What is Aluminum Mirror Glass?

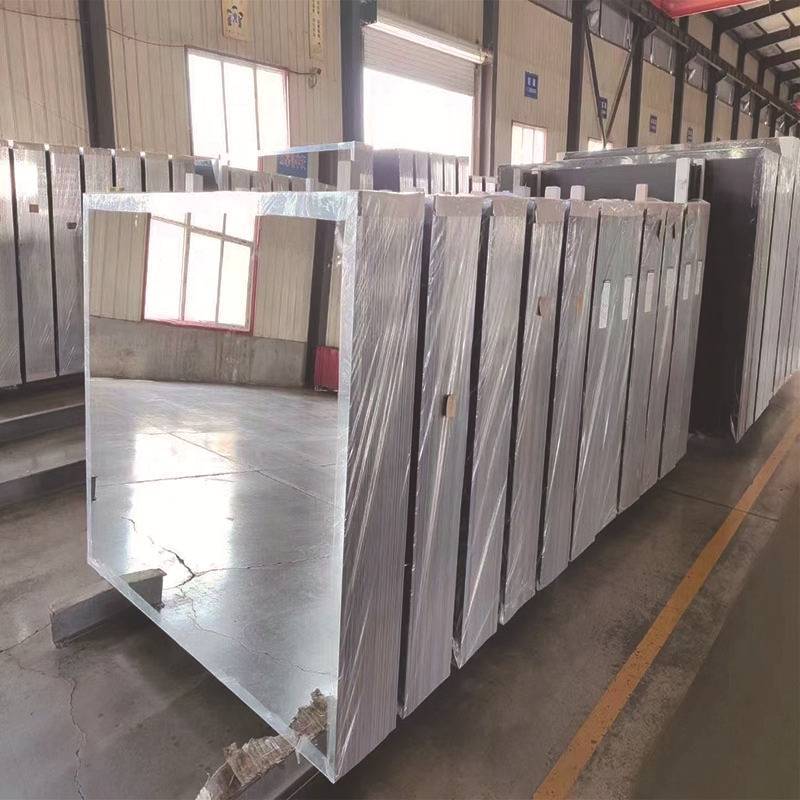

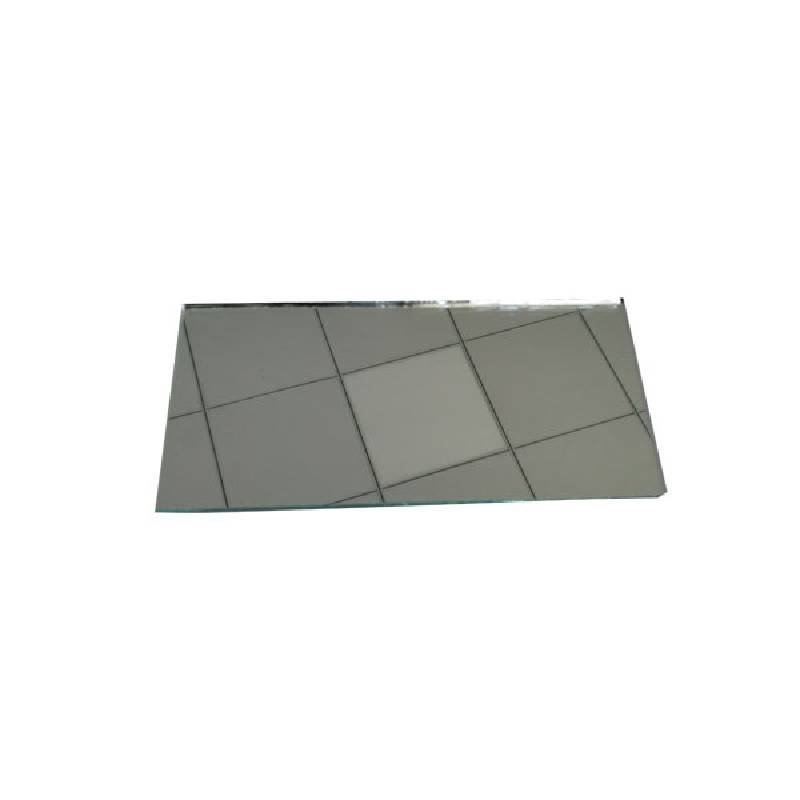

The aluminum mirror represents a milestone in optical and decorative industries. Also known as aluminized glass mirror, it is manufactured by processing high-quality float glass through multi-stage procedures: pure water washing, mechanical and chemical polishing, and metal magnetron sputtering deposition of aluminum. The result is a mirror with an aluminum metallic reflective layer at the back. Compared to silver mirrors, aluminum mirrors offer unique advantages including customizable colored mirror options (gray, brown, green, blue, etc.), macro sizes up to 2440x3660mm (96"x144"), and a practical thickness range from 1.1mm to 8mm.

The flexibility of aluminum mirror production processes enables adaptation for architectural, automotive, furniture, and high-end decorative applications. Globally, their increasing use marks a significant trend in sustainable and visually compelling spaces.

Key Parameters Table: Aluminum Mirror Solutions

| Parameter |

Description / Range |

| Material Base |

High-quality float glass |

| Coating Material |

Aluminum (via vacuum magnetron sputtering) |

| Thickness |

1.1mm – 8mm |

| Max Size |

2440 x 3660 mm (96"x144") |

| Reflectivity (Visible Light) |

82%–90% (depending on thickness and purity) |

| Edge Processing |

Flat edge, beveled, round, pencil-polished |

| Color Options |

Clear, black, gray, brown, green, blue, customizable |

| Environmental Standard |

RoHS, EN 1036, ASTM C1503 |

| Application |

Architecture, furniture, automotive, electronics, decor |

Visualizing Aluminum Mirror Technology Trends

Comparative Analysis: Aluminum Mirror vs. Other Mirrors

Aluminum Mirror Industry Trends & Market Insights

The global aluminum mirror marketplace is in the midst of rapid expansion, driven by green construction demands, digital architectural design, and evolving aesthetic preferences. Notably, black aluminum mirror and colored aluminium mirror glass options now dominate high-end decorative applications, automotive interiors, and smart device enclosures.

- Customization & Scale: Production now accommodates a plethora of colors, thicknesses, and edge finishes, making aluminum mirror a primary choice among designers and furniture manufacturers.

- Technological Innovation: Modern factories leverage high-vacuum magnetron sputtering lines for improved durability, optical clarity, and environmentally friendly coatings.

- Price Dynamics: According to market analytics, aluminum mirror price has steadily decreased due to increased automation, global competition, and raw material optimization. Reference: Glassonweb industry news

- Export Leadership: China remains the leading exporter, with a robust ecosystem of aluminum mirror manufacturers like SHZR Glass offering custom wholesale solutions worldwide.

Application Scenarios for Aluminum Mirror Solutions

Aluminum mirror versatility finds applications across the following scenarios:

- Architectural Decor: High-rise facades, wall cladding, elevator panels, lobby features.

- Furniture & Interior: Wardrobe doors, vanities, bathroom mirrors, shopfitting, gyms.

- Automotive: Rear view mirrors, instrument panels, interior trims.

- Retail & Commercial: Display cases, lighting reflectors, signage, advertising panels.

- Technical & Industrial Use: Solar reflectors, scientific instruments, smart devices.

The custom wholesale capabilities of SHZR Glass enable unique specifications for bulk projects. For more specification details and design options, explore our aluminum mirror product page.

FAQ: Professional Insights into Aluminum Mirror Technicalities

Q1: What is the main difference between aluminum mirrors and traditional silver mirrors?

A1: Aluminum mirrors utilize an aluminum reflective layer deposited on float glass, while silver mirrors use a silver nitrate coating. Aluminum mirrors offer better environmental sustainability, more color options, and very high durability against oxidation.

Q2: What thicknesses are available for aluminum mirror glass?

A2: Standard thicknesses include 1.1mm, 1.3mm, 1.5mm, 2mm, 2.7mm, 3mm, 4mm, 5mm, 6mm, and up to 8mm, suitable for a variety of installation and safety requirements.

Q3: Are black aluminum mirrors an option for modern interiors?

A3: Yes, black aluminum mirror is highly popular in luxury decor, offering deep hues and unique contrast for contemporary designs.

Q4: What is the production process for aluminum mirror?

A4: The process involves float glass washing, surface polishing, high-vacuum magnetron sputtering of aluminum, back protective coating application, and edge finishing for customized sizes and shapes.

Q5: How do aluminum mirror manufacturers ensure quality and reflectivity?

A5: Advanced inspection for optical clarity, substrate flatness, and reflectivity according to EN 1036, ASTM, and RoHS standards ensures stable, high-quality products.

Q6: What are the standard installation guidelines for aluminum mirror?

Q7: What is the typical aluminum mirror price for wholesale orders?

A7: Price varies by thickness, color, and quantity. For 4mm clear aluminum mirror, the average 2024 price is around $6–$7 per sqm, with possible discounts for large bulk orders.

For the latest quotations, contact lixia@zhuoruiglass.com or 8613673206180.

Partner with Leading Aluminum Mirror Manufacturers – SHZR Glass

SHZR Glass is a key player among aluminum mirror manufacturers globally, offering comprehensive custom wholesale services for aluminum mirror, black aluminum mirror, and aluminum mirror glass products. Our factory employs state-of-the-art production lines and globally recognized quality systems to guarantee consistent supply for large-scale and specialty projects.

References & Further Learning on Aluminum Mirror

Cited sources validate aluminum mirror technical superiority, sustainability, and broad market acceptance (2024).

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu