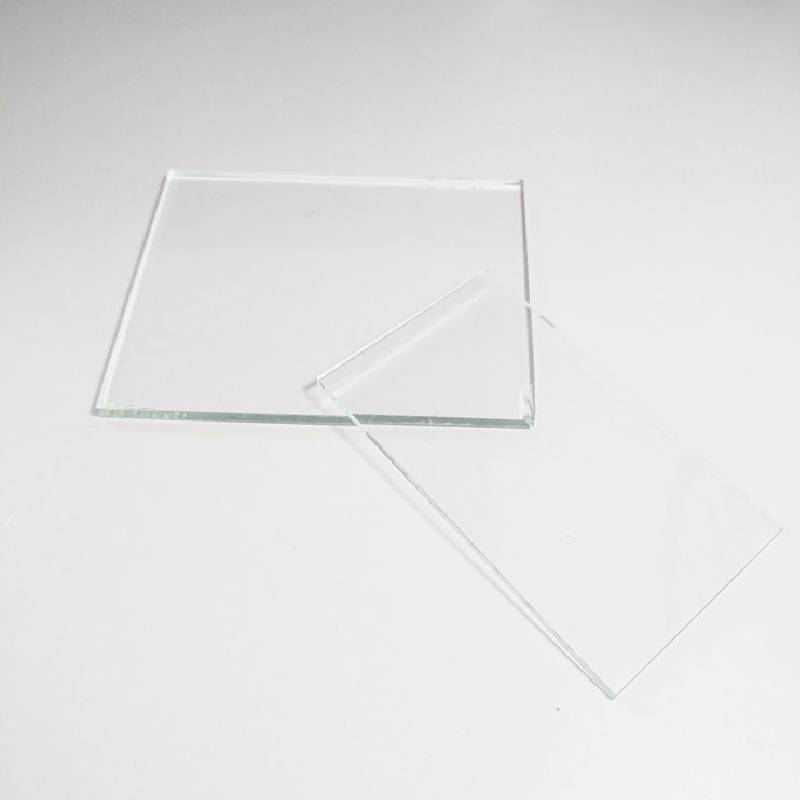

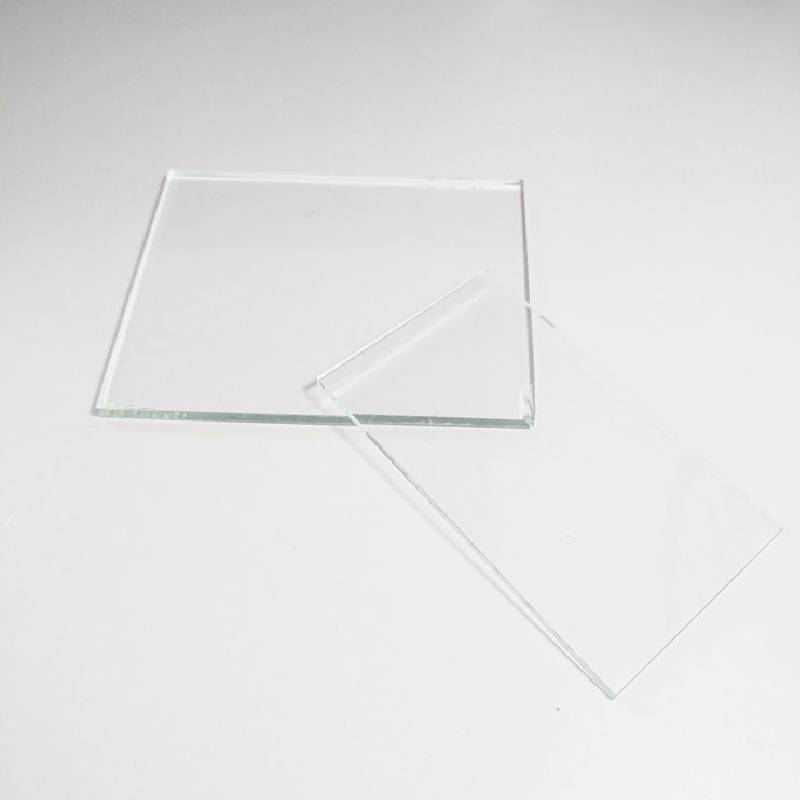

Low Iron Glass A Transparent Innovation

Low iron glass, also known as clear or ultra-clear glass, is a specialized type of glass that has gained prominence in various industries, particularly in architecture, automotive, and solar energy sectors. Unlike conventional glass, which contains iron oxide and thus has a greenish tint, low iron glass is manufactured using raw materials that have minimal iron content. This results in higher light transmission and color clarity, making it an ideal choice for applications where transparency and aesthetic appeal are paramount.

The Manufacturing Process

The production of low iron glass begins with the selection of high-quality raw materials, especially silica sand, which is low in iron. The glass is produced through a melting process at high temperatures, around 1,600 degrees Celsius. The reduced iron content is key; during this process, the aim is to ensure that the glass remains free from impurities that can affect its clarity. Advanced manufacturing techniques further enhance the quality of low iron glass, enabling smoother surfaces and increased durability. Once the molten glass is formed, it is cooled and processed into sheets or other desired shapes.

Applications and Benefits

1. Architectural Use One of the most significant applications of low iron glass is in architectural design. It is widely used in facades, skylights, and curtain walls, where natural light is essential. The high transparency and minimal color distortion allow for excellent visual aesthetics, making buildings more inviting and energy-efficient. This type of glass allows designers to create airy, open spaces flooded with light, while maintaining the structural integrity of the building.

2. Solar Energy Low iron glass also plays a crucial role in the solar energy sector, particularly in photovoltaic panels. Since it allows for a greater transmission of sunlight, it enhances the efficiency of solar cells. The increased clarity of low iron glass means that more sunlight can penetrate the panels, thereby improving energy conversion rates. With the rising demand for renewable energy sources, the importance of low iron glass in solar technology cannot be overstated.

low iron glass

3. Automotive Industry In the automotive sector, low iron glass is used in the production of windshields and windows. The enhanced clarity provides better visibility for drivers and passengers. Furthermore, the glass is often treated to be stronger and more resistant to shattering, which adds a layer of safety. Additionally, vehicles made with low iron glass can have tinted options without sacrificing transparency, offering both style and functionality.

Environmental Impact

The production and use of low iron glass also have environmental implications. By enabling better energy efficiency in buildings and solar panels, it contributes to reduced energy consumption. Moreover, many manufacturers are now focusing on sustainable practices in their glass production, including recycling processes and the use of energy-efficient technologies.

Challenges and Future Prospects

While low iron glass presents numerous advantages, it is not without its challenges. The manufacturing process can be more costly compared to traditional glass, and its availability may be limited in certain regions. Nonetheless, the market for low iron glass is expected to grow, driven by trends in sustainable architecture and green building practices.

As innovations continue to emerge in manufacturing techniques and applications, the future of low iron glass looks promising. Researchers are exploring ways to further enhance its properties, such as improving its strength and reducing production costs. The growing awareness of environmental sustainability and energy efficiency will likely propel the demand for low iron glass across various industries, fostering a shift towards more transparent and eco-friendly solutions.

In conclusion, low iron glass represents a significant advancement in material technology, offering unparalleled clarity and efficiency in multiple applications. As industries increasingly prioritize sustainability, the role of low iron glass will only become more prominent, paving the way for a brighter and clearer future.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu