Laminated glass and tempered glass are two innovative products that have significantly transformed the construction and automotive industries. A deep understanding of these materials enhances decision-making concerning their application in various projects.

Laminated glass, recognized for its exceptional safety characteristics, consists of two or more layers of glass bonded with an interlayer, typically made of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA). This interlayer acts as a formidable barrier, ensuring that even if the glass breaks, it remains adhered to the interlayer, preventing the detachment of dangerous shards. This feature renders laminated glass ideal for automotive windshields and architectural designs where impact resistance is crucial.

The expertise surrounding laminated glass is profound. Its acoustic properties are unparalleled, effectively dampening noise and making it highly sought after in urban constructions that require noise mitigation. Furthermore, its UV-filtering capabilities provide added protection against harmful sun rays, preserving the longevity of interior furnishings and reducing energy costs associated with cooling.

Tempered glass, on the other hand, undergoes a thermal tempering process that enhances its strength and thermal resistance. This makes it nearly five times stronger than ordinary glass, a testament to its resilience and durability. One of the most frequently cited advantages is its safety profile; when shattered, tempered glass disintegrates into small granular chunks rather than jagged shards, minimizing injury risks. Consequently, it is extensively used in areas where human impact is likely, such as in glass doors, shower enclosures, and storefronts.

From an authoritative standpoint, tempered glass's thermal resistance makes it an optimal choice for environments exposed to extreme temperature fluctuations. Thus, it is commonly employed in oven doors, refrigerator shelves, and sunroofs in vehicles.

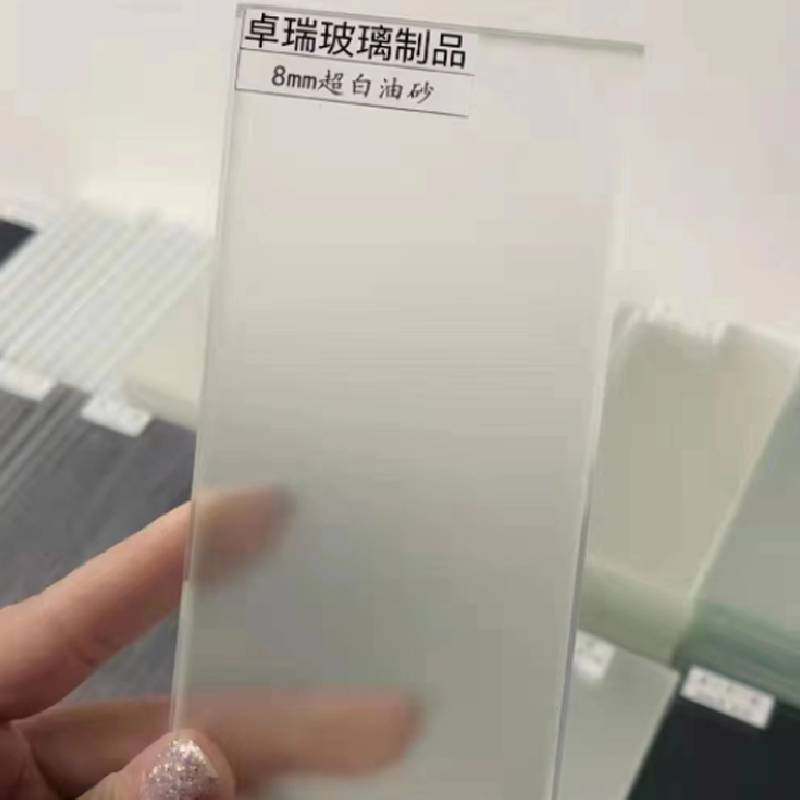

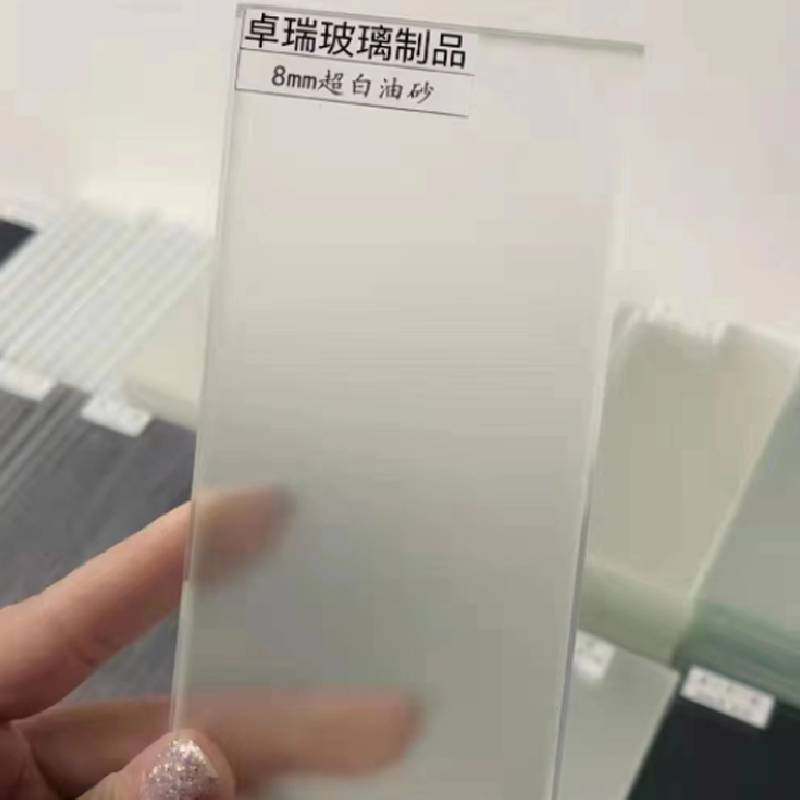

laminated glass and tempered glass

Despite their distinctive attributes, a comparative analysis between laminated and tempered glass is essential for informed material selection. Laminated glass excels in applications demanding security and soundproofing, often used in skylights, balustrades, and hurricane-resistant windows due to its ability to remain intact upon impact. On the contrary, tempered glass's quick installation and visual clarity make it preferable for projects emphasizing aesthetics and load resistance.

Trustworthiness in sourcing laminated and tempered glass is critical. Reputable manufacturers adhere to stringent production standards, such as those set by the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO). These standards ensure not only the durability and safety of the glass but also its environmental impact and quality assurance.

To leverage the maximum potential of both types of glass, collaboration with accredited experts and architects leads to more innovative and efficient integration within structures. This relationship fosters trust and facilitates projects that require precise customization and adherence to safety regulations.

In conclusion, both laminated and tempered glass advocate for advancements in safety, energy efficiency, and design flexibility. As two formidable products in the glass industry, each has distinct qualities that cater to specific project needs. Understanding their unique properties and applications ensures optimal usage and client satisfaction, placing emphasis on an informed choice that aligns with modern architectural and safety standards. This expertise is invaluable in a world increasingly veering towards sustainable and safe construction practices.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu