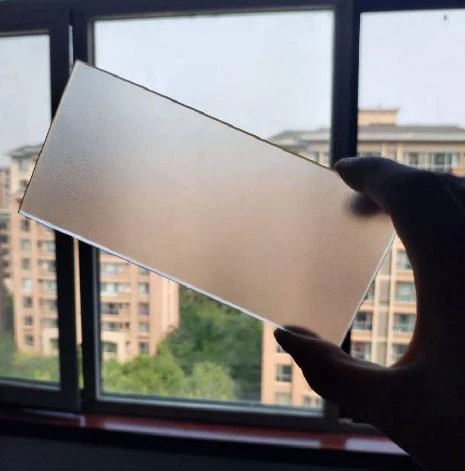

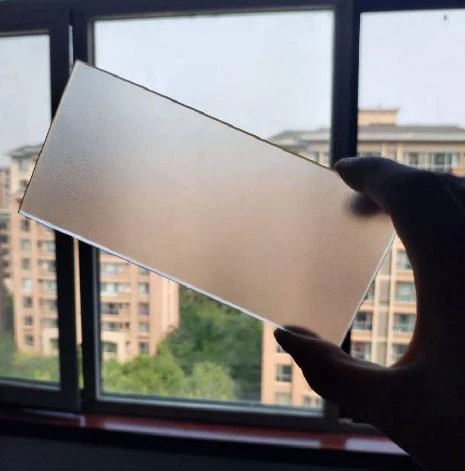

Float Glass Versatile Applications and Benefits

Float glass is a type of glass that is widely used in various industries and everyday applications due to its remarkable clarity, high quality, and durability. The production of float glass involves a unique process in which molten glass is floated on a bed of molten tin, creating an even and smooth surface. This method ensures that the glass is flat and free from distortions or impurities, making it ideal for numerous applications.

One of the primary uses of float glass is in the construction industry. It is extensively employed in the manufacture of windows, doors, and facades for buildings. The transparency and aesthetic appeal of float glass allow natural light to illuminated spaces while providing excellent insulation against weather elements. Moreover, float glass can be treated to enhance its thermal resistance, providing energy efficiency benefits by reducing heating and cooling costs.

Float Glass Versatile Applications and Benefits

Float glass also plays a crucial role in the automotive industry. It is used for manufacturing windows, windshields, and mirrors in vehicles. The glass is treated to withstand high-impact and temperature fluctuations, ensuring passenger safety and comfort. Innovations in float glass technology have led to the development of advanced features such as acoustic insulation and UV protection, contributing to a quieter and healthier inside environment for drivers and passengers alike.

float glass uses

Another significant application of float glass is in the production of interior decor. With its smooth finish and crystal-clear appearance, float glass is ideal for creating visually appealing products such as mirrors, table tops, and display cases. The versatility of float glass allows designers and manufacturers to craft various shapes and sizes, making it a popular choice in home furnishings and commercial displays. In addition, float glass can be decorated or treated with different coatings to enhance its aesthetic attributes or create specific finishes, adding to its appeal in interior design.

The electronics industry also benefits from float glass. It is used in the production of screens for televisions, smartphones, and other digital devices. The need for high-definition displays has driven demand for quality float glass, which offers superior image clarity and color representation. The capabilities for thinness and lightweight construction of float glass products align with the demands of modern technology, making it a key material in this rapidly evolving field.

Sustainability is another important aspect of float glass. As the world increasingly shifts toward environmentally friendly solutions, float glass manufacturers have embraced recycling and energy-efficient production methods. Float glass can be recycled indefinitely without loss of quality, making it a sustainable choice. Many producers incorporate recycled glass in their manufacturing process, reducing waste and conserving natural resources.

In summary, float glass plays a pivotal role in various sectors, from construction and automotive to interior design and electronics. Its superior properties, such as clarity, durability, and versatility, make it a preferred material across different applications. As technology evolves and the demand for sustainable practices increases, the importance of float glass continues to grow. Whether enhancing architectural beauty, ensuring automotive safety, or bringing functionality to electronic devices, float glass remains an indispensable material in our daily lives and modern economy.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu