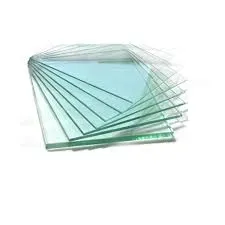

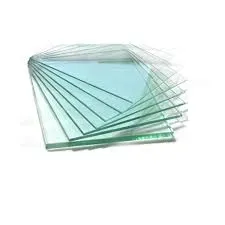

In the rapidly evolving construction and interior design industries, laminated tempered glass stands out as a material of choice for both safety and aesthetics. Its unique properties make it indispensable in a variety of applications, from skyscraper facades to elegant shower enclosures. Understanding the pricing of laminated tempered glass requires not only a knowledge of its production but also the market dynamics that influence its cost.

Laminated tempered glass is formed through a multifaceted process that enhances its durability and safety. The glass is initially tempered through a thermal treatment that increases its strength compared to standard glass. Laminating involves sandwiching the tempered glass around a polyvinyl butyral (PVB) layer. This process ensures that if the glass is broken, the fragments remain stuck to the PVB layer, significantly reducing the risk of injury.

The costs associated with laminated tempered glass derive from several key factors. Firstly, the raw material costs can significantly influence price. The quality of the glass and the PVB interlayer are critical components. Glass with higher clarity and strength ratings tends to command a premium price. Similarly, PVB layers come with varying properties, such as thickness and acoustic insulation, which can drive up costs.

Another vital factor is the complexity of customization. Architects and designers often require bespoke solutions that entail specific shapes, sizes, and finishes. The intricacies involved in customizing laminated tempered glass, such as edgework (polishing and beveling), decorative elements, and tinting, directly influence the final price. The more intricate the customization, the higher the cost, due to increased labor and resource allocation.

Geographical location also plays a pivotal role in price variation. Transportation costs can vary greatly depending on proximity to manufacturing hubs or shipping ports. Additionally, local demand and competition among suppliers can lead to price fluctuations. In regions with a high number of construction projects, higher demand can drive up prices, whereas in less active areas, prices might be more competitive.

laminated tempered glass price

Scale and volume further impact pricing. Bulk orders typically offer economies of scale, reducing the per-unit cost for large construction projects or commercial applications. This factor is particularly relevant for businesses involved in extensive construction projects or real estate development, where cost efficiency is paramount.

Market trends and technological advancements continually shape the pricing landscape of laminated tempered glass. As sustainability becomes a priority, there is a growing demand for eco-friendly materials, including low-e glass that improves energy efficiency. While such innovations can raise production costs, they also add value by contributing to sustainability goals and reducing long-term operational expenses.

Engaging with reputable suppliers who can demonstrate compliance with safety standards is critical in ensuring product quality and reliability. Certifications from recognized bodies such as the International Organization for Standardization (ISO) can influence both perception and pricing, as they guarantee the glass meets rigorous safety and quality benchmarks.

In conclusion, the price of laminated tempered glass is a multifaceted reflection of material quality, customization complexity, geographical location, order scale, and emerging market trends. Customers seeking to procure this essential material should carefully evaluate these factors, aligning them with project specifications and budget constraints. Partnering with knowledgeable industry professionals ensures informed decision-making and the selection of a product that delivers both safety and aesthetic value, ultimately enhancing the structural and visual appeal of the architectural project.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu