As the backbone of modern architectural and automotive industries, the float glass process stands as a testament to innovation and engineering excellence. The evolution of this technique has marked a turning point in glass manufacturing, pushing the boundaries of quality and efficiency in creating seamless flat glass. This method not only defines high standards for clarity and structural integrity but also supports the global glass industry's demand with remarkable flexibility and precision.

Originating from the visionary minds of Sir Alastair Pilkington and Kenneth Bickerstaff in the 1950s, the float glass process transformed glass production by introducing a continuously flowing process. This innovation eliminated the need for grinding and polishing, which were time-consuming and could compromise the integrity of the slab. By contrast, the float glass method uses carefully controlled conditions to create perfectly smooth glass surfaces that meet rigorous standards for modern construction and automotive industries.

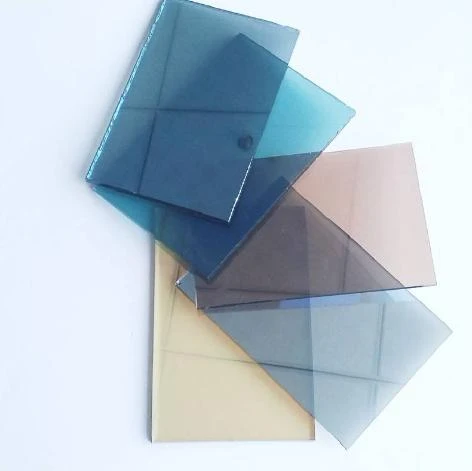

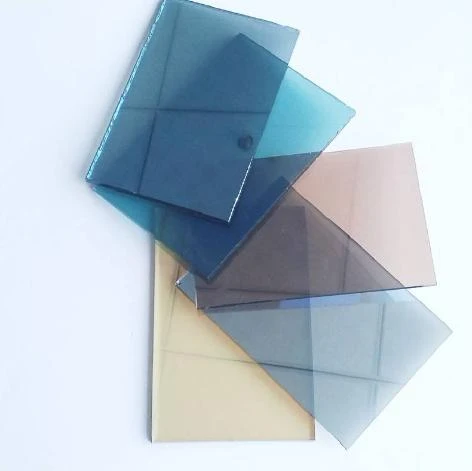

The process itself is an intricate dance of molten materials and advanced technologies. Primarily, it begins with a mixture of silica sand, soda ash, dolomite, and lime, which are melted in a furnace at approximately 1700°C. This molten glass is transported from the furnace and floated onto a bath of molten tin under carefully controlled atmospheric conditions. The unique properties of tin, being denser than molten glass yet non-reactive, allow the glass to spread evenly across the surface, creating a uniform thickness and unparalleled smoothness.

Expertise in managing the float glass process involves precise control over several variables, including temperature gradients and gas atmospheres, to prevent imperfections such as waves or ripples. The glass ribbon is slowly cooled and annealed in a controlled environment to relieve internal stresses, ensuring optimal strength and resistance to thermal shock—a critical feature for both architectural windows and automotive glass.

float glass process

A hallmark of authority in the float glass sector lies in the commitment to sustainability and innovation, as industry leaders continuously seek to enhance the efficiency and environmental impact of their operations. Modern float glass plants are at the forefront of incorporating renewable energy sources, utilizing waste heat recovery systems, and minimizing emissions through sophisticated filtration technologies and improved furnace designs. These efforts not only decrease the industry's carbon footprint but also reinforce the trustworthiness of float glass manufacturers as stewards of responsible production.

Trust in the float glass product results from rigorous quality assurance processes and adherence to international standards such as the ISO 9001. Each pane of glass undergoes meticulous inspection, during and after production, using automated and manual methods to identify and rectify any anomalies. This dedication to quality ensures that the final product meets the high expectations of discerning customers in various applications, from skyscrapers to high-speed trains.

In conclusion, the float glass process has redefined the glass manufacturing industry with its commitment to precision, innovative advancement, and environmental stewardship. Its role is indispensable in producing the high-quality, flawless glass needed in today’s world, making it a cornerstone of modern infrastructure. For anyone engaged in architectural design or automotive manufacturing, understanding the nuances and capabilities of float glass offers a pathway to not only meet but exceed expectations for quality and sustainability. This blend of technical mastery and strategic foresight solidifies the float glass process as an authoritative, reliable choice in an ever-evolving marketplace.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu