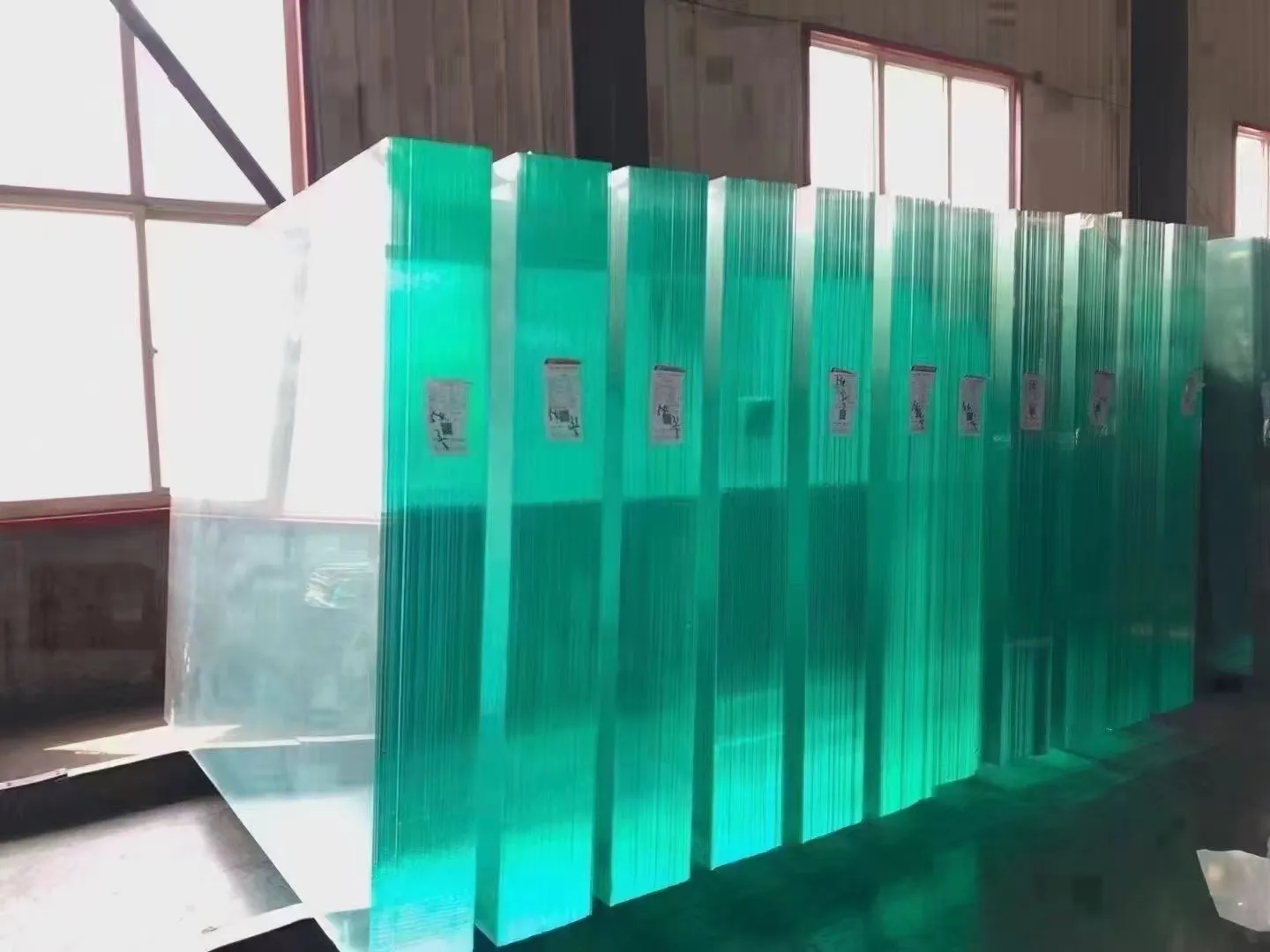

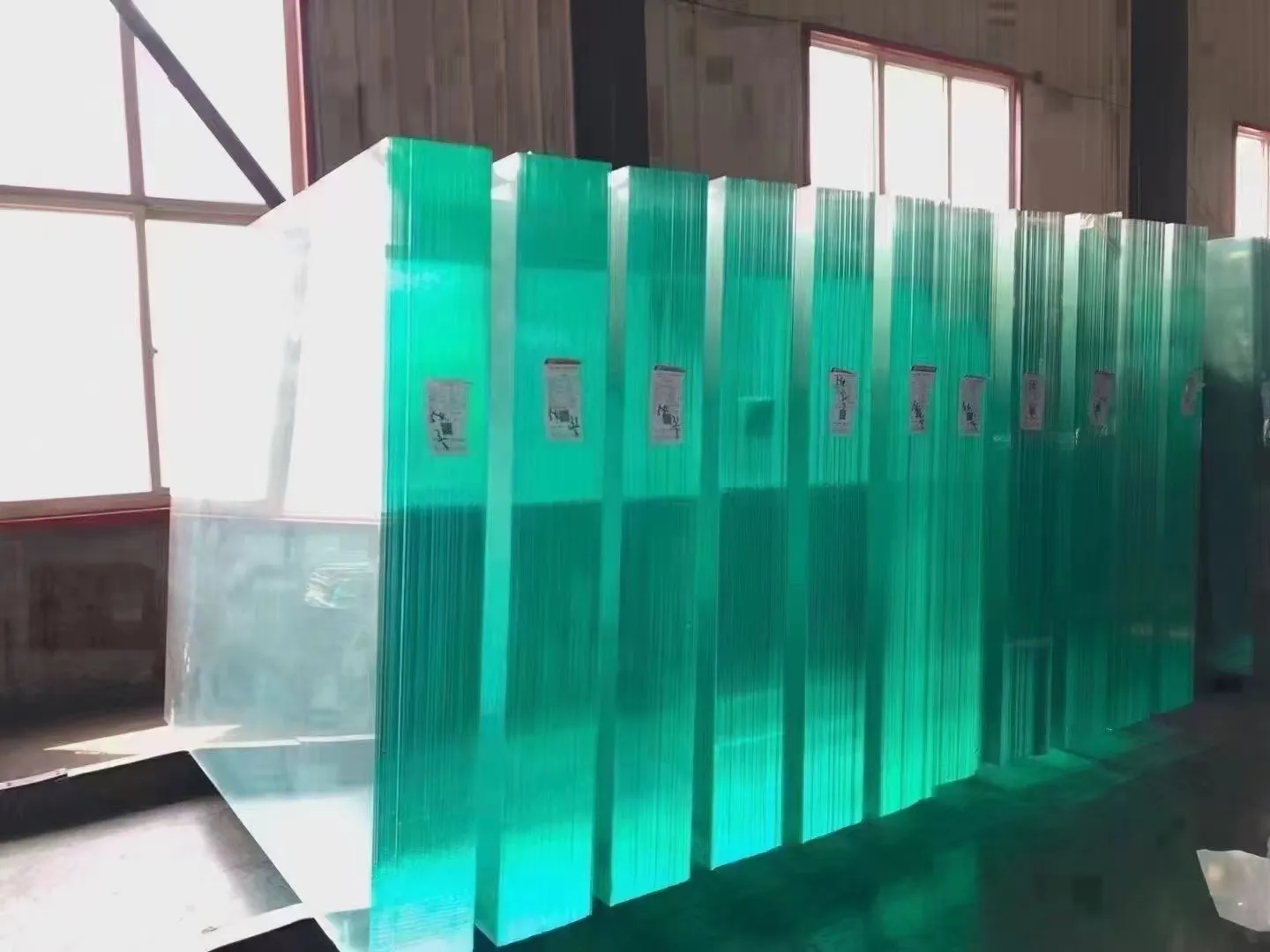

Float glass, a staple in the world of manufacturing and architecture, is a type of glass that is made by floating molten glass on a bed of molten metal, typically tin. This process results in a very smooth and flat surface, making it incredibly versatile and highly valued for a variety of applications around the globe.

The creation of float glass revolutionized the glass industry. Its origins trace back to Sir Alastair Pilkington in the mid-20th century, whose innovative approach replaced older methods that were less efficient and resulted in lower quality products. The float glass process involves mixing sand, soda ash, and limestone, melting these raw materials at high temperatures, and then allowing the molten glass to float over a bed of molten tin. This procedure ensures uniform thickness and a flawless surface, essential qualities for both aesthetic and practical applications.

One of the key advantages of float glass lies in its myriad of applications. In architecture, it serves as the foundational element for windows, facades, and glass doors. Its clarity and smoothness enhance natural light in a building, promoting energy efficiency and providing an expansive view of the outside world. Additionally, it can be easily customized through cutting, laminating, and coloring, allowing architects and designers to experiment with different styles and functionalities.

In the automotive industry, float glass’s strength and flexibility make it indispensable. Its ability to withstand extreme conditions and its safety properties, particularly when laminated, render it the perfect material for windshields and rear windows. The glass's ability to be tempered further enhances its durability, making it shatter-resistant and safer for passengers in the event of an accident.

float glass meaning

Moreover, float glass is also pivotal in the production of mirrors and extra-clear glass products. By applying reflective coatings, manufacturers can transform flat float glass into mirrors. Its inherent smoothness and distortion-free properties ensure high-quality reflections, which are essential in both residential and commercial settings. Extra-clear float glass, produced by reducing the iron content, offers an enhanced level of transparency and purity, making it ideal for display cases and premium furniture.

From a sustainability perspective, the float glass process is continuously evolving to reduce its environmental impact. Modern advancements have focused on minimizing energy consumption and utilizing recycled materials, thereby contributing to a circular economy. Improved furnace designs and the adoption of cleaner energy sources are steps taken by the industry to meet global sustainability goals.

For consumers and businesses, understanding the significance of float glass can influence purchasing decisions and project outcomes. Opting for float glass not only ensures superior quality and performance but also supports responsible production practices that are increasingly important in today's market.

In conclusion, float glass represents a remarkable blend of innovation, versatility, and sustainability. Its profound impact across various sectors demonstrates its integral role in modern manufacturing and design. With ongoing improvements in production techniques and a commitment to environmental responsibility, float glass remains a cornerstone of both present and future advancements in the glass industry.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu