Understanding Float Glass Types An In-Depth Look

Float glass, a fundamental material in the construction and manufacturing industries, is crucial for a variety of applications ranging from architectural design to industrial processes. It is characterized by its smooth, flat surface and unparalleled clarity, achieved through a unique manufacturing process that involves floating molten glass on molten tin. This article delves into the types of float glass, their properties, and applications.

The Manufacturing Process

Before discussing the various types of float glass, it is essential to understand the manufacturing process. Float glass is produced by pouring molten glass onto a bed of molten tin. This method allows the glass to spread evenly and form a flat sheet as it cools. The result is a product that is consistent in thickness and free of distortions. Once cooled, the glass is cut into sheets of standard sizes and can be further processed or treated based on the requirements of its intended use.

Types of Float Glass

1. Annealed Float Glass

This is the standard type of float glass produced without any additional treatment. It undergoes a controlled cooling process that ensures its stability and uniform thickness. Annealed float glass is widely used in windows and doors due to its clarity and affordability.

2. Tempered Float Glass

Tempered glass is treated with heat to increase its strength. It’s approximately five times stronger than standard float glass. When broken, it shatters into small, blunt pieces rather than sharp shards, making it a safer option for applications in areas where human impact is a concern, such as in shower doors, glass tables, and facades of buildings.

3. Laminated Float Glass

This type of float glass consists of two or more layers of glass bonded together with a layer of polyvinyl butyral (PVB) in between. This construction enhances safety and sound insulation. Laminated glass remains intact even when shattered, making it ideal for skylights, glass doors, and windows in high-security areas.

float glass types

4. Low-E Float Glass

Low emissivity (Low-E) glass has a special coating that reflects heat while allowing sunlight to pass through. This feature makes it energy efficient, helping to maintain indoor temperatures and reducing heating and cooling costs. It is widely used in residential and commercial buildings, especially in energy-efficient systems.

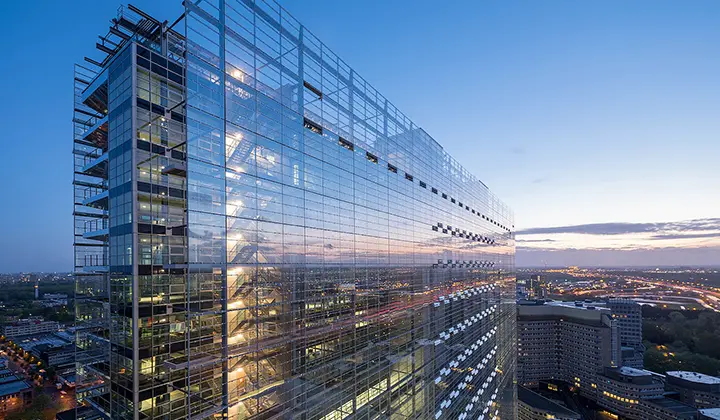

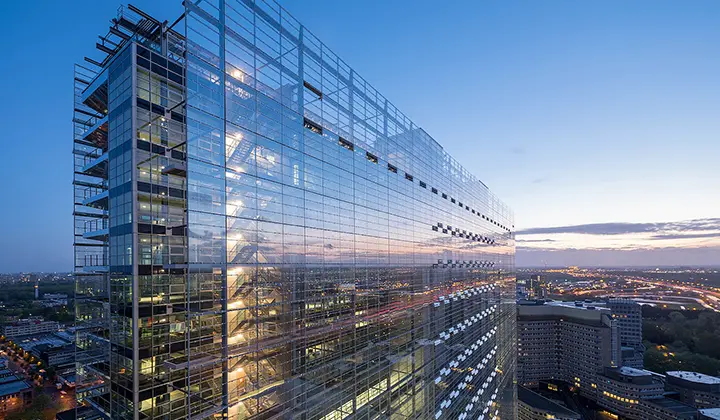

5. Reflective Float Glass

Reflective glass is coated with a thin layer of metal oxides, which gives it a mirror-like finish. This type of glass is used in commercial buildings, as it can reduce solar heat gain and enhance privacy while providing aesthetic appeal. It also helps to diminish glare and control light ingress.

6. Tinted Float Glass

Tinted float glass has pigments added during the manufacturing process to reduce glare and control solar heat transmission. It comes in various colors, providing not only functionality but also visual appeal. Tinted glass is often used in commercial buildings, automotive glazing, and residential applications.

Applications of Float Glass

The versatility of float glass allows it to be utilized in numerous applications. It is a primary material in the construction industry, being used in windows, doors, curtain walls, and partitioning systems. Furthermore, float glass finds extensive use in interior design for mirrors and tabletops, as well as in the automotive industry for windshields and side windows.

Innovative applications are continuously being developed thanks to advancements in glass technology. Smart glass, for instance, can change its properties in response to environmental conditions, providing dynamic solutions for energy efficiency and user comfort.

Conclusion

Float glass is an indispensable material characterized by its clarity, strength, and versatility. With various types available, including annealed, tempered, laminated, low-E, reflective, and tinted float glass, each serves distinct purposes across multiple industries. As technology advances, the glass industry will continue to evolve, introducing more innovative solutions that cater to both functional and aesthetic needs in our built environment. Whether for residential, commercial, or industrial use, understanding float glass types helps in choosing the right material for any project.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu