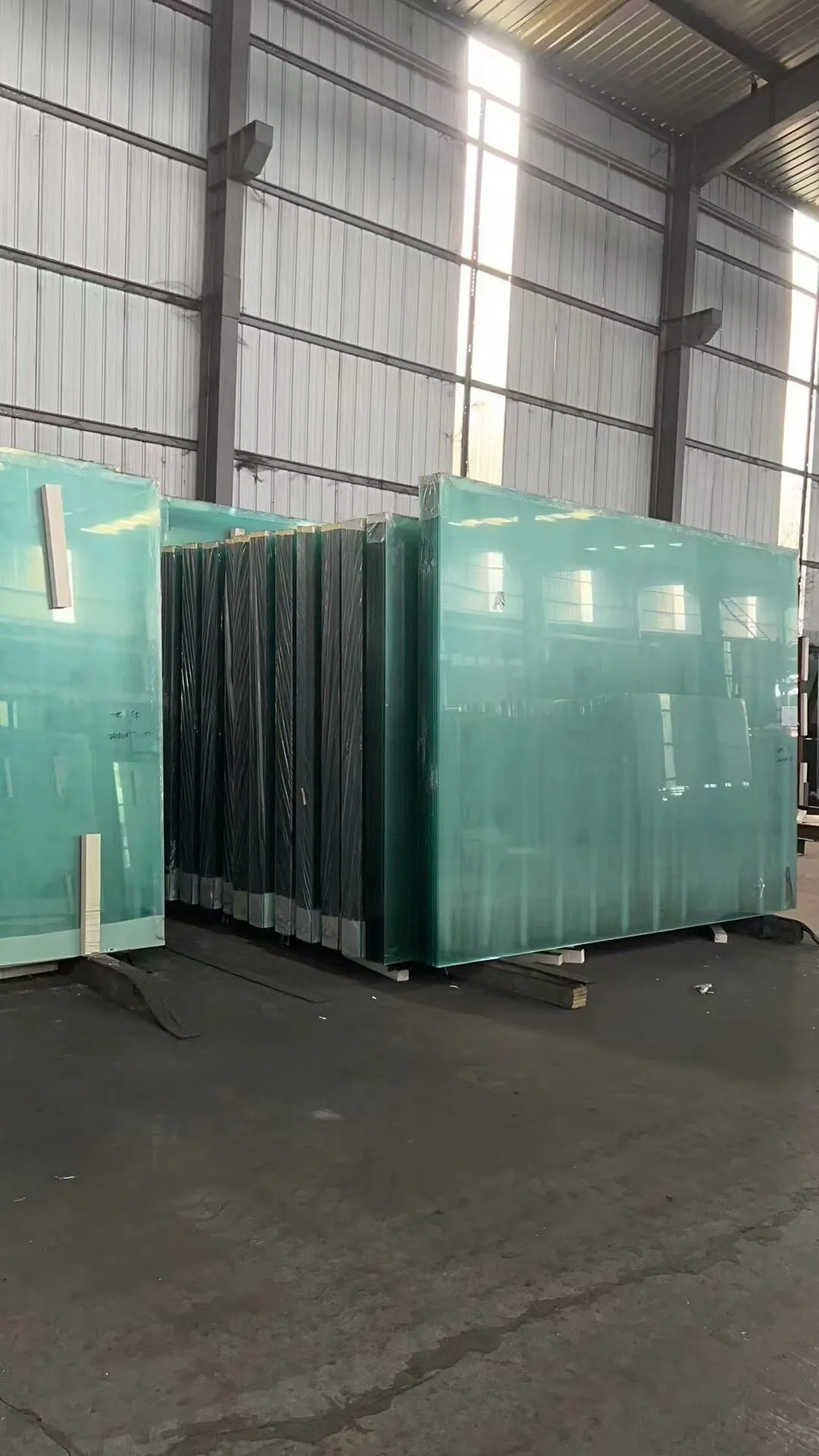

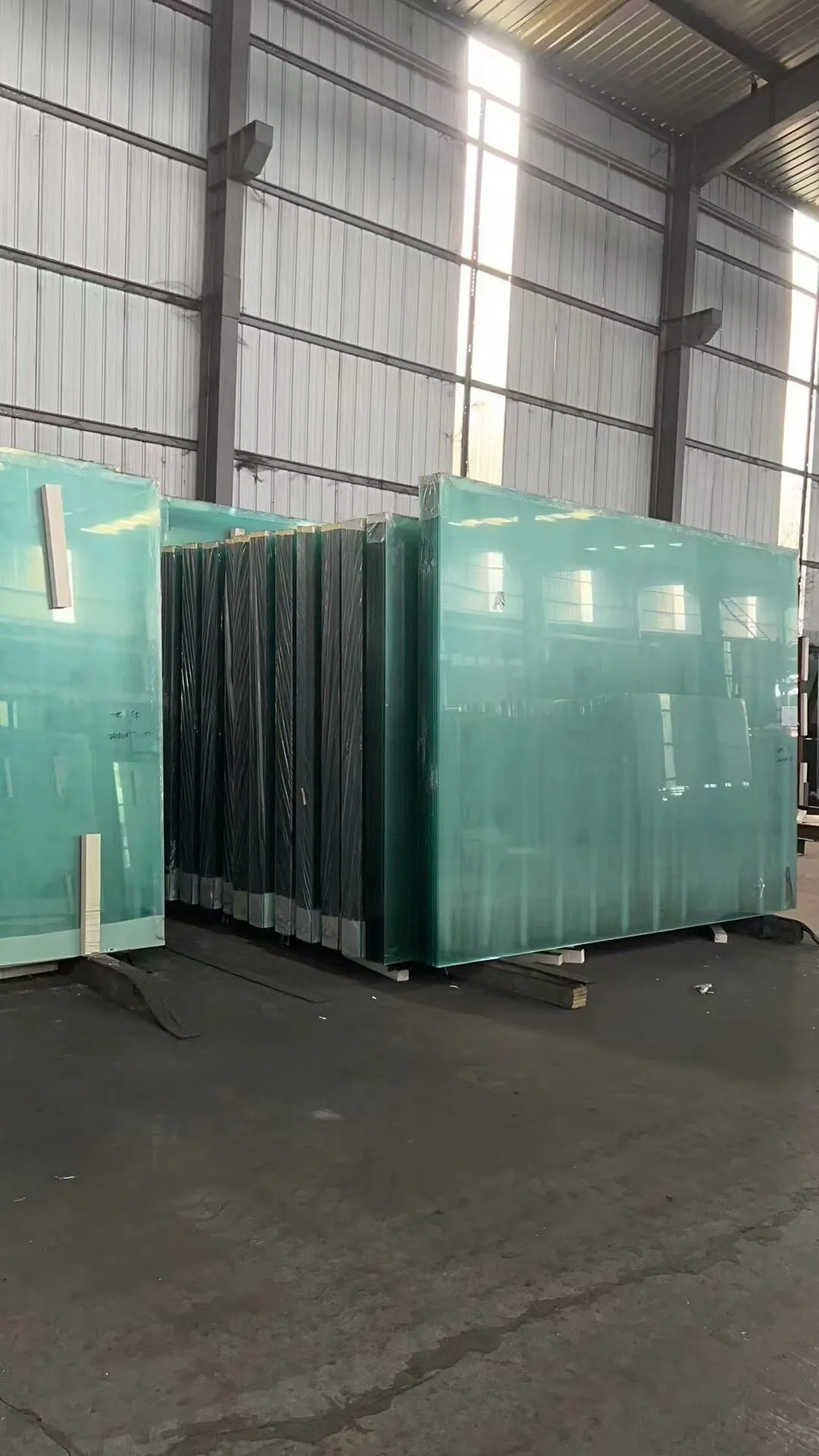

The float glass process revolutionized the way we produce high-quality glass, and its impact is ubiquitous in our everyday lives, from sleek skyscraper façades to the gleaming displays of smartphones. This method, first introduced in the mid-20th century, remains the gold standard for manufacturing flat glass due to its efficiency and precision.

Mastering the float glass process starts with its fundamental components sand, soda ash, and limestone. These raw materials are carefully mixed and melted at approximately 1700°C in a furnace, creating a molten glass pool. Floating this mixture on a bed of molten tin gives birth to its name—the float glass process. The glass spreads out over the molten tin surface, turning seamlessly flat due to gravity and surface tension, resulting in a uniformly finished product that requires minimal further processing.

One of the most notable attributes of the float glass process is its unparalleled consistency in thickness and surface uniformity, hallmarks of its superior quality. This precision is vital for applications requiring optical clarity and perfection, such as solar panels, vehicle windows, and architectural structures. The process's ability to maintain precise thickness, typically ranging from 2mm to 25mm, caters to a wide array of industrial needs.

Experts in the field of glass manufacturing highlight the float glass process’s adaptability. By altering the furnace parameters and adding specific metal oxides, manufacturers can produce a variety of glass products, including tinted or tempered glass, to meet diverse industrial specifications. This versatility not only optimizes production but also paves the path for innovation in specialty glass products.

float glass process

An authoritative voice in the float glass sector, Pilkington, a pioneer of this technology, provides a wealth of expertise and continually advances the process. Their innovations in coated glass technologies, such as self-cleaning and solar control glass, underscore their commitment to sustainable solutions, further bolstering the ecological footprint of float glass manufacturing.

Trust is paramount in any industrial process, and the float glass process is no exception. Rigorous quality control standards are foundational,

ensuring that each sheet of glass meets precise international specifications. Manufacturers employ advanced non-contact measurement systems and autonomous inspection methods to guarantee defect-free glass production and uphold their commitment to excellence, mitigating any potential risks and enhancing reliability.

In conclusion, the float glass process is more than just a transformative manufacturing technique; it represents a blueprint of modern industry standards—sustainability, adaptability, and precision. Its continued evolution and development are testaments to the enduring collaboration between scientific innovation and practical application. By understanding and leveraging the intricacies of this process, industries not only enhance product quality but also build trust and authority in their respective markets.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu