The Emergence of Low Iron Glass Manufacturers A Glimpse into the Future of Building Materials

In recent years, the construction and architectural industries have seen significant advancements in materials science, one of the most notable being low iron glass. This specialized glass, characterized by its minimal iron content, offers exceptional clarity and aesthetic appeal. As a result, the market for low iron glass manufacturers is rapidly expanding, driven by an increasing demand for high-quality glass products in various applications, including commercial buildings, residential homes, and even in automotive design.

The Characteristics of Low Iron Glass

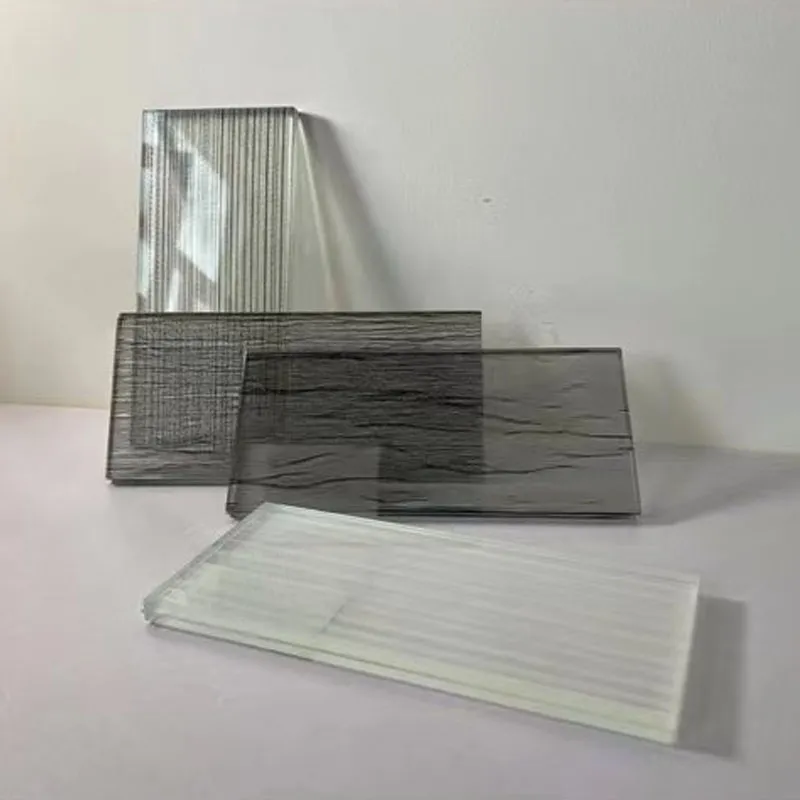

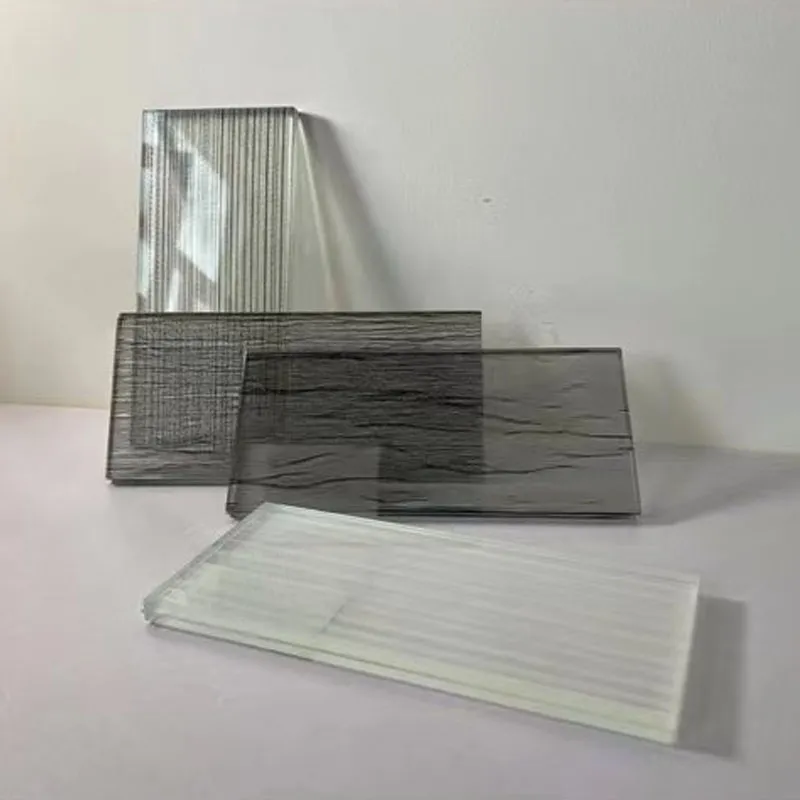

Low iron glass, often referred to as ultra-clear glass, is produced by reducing the iron oxide content during the glass manufacturing process. This results in a transparent product that allows up to 90% of visible light to pass through, significantly more than standard float glass, which typically contains higher iron content. The enhanced optical clarity makes low iron glass an ideal choice for applications where visibility and aesthetic appeal are paramount. From expansive glass facades in modern architecture to customized glass displays in retail environments, the uses for this type of glass are virtually limitless.

Another key characteristic of low iron glass is its superior color neutrality. Standard glass tends to have a greenish tint due to the iron content, which can affect the overall look of structures where large glass surfaces are used. In contrast, low iron glass ensures that colors remain true and unchanged, a critical factor in high-end design and architecture. This attribute not only enhances the visual aspect but also ensures more accurate color rendering in spaces such as galleries and museums, where artwork needs to be displayed under the best possible light conditions.

The Manufacturing Process

The production of low iron glass involves several complex steps, starting with the selection of raw materials. Manufacturers focus on sourcing high-purity silica sand, soda ash, and dolomite, avoiding impurities that could introduce iron into the final product. The melting process is conducted in specialized furnaces designed to achieve the precise temperatures required for optimal glass formation while maintaining low iron levels. Following this, the glass is conditioned and formed into sheets through advanced techniques that ensure uniform thickness and quality.

low iron glass manufacturers

Once produced, low iron glass can undergo various treatments to enhance its properties. These include thermal tempering, which increases strength and durability, and surface coatings that improve performance in terms of solar control and energy efficiency. Manufacturers often invest in state-of-the-art technology to not only produce high-quality glass but also to implement sustainable practices, focusing on reducing waste and energy consumption during the production cycle.

Market Demand and Applications

The increasing demand for low iron glass is largely fueled by the booming construction industry and a growing trend toward sustainable architecture. As more architects and builders seek to create energy-efficient structures with expansive glass features, the need for high-performance materials becomes critical. Low iron glass aligns perfectly with these needs, providing solutions that enhance natural light without compromising on energy efficiency.

In addition to commercial and residential buildings, low iron glass is seeing increased applications in the automotive industry. Car manufacturers are increasingly using this type of glass in sunroofs and windshields, where visibility is crucial. The clarity and light transmittance of low iron glass help in creating a more pleasurable driving experience, allowing for a seamless connection to the outside world.

Future Prospects

As the demand for low iron glass continues to grow, manufacturers are poised to expand their production capabilities and innovate further. The ongoing development in smart glass technologies, which combine low iron glass with advanced electronics to create products that can change their properties—such as tint or opacity—will likely shape the future of the industry. This combination of aesthetics, functionality, and sustainability makes low iron glass a critical player in the evolution of modern materials.

In summary, low iron glass manufacturers are at the forefront of a revolution in building materials, responding to the needs of a market driven by aesthetics, energy efficiency, and innovation. With its unmatched clarity and versatility, low iron glass is not just an option but a preferred choice for a wide array of applications, marking a significant shift in how we approach design and construction in the 21st century. As we look to the future, the role of these manufacturers will undoubtedly become even more significant, driven by a collective ambition for sustainability and excellence in building materials.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu