Exploring Float Glass Sheets An Essential Component of Modern Architecture and Design

Float glass, commonly referred to as float glass sheets, represents a significant advancement in glass manufacturing that has transformed architectural design and construction. The process of creating float glass dates back to the mid-20th century and has since become the standard for producing high-quality flat glass used in a variety of applications. This article delves into the characteristics, production process, applications, and benefits of float glass sheets, highlighting their significance in contemporary design.

What is Float Glass?

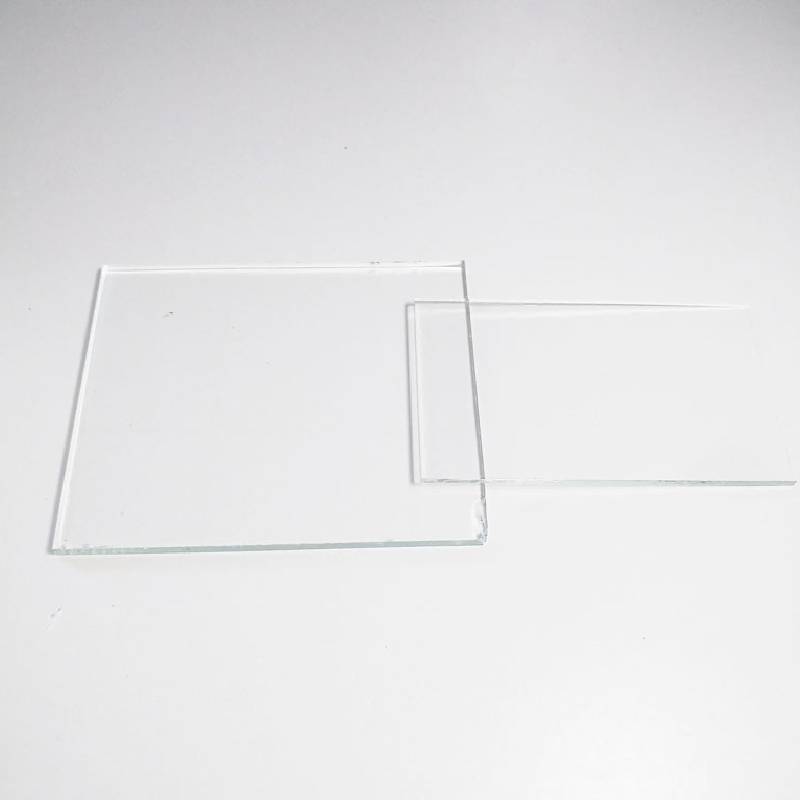

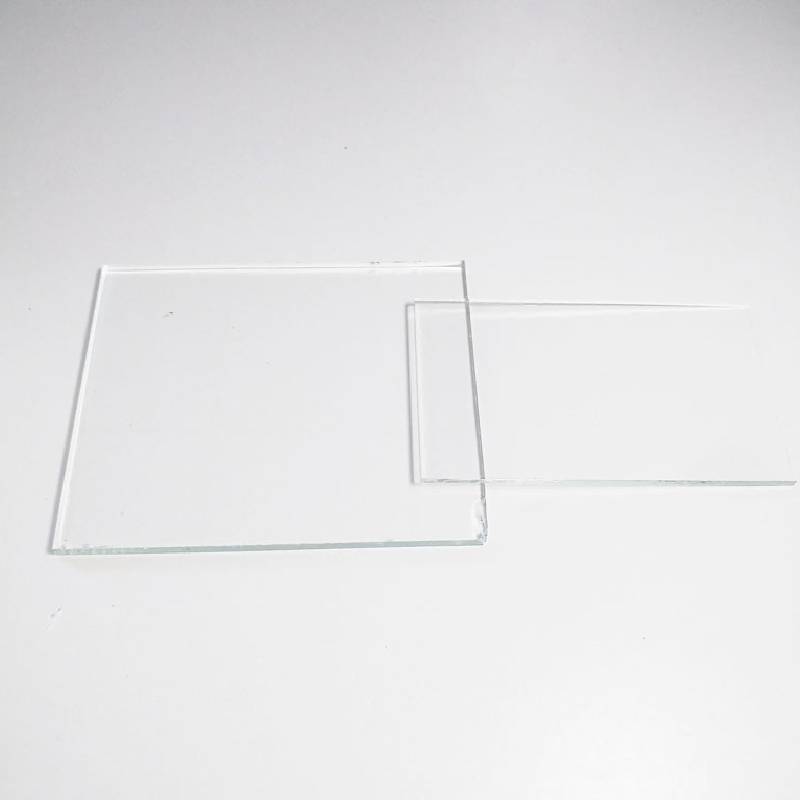

Float glass is a type of flat glass created using a unique method where molten glass is floated on top of molten tin. This process results in a smooth, uniform thickness with exceptional clarity and transparency. The term float signifies the way the glass floats on the tin, allowing it to spread evenly and create blemish-free surfaces. The result is a highly polished sheet of glass that is ideal for both aesthetic and functional uses.

The Production Process

The production of float glass involves several steps

1. Raw Materials The primary components of float glass are silica sand, soda ash, and limestone, along with other additives to enhance properties such as durability and resistance to ultraviolet (UV) radiation.

2. Melting The raw materials are mixed and melted in a furnace at high temperatures, typically exceeding 1,700 degrees Celsius. This process results in a molten glass mass.

3. Floating The molten glass is carefully poured onto a bath of molten tin, where it spreads out evenly. The density difference between the glass and tin allows the glass to float, forming a smooth surface.

4. Annealing After floating, the glass moves through an annealing lehr, where it is gradually cooled. This process relieves internal stresses, ensuring the glass is strong and stable.

5. Cutting and Packaging The final product is then cut into sheets of various sizes and packaged for distribution.

Applications of Float Glass Sheets

Float glass sheets are widely used across various industries and applications

float glass sheets

1. Construction and Architecture Float glass is primarily used in residential and commercial buildings. Its clarity and aesthetic appeal make it ideal for windows, facades, and glass doors.

2. Automotive Industry The automotive sector extensively employs float glass for windshields and windows due to its toughness and optical clarity.

3. Interior Design In interior applications, float glass is used in furniture, mirrors, and decorative elements. Its versatility allows designers to experiment with textures and finishes, enhancing the overall aesthetics of spaces.

4. Electronics Float glass is also utilized in the manufacturing of screens for televisions and smartphones, providing a durable yet visually appealing surface.

Benefits of Float Glass Sheets

Float glass sheets come with numerous advantages that make them a preferred choice in various applications

1. Optical Clarity The smooth surface and uniform thickness of float glass provide exceptional clarity and light transmission, crucial for applications requiring visibility.

2. Durability Float glass is highly resistant to scratches and impact, making it a durable choice for high-traffic areas.

3. Customization Float glass can be easily cut, shaped, and treated with various coatings to enhance properties like energy efficiency and UV resistance.

4. Sustainability The glass is recyclable and can be reused without compromising quality, making it an environmentally friendly option.

5. Safety Features Float glass can be treated or laminated to enhance safety, making it suitable for areas prone to breaking, such as schools and public buildings.

Conclusion

Float glass sheets are an integral part of modern design and construction, offering unmatched qualities that cater to diverse needs. From enhancing architectural aesthetics to maintaining safety and delivering durability, float glass continues to be a transformative material in our built environment. As technology advances, we can expect further innovations in the production and application of float glass, underscoring its importance in both current and future designs.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu