Low Iron Glass Manufacturers A Comprehensive Overview

Low iron glass, often referred to as ultra-clear glass, is a high-quality material known for its exceptional transparency and clarity. Unlike traditional glass, which may have a greenish tint due to the presence of iron oxide, low iron glass is manufactured with significantly reduced levels of iron, resulting in a colorless appearance. This unique attribute makes it highly sought after in various applications, including architecture, glass facades, solar panels, and interior design. As the demand for low iron glass continues to rise, manufacturers play a pivotal role in meeting industry needs.

Key Features of Low Iron Glass

1. High Clarity and Transparency The primary characteristic that distinguishes low iron glass is its superior optical clarity. This feature allows for maximum light transmission and minimizes distortion, providing an unobstructed view. This is particularly important in applications such as display cases, where aesthetics and visibility are paramount.

2. Enhanced Solar Performance Low iron glass is increasingly used in solar energy applications. Its high light transmission properties enable solar panels to harness more sunlight, thereby improving efficiency. As the global demand for renewable energy solutions grows, manufacturers of low iron glass are positioned to play a crucial role in this sector.

3. Customizable Thickness and Sizes Many manufacturers offer low iron glass in various thicknesses and sizes, allowing for customization based on specific project requirements. This flexibility is essential for architects and designers who seek tailored solutions for their projects.

4. Durability and Strength Low iron glass is not only aesthetically pleasing but also durable and strong. It is manufactured using tempered processes that increase its resistance to impact and thermal stress, making it suitable for both residential and commercial applications.

The Manufacturing Process

The production of low iron glass involves several critical steps to ensure the desired quality and characteristics. The process begins with the careful selection of raw materials. High-purity silica sand is used, along with other additives that contribute to the glass's final properties. The manufacturing process typically involves heating the raw materials in a furnace at high temperatures until they melt and form molten glass.

Once the glass is formed, it undergoes a refining process to remove impurities, particularly iron. This is achieved through specialized techniques and equipment designed to minimize the introduction of iron oxide during production. After refining, the glass is then shaped and cooled in a controlled environment to produce sheets of low iron glass with consistent thickness and quality.

Major Players in the Low Iron Glass Market

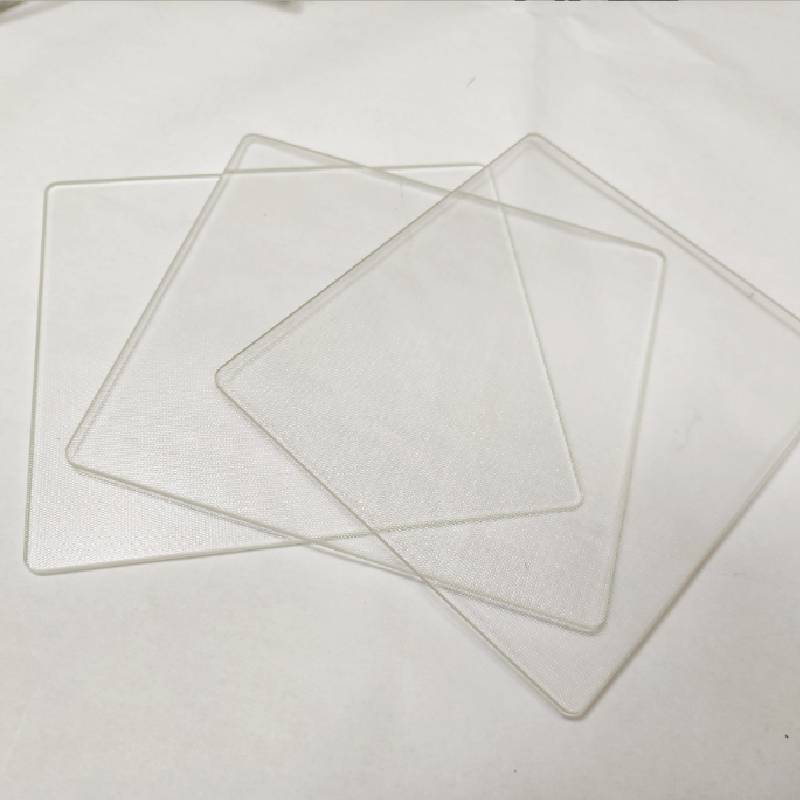

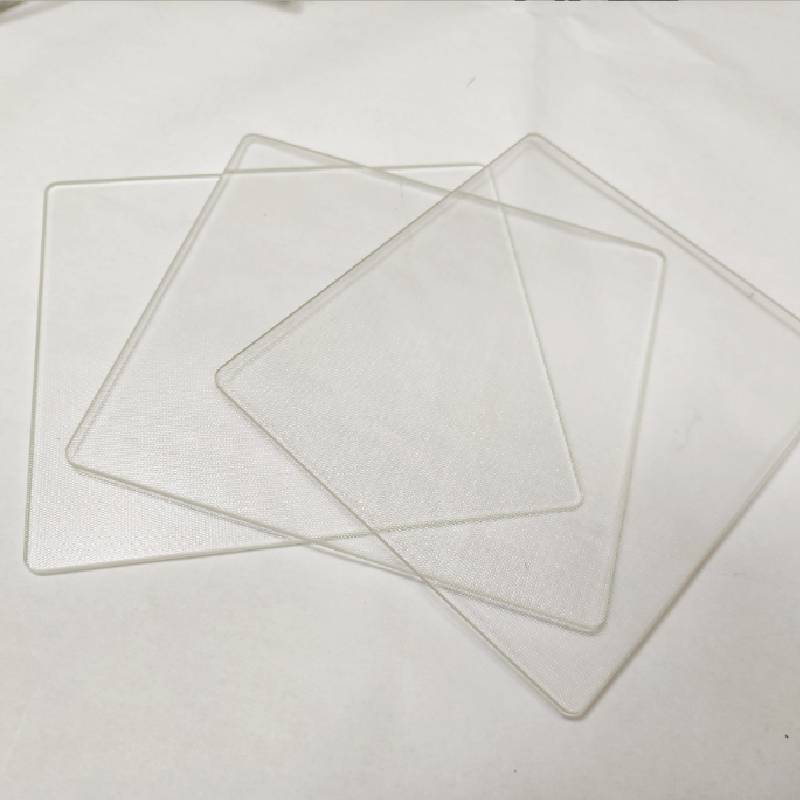

low iron glass manufacturers

Several manufacturers are recognized for their expertise in producing low iron glass. These companies leverage advanced technologies and rigorous quality control processes to meet the growing demand across various sectors. Some of the notable low iron glass manufacturers include

1. Saint-Gobain Glass A global leader in glass manufacturing, Saint-Gobain offers a range of low iron glass products tailored for construction, automotive, and solar applications.

2. AGC Glass Europe With a commitment to sustainability and innovation, AGC produces ultra-clear glass solutions that meet the needs of architects and builders while focusing on energy efficiency.

3. Pilkington Part of the NSG Group, Pilkington specializes in architectural glass, including low iron options that provide clarity and strength for diverse applications.

4. Guardian Glass Known for its advanced glass technologies, Guardian Glass produces low iron glass for commercial and residential uses, emphasizing performance and aesthetic value.

5. Bendheim A family-owned business, Bendheim is renowned for its decorative glass solutions, including low iron glass products used in high-end architectural projects.

Future Trends and Conclusion

As sustainability becomes increasingly important, low iron glass is poised for growth due to its energy-efficient properties and aesthetic appeal. The architectural industry is moving towards greater use of glass in buildings for natural lighting and energy savings, which will likely drive demand for low iron glass.

Manufacturers are also exploring innovative processing techniques and materials to enhance the performance of low iron glass further. With advancements in technology, the future may see the development of even more transparent and energy-efficient glass products.

In conclusion, low iron glass manufacturers are crucial players in meeting the demands of various industries. Their commitment to quality, innovation, and sustainability positions them favorably in a rapidly evolving market, where clarity and energy efficiency are of utmost importance. As the world continues to embrace sustainable building practices and renewable energy solutions, the role of low iron glass will undoubtedly expand, shaping the future of architectural design and construction.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu