The float glass process has transformed the manufacturing landscape, particularly within the architectural and automotive industries, where precision and flawless surface quality are paramount. This method, which accounts for the production of approximately 90% of the world’s flat glass, involves floating molten glass on a bed of molten tin, ensuring consistent thickness and smooth surfaces. Here is an exploration of the float glass process, examining its expertise, reliability, and the experiential benefits it yields to businesses and consumers alike.

Precision and Perfection The Unsung Heroes of Float Glass

At the heart of the float glass process is an unparalleled level of precision. By pouring molten glass at a temperature of around 1000°C onto a pool of molten tin, the material naturally spreads and solidifies into a uniform sheet with perfectly flat surfaces, thanks to the even viscosity and pressure distribution. This rigorous process eradicates any possibility of imperfections typically found in traditionally manufactured glass, such as warps and inconsistencies, lending itself to applications demanding clarity and uniformity.

Expertise in Glass Manufacturing

From an industrial and technical standpoint, the float glass process epitomizes expertise in engineering and materials science. Manufacturers employ cutting-edge technology to maintain optimal conditions within the glass bath, precision-controlled cooling tunnels, and stringent quality checks. Renowned institutions and corporations have contributed extensively to refining these processes, ensuring that the glass produced meets stringent safety and performance standards. The expertise applied to the float glass process is reflected in its use in high-performance vehicles and structurally demanding architectural endeavors.

Authoritative Impacts in Various Industries

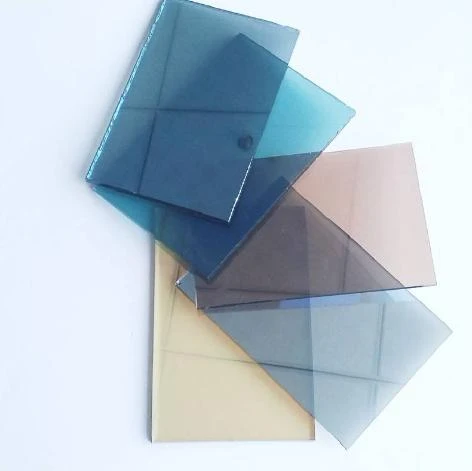

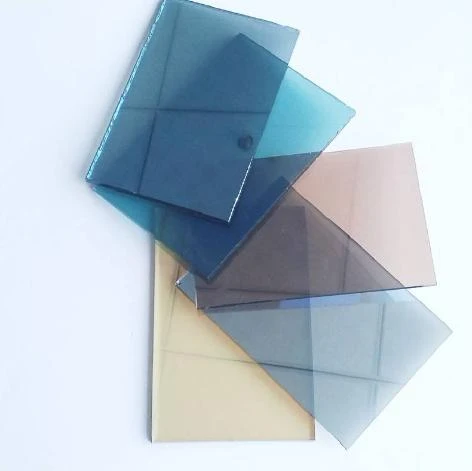

float glass process

The authoritative prowess of float glass can be observed in its critical role in modern architecture and automotive designs. Its ability to be tailored via further processes – such as tempering, laminating, and coating – extends its functionalities to include energy efficiency, increased strength, and enhanced safety features. The adoption of float glass in skyscrapers exemplifies the industry's trust in its unparalleled transparency and robustness. In automotive industries, manufactures rely on this glass for its resilience and optical clarity, ensuring driver safety and aesthetic appeal.

Trustworthiness of Float Glass in Consumer Applications

Consumers' trust in products utilizing float glass stems from its proven track record of performance and safety. This type of glass accounts for nearly all the windows in commercial and residential buildings, signifying its trustworthiness and the confidence industries place in its reliability. Enhanced variants of float glass, such as solar control glass and acoustic glass, further exhibit its versatility in meeting contemporary consumer demands. This trust is built on decades of consistent product delivery and satisfaction.

Conclusion The Sustainable Edge

One cannot overlook the environmental consciousness that the float glass process supports. The ability to recycle glass perpetually without any degradation in quality underlines its sustainability. Manufacturers are progressively integrating eco-friendly practices, like reducing energy consumption and minimizing emissions during production, aligning with global initiatives for a greener future.

In summary, the float glass process has not only established itself as an industry cornerstone but also continues to inspire innovation in material application. Through precision engineering and a commitment to superior quality, it stands as a testament to human ingenuity, offering industries and consumers alike a product they can rely on for its performance, safety, and sustainable attributes.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu