The Rise of Low Iron Glass Factories A Closer Look at Their Impact and Innovations

In recent years, the glass industry has recorded an impressive transformation with the advent of low iron glass technology. This innovation has significantly altered the landscape of glass production and application, leading to the establishment of specialized manufacturing facilities known as low iron glass factories. These factories are dedicated to producing glass with exceptionally low iron content, thus ensuring higher clarity and transparency. As we delve into the intricacies of low iron glass, it becomes evident that these factories play a crucial role in various industries, from architecture to renewable energy.

Understanding Low Iron Glass

Low iron glass, often referred to as ultra-clear glass, contains a minimal amount of iron oxides—typically less than 0.1%. This reduction in iron not only enhances the colorless appearance of the glass but also improves its optical properties. The high level of clarity makes it ideal for applications where visibility is critical, such as in display cases, glass facades, and solar panels. The purity of low iron glass allows for a change in light transmission and minimizes color distortion, making it a preferred choice among architects and designers.

The Growth of Low Iron Glass Factories

The global demand for low iron glass has seen significant growth, remarkably impacting the development of specialized factories. These facilities are equipped with advanced technology that enables high-precision production methods. The last decade has witnessed a surge in the construction of low iron glass manufacturing plants, particularly in regions where building and construction are booming.

For example, countries in the Asia-Pacific region have emerged as key players in the low iron glass market due to rapid urbanization and industrial growth. Nations such as China and India have seen an influx of investments in glass production technologies, along with a rising demand for energy-efficient and aesthetically pleasing architecture. These factories not only contribute to local economies by creating jobs but also foster innovation in glass manufacturing techniques.

Environmental Considerations

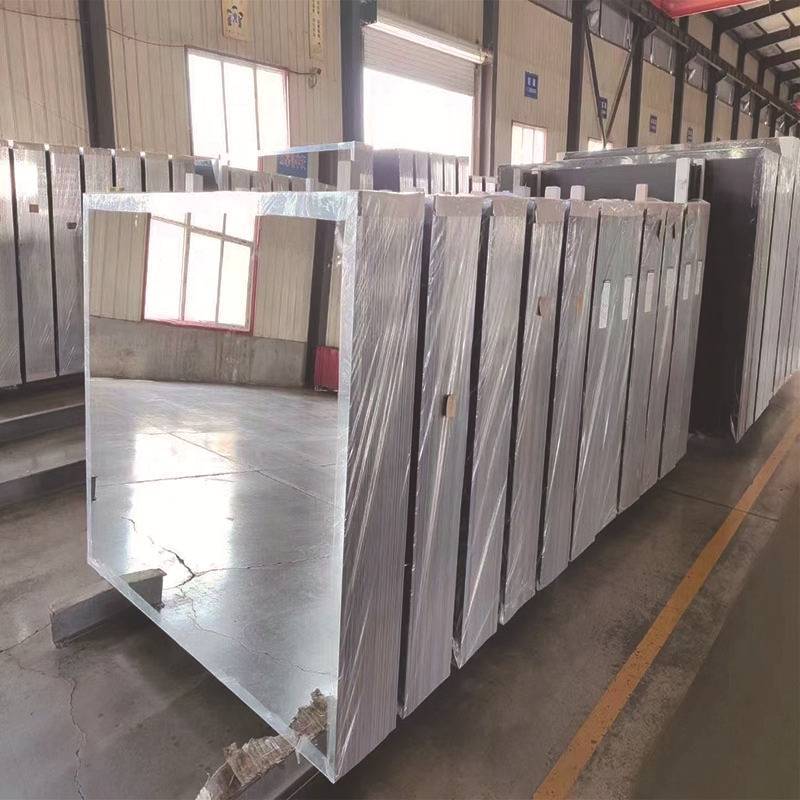

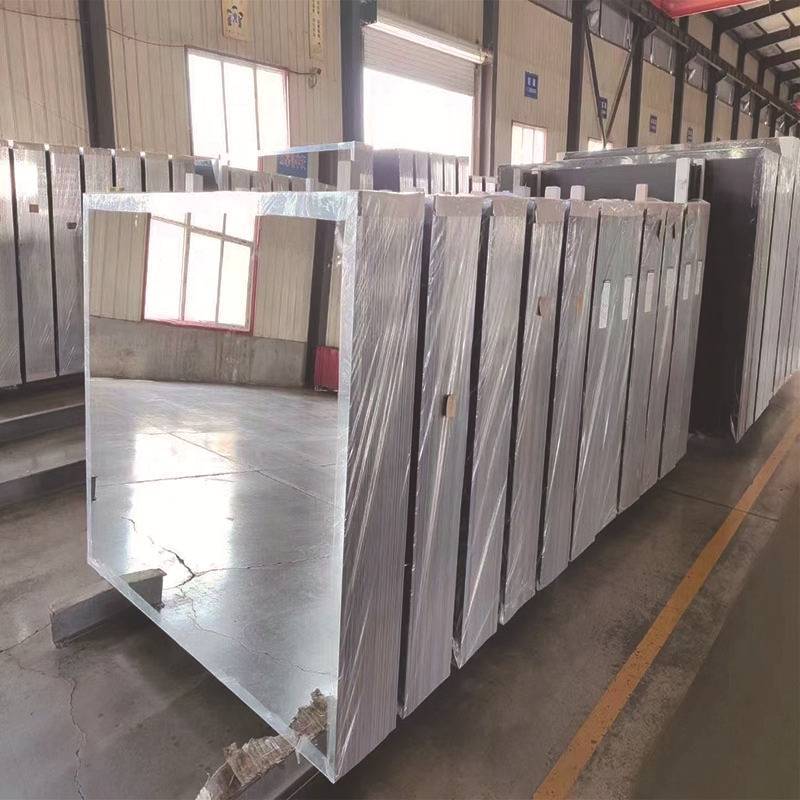

low iron glass factory

One significant advantage of low iron glass factories is their potential environmental benefits. Traditional glass production is energy-intensive and often results in significant CO2 emissions. However, modern low iron glass facilities are increasingly incorporating sustainable practices and technologies to minimize their environmental footprint.

Many manufacturers are investing in renewable energy sources, such as solar and wind power, to fuel their operations. Additionally, advancements in production techniques have led to increased recycling of glass materials, which reduces the demand for raw materials and the energy required for production. By adopting such strategies, low iron glass factories can effectively contribute to the global effort towards sustainability.

Applications Across Industries

The versatility of low iron glass has led to its adoption across a plethora of industries. In architecture, its transparency and aesthetic appeal make it an attractive choice for facades, skylights, and curtain walls. Buildings adorned with low iron glass not only enhance natural light penetration but also create visually stunning structures that stand out in urban landscapes.

In the renewable energy sector, low iron glass plays a pivotal role in solar technology. Photovoltaic solar panels utilize low iron glass for enhanced light transmission, improving the efficiency of solar energy conversion. As the world transitions toward sustainable energy sources, the demand for high-quality low iron glass in solar applications continues to rise.

Furthermore, the automotive industry is also embracing low iron glass for windshields and windows, where clarity and visibility are paramount. The safety benefits associated with unobstructed views are pushing manufacturers to incorporate low iron glass into their designs.

Conclusion

In summary, the emergence of low iron glass factories marks a significant advancement in glass technology and production. These specialized facilities not only meet the growing demand for high-clarity glass but also contribute to environmental sustainability and innovation across various sectors. As industries continue to evolve, the contributions of low iron glass will likely expand, showcasing the essential nature of these factories in our modern world. The journey of low iron glass from production to application illustrates the intersection of technology, design, and sustainability—an intersection that will undoubtedly shape the future of the glass industry.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu