Low Iron Glass Manufacturers A Gateway to Clarity and Precision

Low iron glass, renowned for its exceptional clarity and high light transmission, has become an essential material in various sectors, including architecture, automotive, and solar energy. Unlike traditional glass, which contains iron oxide that imparts a greenish tint, low iron glass boasts minimal impurities, making it an ideal choice for applications where transparency and aesthetics are paramount. This article explores the significance of low iron glass manufacturers, their contributions to various industries, and the technological advancements shaping the production of this remarkable material.

Understanding Low Iron Glass

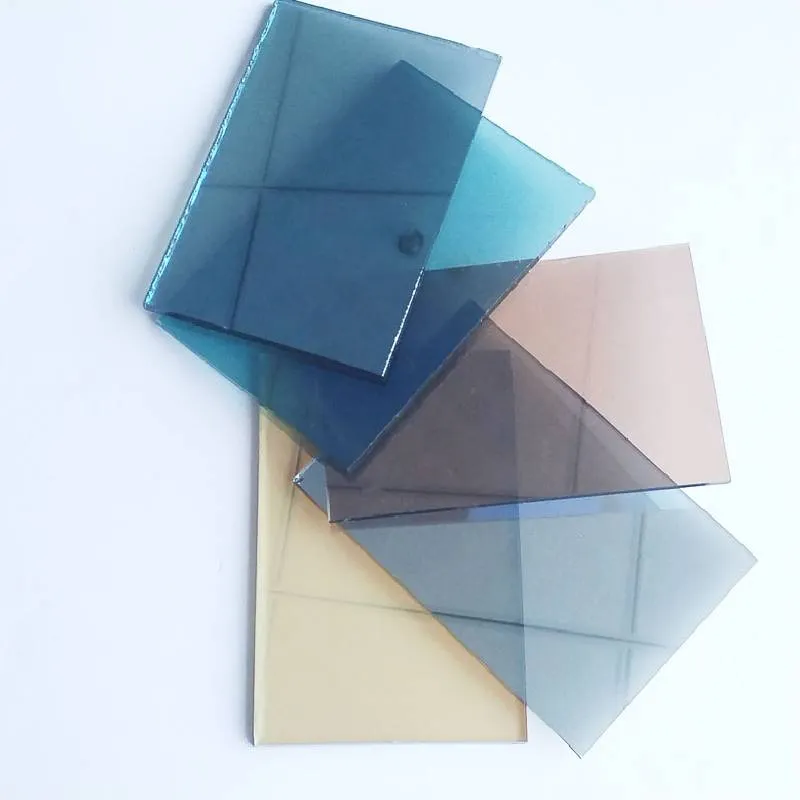

Low iron glass contains significantly lower levels of iron oxide, resulting in a clearer and more transparent product. Typically, the iron content in standard glass can lead to distortions in color and light quality, which can be detrimental in applications such as display cases, interiors, and glass facades. By reducing the iron content, manufacturers produce glass that transmits over 91% of visible light, making it the optimal choice for projects that require high levels of brightness and color accuracy.

Applications of Low Iron Glass

The applications of low iron glass are diverse and continue to grow as technology advances. In the architectural sector, low iron glass is utilized for facades, skylights, and curtain walls, where visual appeal and light transmission are crucial. The trend towards larger glass surfaces in modern architecture can often result in the need for enhanced structural support, which low iron glass is particularly well-equipped to provide due to its strength and lightweight properties.

In the automotive industry, low iron glass is commonly used in vehicle windows and windshield designs. It not only decreases weight, contributing to improved fuel efficiency, but also enhances visibility for drivers and passengers alike. With the rise of electric vehicles, the demand for lightweight materials that can support sustainable practices is growing, making low iron glass an attractive option.

Another significant application is in solar energy technology. Low iron glass is used in solar panels where high transparency is essential for maximizing light absorption and conversion into energy. The photovoltaic industry benefits from low iron glass, as it allows for more sunlight to penetrate and be converted into electricity, which is vital for improving the efficiency of solar technologies.

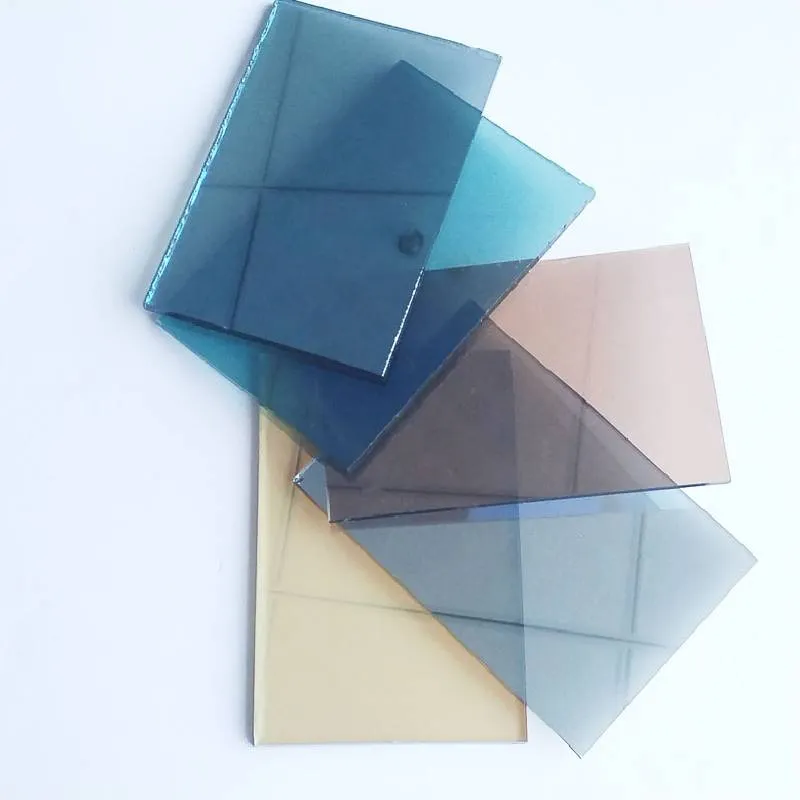

low iron glass manufacturers

The Role of Manufacturers

Low iron glass manufacturers play a pivotal role in ensuring the availability and quality of this specialized product. These manufacturers invest in advanced melting and production technologies to achieve the required purity and optical specifications. The process typically involves sourcing high-quality raw materials and employing stringent quality control measures to monitor iron content and overall glass characteristics.

Leading manufacturers often collaborate with architects and engineers to develop customized solutions tailored to specific applications. This collaborative approach not only fosters innovation but also helps in addressing unique challenges that arise in various projects, such as durability requirements, thickness, and thermal performance.

Technological Innovations

The glass industry has witnessed significant technological advancements over the years, especially in the production of low iron glass. Innovations such as new melting processes, automated quality testing systems, and enhanced coating technologies have drastically improved the quality and performance of glass products. These advancements allow manufacturers to develop a wider range of low iron glass products, including laminated and tempered versions that enhance safety and security.

Sustainability has also become a focal point in the glass manufacturing sector. Many manufacturers are adopting eco-friendly practices, such as recycling glass cullet in the production process, which not only reduces waste but also lowers energy consumption. As the emphasis on sustainable construction continues to grow, low iron glass manufacturers are positioned to lead the market by promoting green building practices.

Conclusion

In conclusion, low iron glass manufacturers play a crucial role in providing high-quality, transparent glass solutions across multiple industries. With applications ranging from architecture to automotive and renewable energy, low iron glass stands as a testament to the advancements in glass technology. As manufacturers continue to innovate and focus on sustainability, the future appears bright for low iron glass, promising even greater clarity and environmental responsibility in the years to come.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu