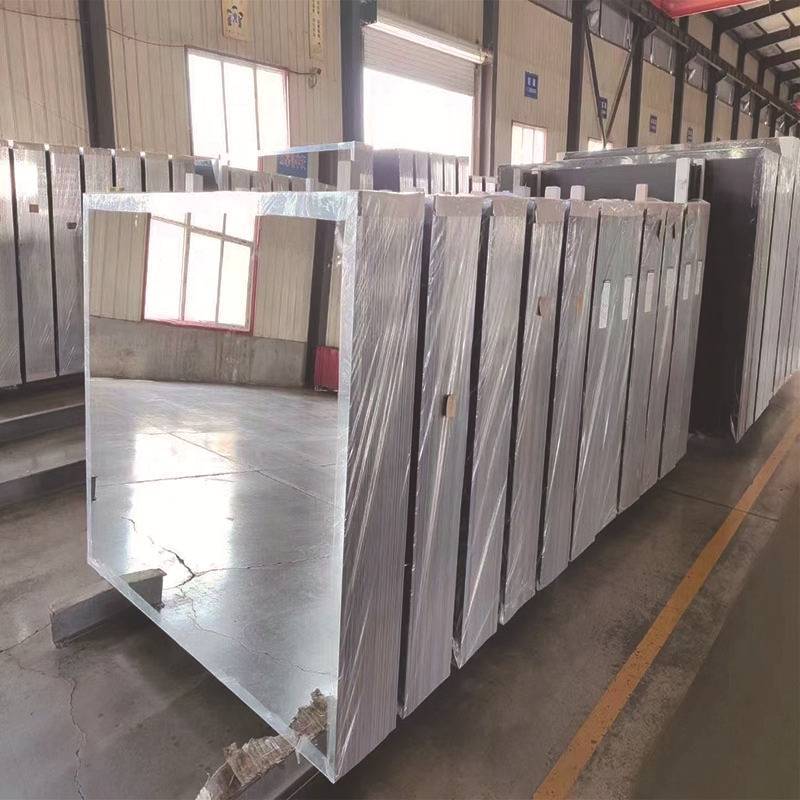

From an experiential perspective, float glass offers unparalleled clarity and smoothness, making it the material of choice for windows, facades, and display cases. Real-world usage underscores its importance; architects and designers consistently praise the way float glass enhances natural light flow, transforming spaces into hubs of aesthetic beauty and energy efficiency. Its versatility is further extended through its adaptability in being processed into laminated and tempered glass, thus enhancing safety standards while maintaining visual appeal.

In terms of expertise, the production of float glass requires meticulous control over the manufacturing environment. The process demands precise conditions where temperature and composition must be maintained to prevent distortions or inclusions. This precision positions float glass as a superior product in the market, reflecting the high level of skill and technical knowledge involved in its creation. Professional insights reveal that the float glass process not only improves the physical properties of the glass but also extends its durability, making it resistant to wear and environmental stress.

float glass meaning

The authoritativeness of float glass is emphasized by its ubiquitous use and the trust it commands across various industries. Global standards and certifications underscore its reputation; institutions and regulatory bodies recognize the reliability of float glass in meeting stringent safety and quality benchmarks. Its adoption across continents is a testament to its established integrity and performance consistency.

Trustworthiness is at the core of float glass's appeal. Manufacturers dedicate resources to continuous quality checks and innovations to assure clients of its efficacy. Many industrial case studies highlight float glass's role in large-scale projects, noting its consistency in performance and the trust clients place in it to meet their precise specifications. This trust is further solidified by the ongoing research and development efforts by industry leaders to enhance its features, such as reducing its carbon footprint and improving its thermal insulation properties.

In conclusion, float glass is more than just a material; it is a cornerstone of modern construction and design. Its development and sustained evolution reflect a deep understanding of materials science and a commitment to quality and environmental sustainability. For those seeking a reliable, high-performing glass product, float glass undoubtedly offers an unmatched combination of beauty, durability, and practicality, substantiating its position as a preferred choice in the global market.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu