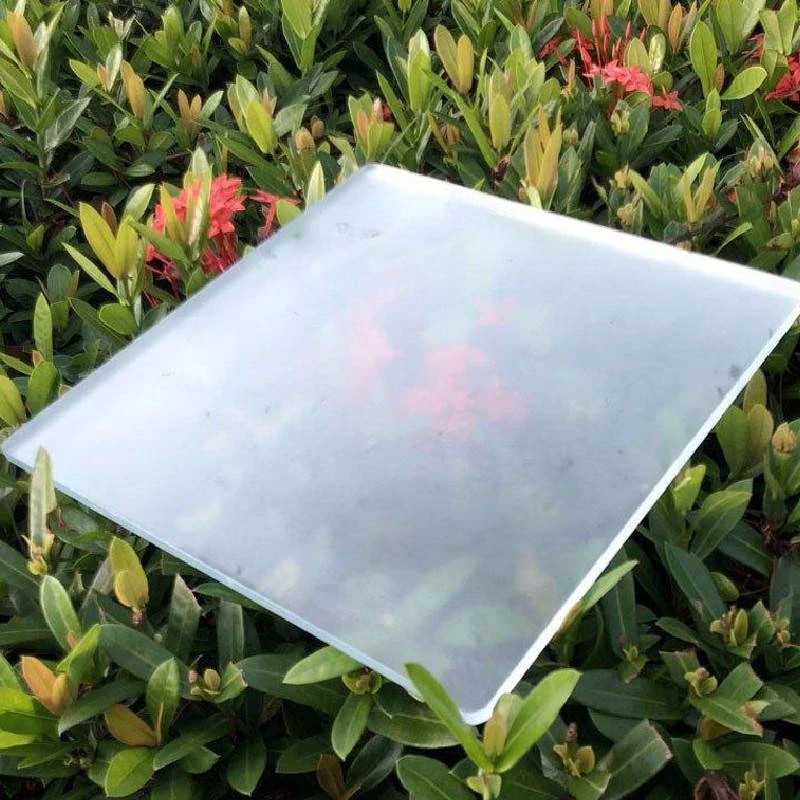

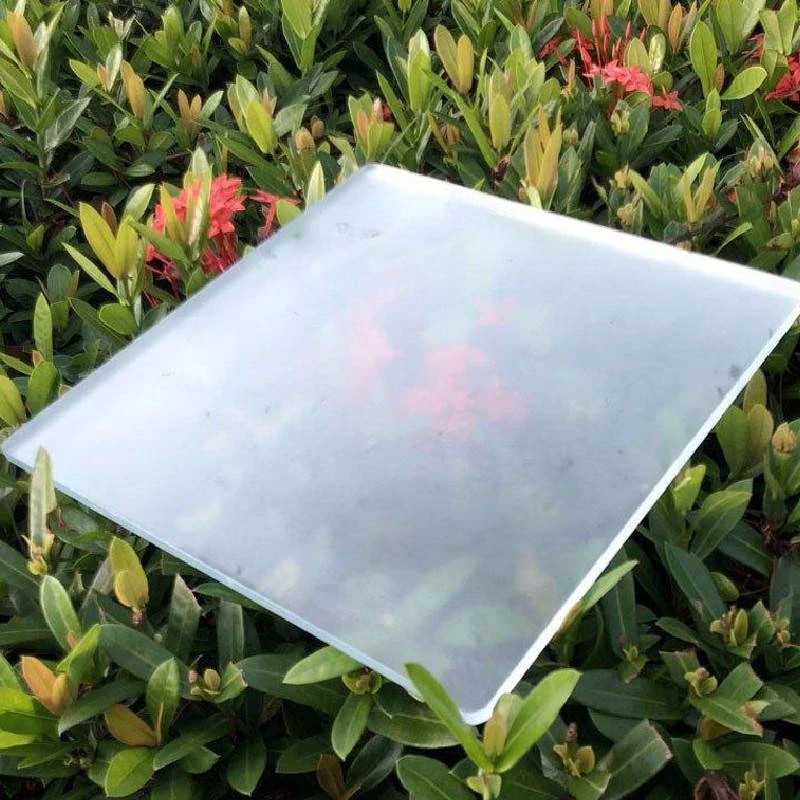

Float glass, an integral component frequently used across diverse industries, owes its widespread application to a groundbreaking manufacturing process developed in the mid-20th century. This process revolutionized glass production by making it possible to produce large sheets of clear, distortion-free glass with consistent thickness. As a professional who has delved deep into the glass industry, I will explore the distinct aspects of float glass that make it unparalleled in its utility and demand.

The float glass manufacturing process begins with raw materials such as silica sand, soda ash, limestone, and other chemicals that are melted at extremely high temperatures. This molten glass is then floated over a bed of molten tin, resulting in a perfectly flat, uniform surface on both sides. This method enables precision and efficiency, establishing a standard of clarity and consistency that was previously unattainable.

From an expertise standpoint, float glass is prized for its optical clarity and resistance to environmental factors, making it a preferred choice for construction, automotive, and various other industries. In architectural applications, float glass serves as a canvas upon which functionality and aesthetics can be beautifully balanced. Its adaptability in terms of size, thickness, and ability to undergo secondary processing such as tempering, laminating, and coating further enhances its applicability.

Professionals recognize float glass for its superior quality and performance. Its dimensional stability and robust nature offer noteworthy advantages in interior design and architecture, where natural light is controlled while maintaining thermal efficiency. Automotive manufacturers depend on float glass for its lightweight properties and its ability to be shaped into complex forms without losing integrity, ensuring passenger safety and comfort.

float glass meaning

The authority of float glass within the industry is further solidified by its environmental benefits. As sustainability and eco-friendliness become pivotal in manufacturing practices, float glass stands out due to its recyclability and energy efficiency. It plays a crucial role in the production of energy-efficient building solutions, such as double-glazed windows that reduce energy consumption by minimizing heat escape.

Trust in float glass is derived from decades of consistent and validated performance in rigorous environments. Its widespread use in critical infrastructure and transportation endorses its reliability. Consumers and industry experts alike value float glass for its non-toxic nature and its role in creating safe, modern environments, from homes to commercial spaces.

In conclusion, the impact of float glass extends beyond its physical properties. It represents a fusion of innovation, practicality, and visionary potential. For industries aiming to align with contemporary standards of efficiency, sustainability, and aesthetics, float glass remains an unmatched resource. Understanding its properties and production capabilities not only enhances its utilization but also contributes to the development of advanced applications, securing its place as a cornerstone of modern industrial processes.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu