Unearthing the facets of float glass technologies can significantly enrich the comprehension of this paramount material within a plethora of industries. Float glass, a staple in the construction and automotive sectors, stems from its unique manufacturing process wherein molten glass is floated on a bed of molten tin, resulting in a uniform thickness and flatness. This methodology ensures superior optical clarity and surface smoothness, becoming a vanguard of modern glass production.

Professionals entrenched in architectural design and industrial development recognize float glass not merely for its pristine aesthetics but also for its adaptability and robustness. The reliability and durability of float glass, its anti-distortion quality, and its resistance to atmospheric conditions position it as an indispensable component in sustainable building practices. More importantly, float glass's recycling potential appeals to environmentally conscious manufacturers and consumers, endorsing its green credentials.

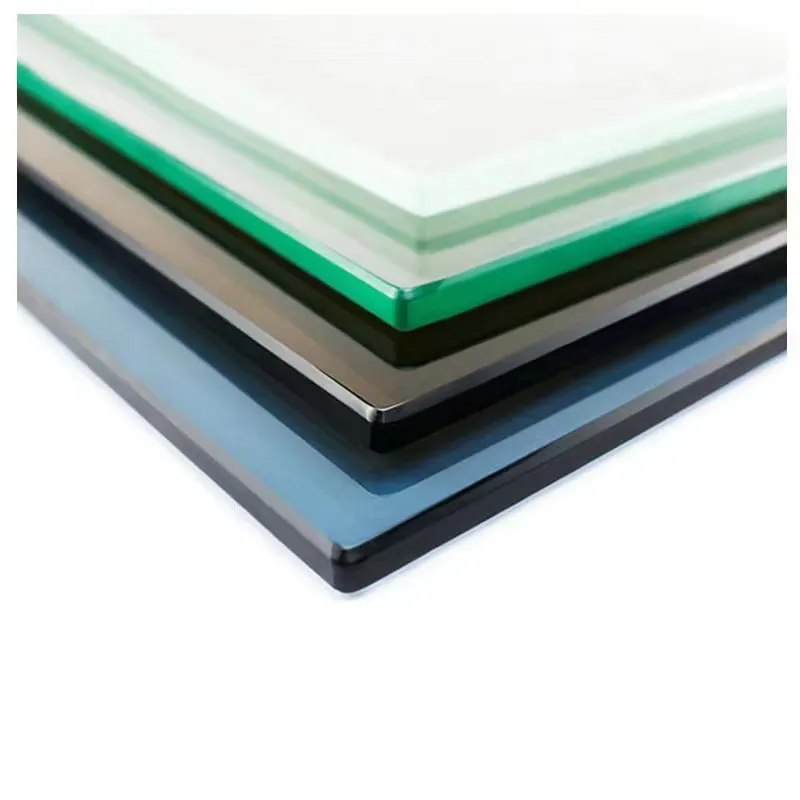

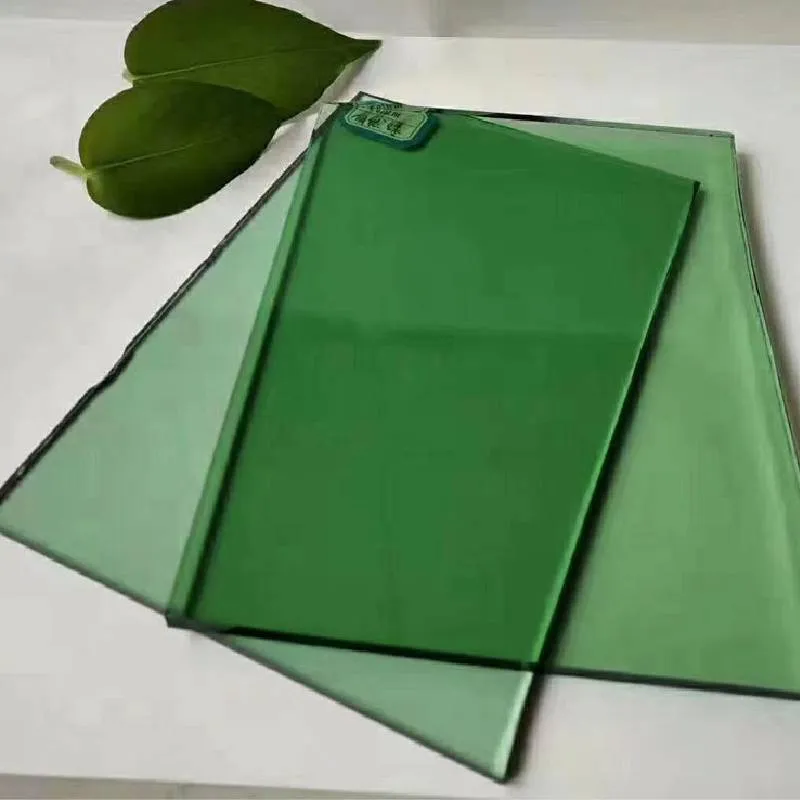

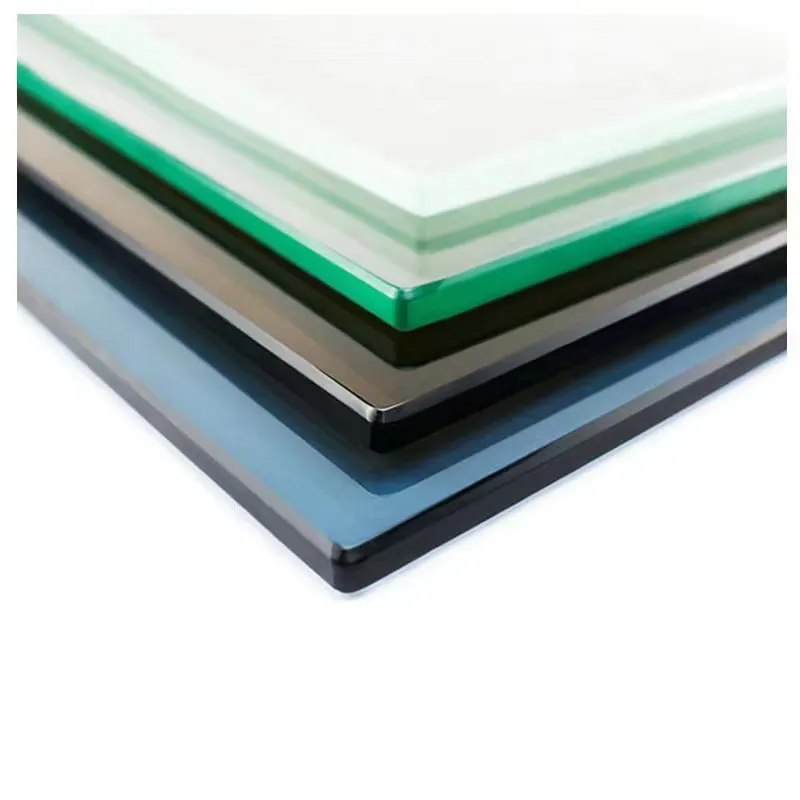

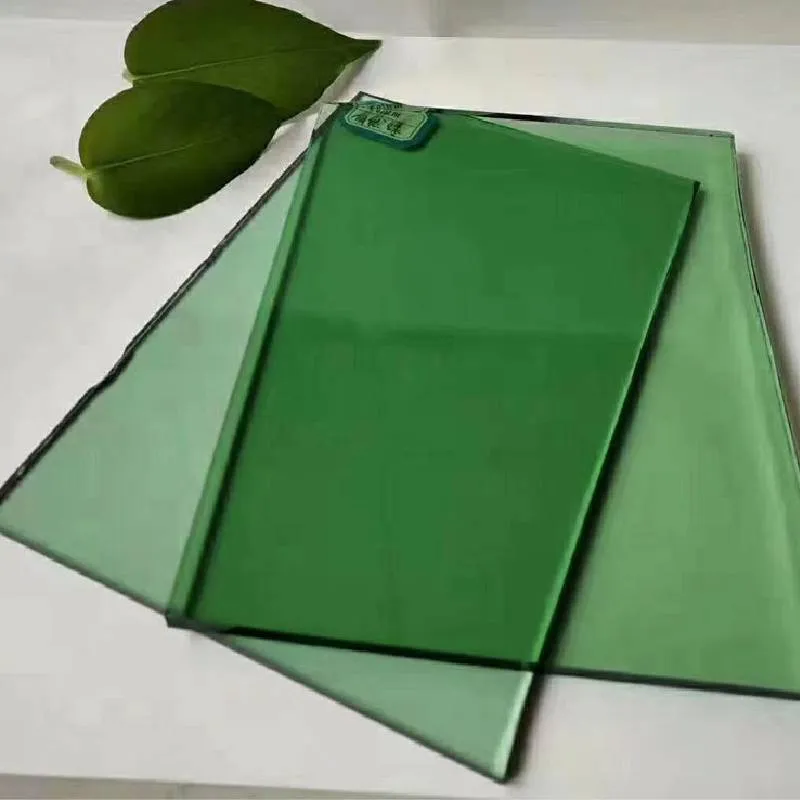

In-depth experience shared by fabrication specialists highlights that tailored modifications, such as lamination, tempering, or coating, can morph standard float glass into a tailored solution addressing specific client needs—be it for thermal insulation, soundproofing, or enhanced security measures. Understanding these adaptations allows businesses to provide bespoke options designed to satisfied heightened customer demands.

Moreover, expertise in the scientific and technological innovation surrounding float glass ensures continual advancements. Cutting-edge anti-reflective coatings are a prime example, developed to meet the needs of high-precision optical instruments and solar panel efficiency. Continuous research assures that floated glass evolves, embodying advancements that lead to improved performance, efficiency, and application expansiveness.

float glass pdf

Authoritativeness in the dialogue surrounding float glass is affirmed by renowned research institutes and multinational corporations continually pushing the boundaries of glass technology.

These entities lend credibility to the assertions associated with float glass applications and innovations. Through concerted efforts in research, greater emphasis is placed on developing sustainable production methods and integrating smart technologies, thereby fortifying the status of float glass within its various spheres of application.

The trustworthiness associated with float glass is a direct corollary of both its historical reliability and the stringent quality controls observed during its manufacturing processes. As stakeholders ranging from manufacturers to end-users demand higher degrees of transparency in product quality, robust standards and certifications, such as ISO and CE marks, provide assurance of float glass's dependable performance.

In summary, the profound impact of float glass on numerous facets of modern infrastructural and technological developments is irrefutable. The continuous advocacy for environmentally friendly processes, coupled with steadfast improvements in float glass technology, paints a promising future. As the desire for multifunctional and aesthetically pleasing glass solutions grows, both industry newcomers and veterans can express confidence in the adaptability, resilience, and ecological viabilities that float glass reliably offers.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu