Float Glass Sharpening System Revolutionizing Glass Fabrication

The float glass industry has seen tremendous advancements in technology over recent years, and one of the most significant innovations is the float glass sharpening system. This sophisticated technology not only enhances the precision of glass cutting but also optimizes efficiency, reducing waste and operational costs.

The float glass process involves creating a smooth and flat surface by floating molten glass on top of molten tin. While this method yields high-quality glass sheets, the edges often require finishing to ensure safety and improve aesthetics. Traditionally, this edging process involved manual techniques and basic machinery, which could lead to inconsistencies and high labor costs.

The introduction of automated float glass sharpening systems has transformed this aspect of glass fabrication. These systems use advanced CNC (Computer Numerical Control) technology to precisely shape and polish glass edges, allowing for intricate designs and clean finishes that meet the highest standards in the industry. By minimizing human error and ensuring uniformity, manufacturers can produce glass products that are both visually appealing and safe for use in various applications.

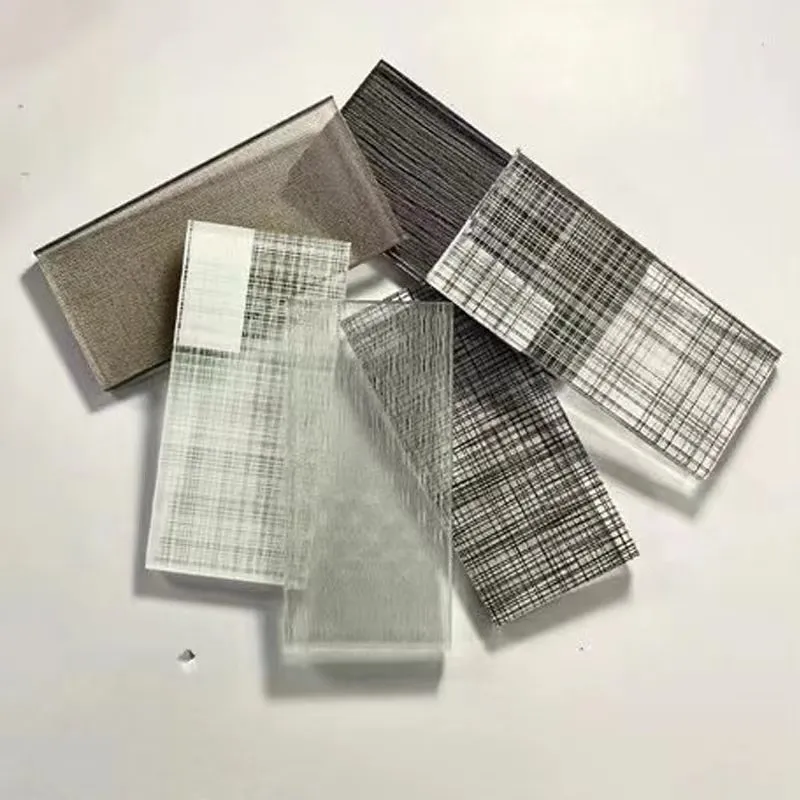

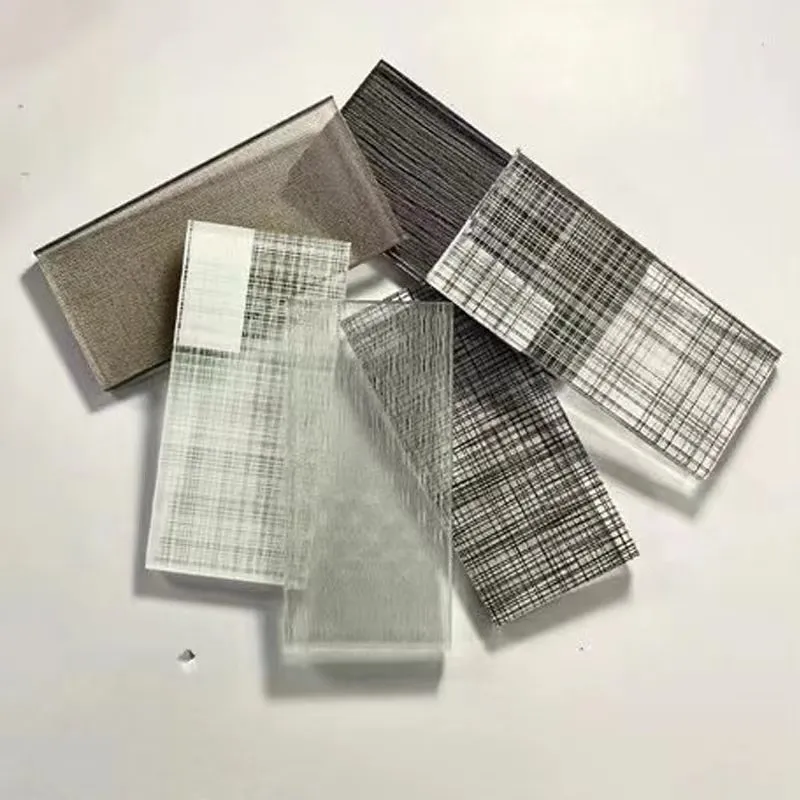

float glass sharpening system

One of the primary advantages of float glass sharpening systems is their speed. These machines can operate continuously, significantly increasing production rates compared to manual methods. This efficiency translates to shorter lead times for customers, allowing manufacturers to respond more rapidly to market demands. Moreover, the automation of the sharpening process frees up skilled labor for more complex tasks, thus improving overall productivity.

In addition to efficiency, these systems also contribute to sustainability efforts within the industry. By optimizing the sharpening process, material waste is minimized, effectively reducing the environmental footprint of glass production. Manufacturers can also recycle glass more efficiently due to the consistent quality of the edges produced, facilitating the circular economy in glass manufacturing.

The float glass sharpening system embodies the future of glass fabrication. With its ability to enhance precision, efficiency, and sustainability, it represents a significant leap forward in technology that not only benefits manufacturers but also contributes to higher-quality products for consumers. As the demand for glass continues to grow across various sectors—including architecture, automotive, and renewable energy—the importance of such advanced systems cannot be overstated. The ongoing evolution in float glass sharpening technology promises even greater innovations on the horizon, paving the way for a brighter future in glass manufacturing.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu