Understanding Float Glass Plates Their Composition, Properties, and Applications

Float glass plates are widely recognized in the glass manufacturing industry for their exceptional clarity and uniform thickness. Produced through the float glass process, these plates have become indispensable in various applications ranging from architecture and automotive industries to electronics and art. This article delves into the composition, properties, and diverse applications of float glass plates.

What is Float Glass?

Float glass is made by floating molten glass on top of molten tin, a method developed in the 1950s by Sir Alastair Pilkington. This innovative technique allows for the creation of flat glass with minimal distortion and surface imperfections. The term float describes the process in which the glass floats on the tin, resulting in a perfectly smooth surface. Once the glass cools down and solidifies, it can be cut into plates of various sizes.

Composition of Float Glass Plates

Float glass plates are primarily composed of silica (SiO2), which is the main ingredient of glass. In addition, the formulation includes soda (Na2O) and limestone (CaCO3), which lower the melting point of silica and stabilize the glass structure. Minor additives such as alumina, magnesium oxide, and various metal oxides are included to enhance specific properties like durability, thermal resistance, and color. The precise formulation can vary depending on the intended application of the glass.

Key Properties of Float Glass Plates

1. Clarity and Transparency One of the most remarkable characteristics of float glass is its outstanding clarity. This quality makes it ideal for applications where transparency is crucial, such as windows, mirrors, and display cases.

2. Uniform Thickness The float glass process yields plates with uniform thickness, an essential requirement for many applications, including architectural uses and in the manufacturing of lenses and optical devices.

3. Chemical Resistance Float glass is resistant to various chemicals, making it suitable for use in laboratories and industries where exposure to substances could occur.

4. Thermal Stability Float glass can withstand a range of temperatures. However, it is important to note that specific types of float glass have varying thermal resistance capabilities, which can be further enhanced through processes like heat treatment or lamination.

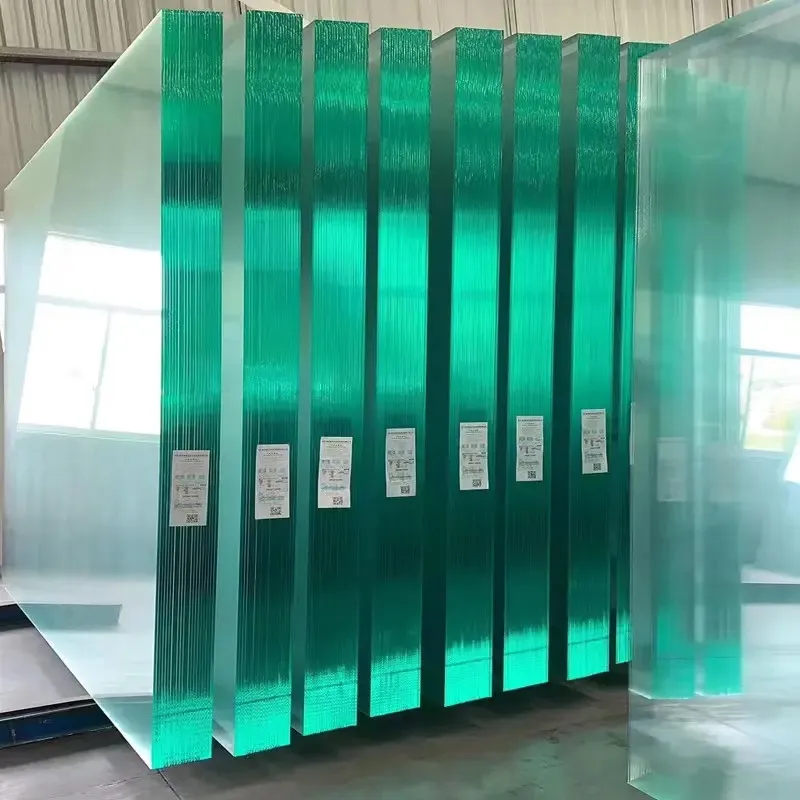

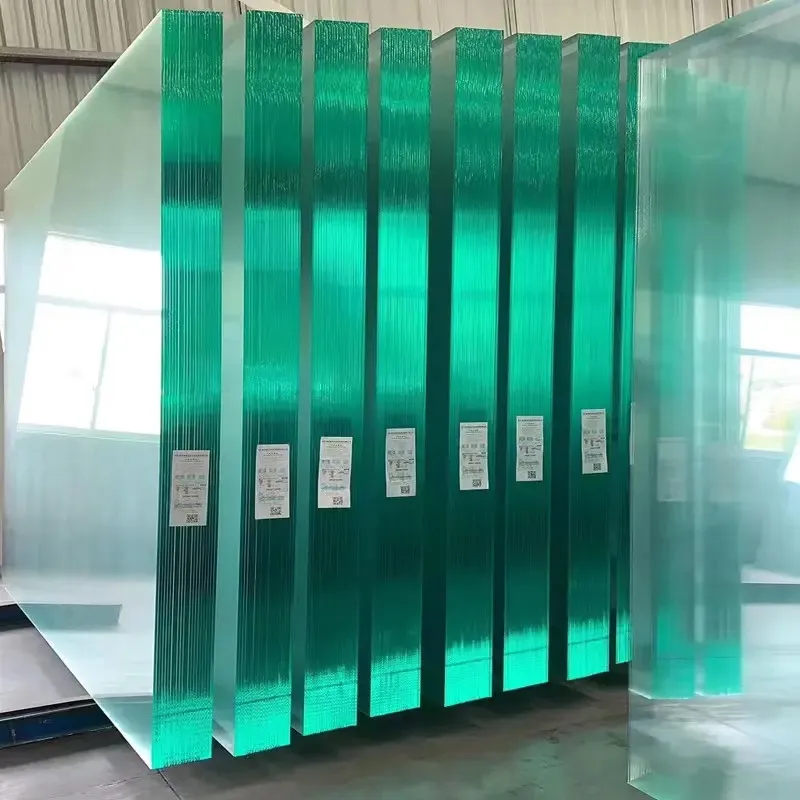

float glass plate

5. Reflective Properties Depending on the composition, float glass can exhibit reflective qualities, making it popular for mirrors and other reflective surfaces.

Applications of Float Glass Plates

Float glass plates find extensive applications across different industries

1. Architectural Applications Float glass is predominantly used for windows, facades, and storefronts in buildings. Its clarity and aesthetic appeal allow architects to design spaces that maximally utilize natural light while providing visibility to the outside.

2. Automotive Industry Car windows and windshields often utilize float glass plates because of their optical clarity and strength. Safety glass variants, such as laminated or tempered float glass, are essential for passenger safety.

3. Electronics The electronics industry uses float glass in the production of screens for televisions, monitors, and smartphones. The flatness and clarity of the glass are critical in ensuring visual quality and device performance.

4. Interior Design and Art Float glass plates are also used in decorative applications, such as table tops, art installations, and museum displays. Their aesthetic qualities help highlight artworks while providing durability and protection.

5. Solar Energy Float glass is vital for solar panels, where its transparency allows sunlight to penetrate effectively while protecting the photovoltaic cells beneath.

Conclusion

Float glass plates are an exemplary innovation in the glass industry, offering a remarkable combination of clarity, uniformity, and durability. Their versatile applications across various sectors demonstrate their significance in modern life, from enhancing architectural designs to contributing to technological advancements in electronics and renewable energy. As advancements in glass technology continue, float glass plates will likely evolve further, paving the way for new possibilities and applications.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu