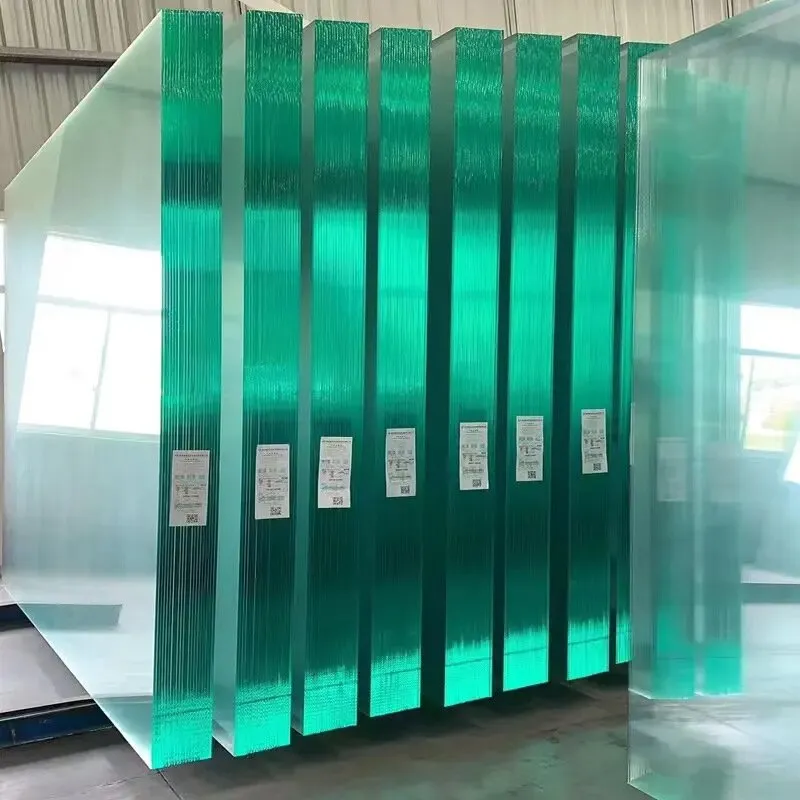

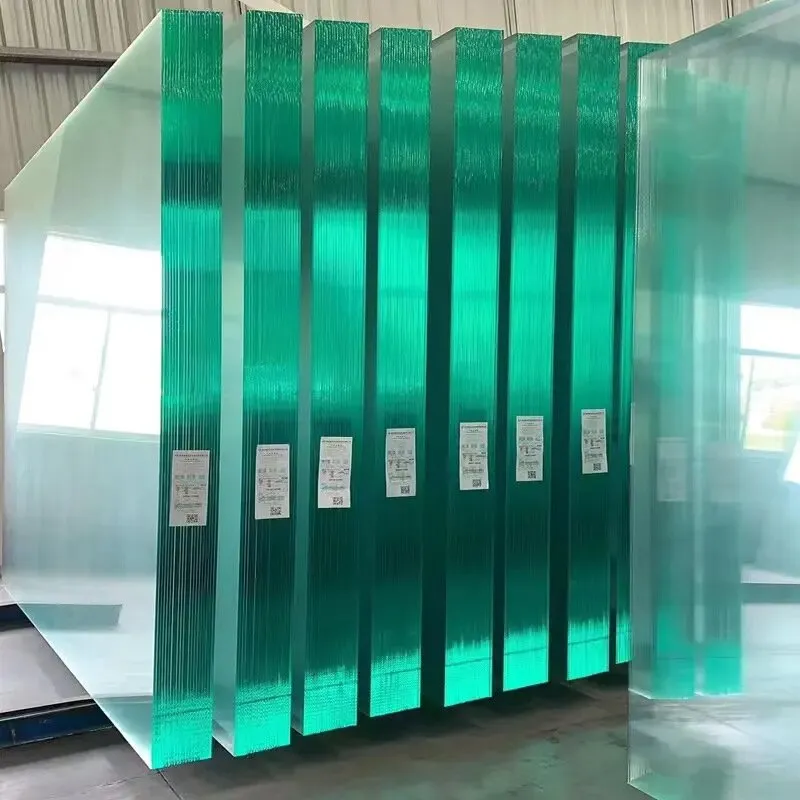

Float glass, a staple in modern industrial production, represents a revolution in the way we manufacture glass products. An integral part of everyday life, float glass constitutes the basis of windows, mirrors, and countless other transparent structures around us. Its ubiquity has cemented its position in both widespread consumer goods and specialized, high-performance applications.

Float glass production involves a meticulously controlled process that ensures uniform thickness and flawless surfaces, distinguishing it from other glass types. The process begins with raw materials like silica sand, soda ash, and limestone, which are melted in a furnace at approximately 1700 degrees Celsius. The molten glass is then poured onto a bath of molten tin in a highly-controlled atmosphere. This float method, pioneered in the 1950s by Sir Alastair Pilkington, results in a perfectly flat and clear sheet as the glass floats over the tin bath, cooling gradually to form a solid.

Industries that demand precision and reliability gravitate towards float glass due to its unique properties. Architects prefer it for its superior clarity and uninterrupted spans, allowing for stunning visual connectivity between indoor and outdoor environments. Additionally, its structural uniformity makes it an excellent substrate for complex coatings and laminations that enhance thermal insulation, reflection, and even self-cleaning attributes. Thus, float glass is not just transparent but adaptable, playing pivotal roles in energy-efficient building designs.

The versatility of float glass extends beyond architecture. It is a crucial component in the automotive industry, providing the seamless, aerodynamic shapes essential for modern vehicles. In electronic devices, it serves as a substrate for displays and solar panels, emphasizing its reliability and adaptability in high-tech applications. The continuous advancements in float glass technology, such as thinner and stronger compositions, cater to these evolving demands, reflecting the material's robust innovation track.

float glass meaning

Environmentally, float glass manufacturing has made significant strides in reducing its carbon footprint. Recycling plays a vital role in this process. Reclaimed glass, or cullet, is incorporated into the production cycle, reducing the need for raw materials and energy consumption. This sustainable practice not only conserves resources but also enhances the glass's purity by lowering emission-related impurities during melting. Many producers are also embracing renewable energy sources to power their operations, further mitigating environmental impact while maintaining high production standards.

The industry demands not only technical excellence but also trust and credibility. Leading float glass manufacturers uphold strict quality control measures, adhering to international standards and certifications that assure clients of the product's durability and performance. Moreover, their commitment to research and development ambitions foster innovative solutions tailored to specific industry requirements, showcasing their authoritative stance in the materials science domain.

The future of float glass looks toward smart technologies and novel applications. Incorporating intelligent systems within glass panels, embedding sensors and digital interfaces, transforms static surfaces into interactive platforms, heralding a new era of smart buildings and IoT (Internet of Things) integration. Experts predict that these advancements will create safer, more efficient living and working environments, making float glass a pivotal material in technological progress.

In conclusion, float glass embodies the synthesis of tradition and innovation, ecological mindfulness, and technological prowess. It stands as a testament to human ingenuity, continuously reshaping the landscapes of architecture, automotive, and electronics. Whether as a transparent barrier or a technological interface, float glass offers unparalleled expertise and reliability, underscoring its position as a cornerstone in both conventional and cutting-edge applications. As industries evolve, so too will the capabilities of float glass, reflecting a dynamic balance between enduring quality and futuristic vision.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu