Understanding Low Iron Tempered Glass Pricing

Low iron tempered glass, often regarded as the premium choice in the market for glass products, offers unparalleled clarity and aesthetic appeal compared to regular glass. Its unique properties make it a favored material in various applications, including architecture, automotive, and decorative designs. However, when considering a purchase, customers frequently want to know about the pricing dynamics of low iron tempered glass. This article delves into the factors that influence its cost and provides insights into making informed purchasing decisions.

What is Low Iron Tempered Glass?

Low iron tempered glass is produced by refining raw materials to minimize the iron content, resulting in a clearer and more transparent product. The reduction of iron enhances light transmission, allowing up to 91% of visible light to pass through, which is significantly higher than that of standard glass. This quality makes it particularly appealing for large facades, glass railings, shower enclosures, and other applications where visibility and aesthetics are critical.

Furthermore, tempering the glass increases its strength, making it more resistant to thermal stress and impact. Tempered glass can be up to five times stronger than standard glass, allowing it to withstand tough conditions. These characteristics come at a price, and understanding the factors that contribute to this cost is essential for consumers.

Factors Affecting the Price of Low Iron Tempered Glass

1. Raw Material Quality The cost of manufacturing low iron tempered glass begins with the raw materials used. High-quality silica sand with minimal impurities is essential for producing low iron glass. The sourcing of these materials, their quality, and the processing methods will influence the overall price.

2. Manufacturing Process The production of low iron tempered glass is more complex and requires advanced technology compared to regular glass. The tempering process, which involves heating and cooling the glass to increase its strength, adds to the manufacturing costs. Facilities equipped with state-of-the-art technology will charge more for the enhanced efficiency and quality assurance.

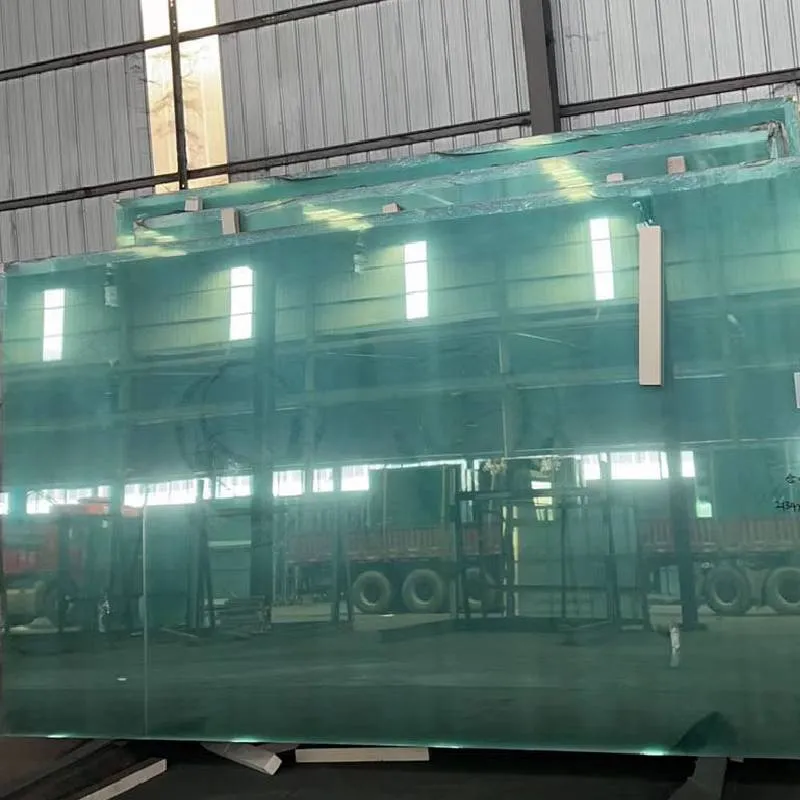

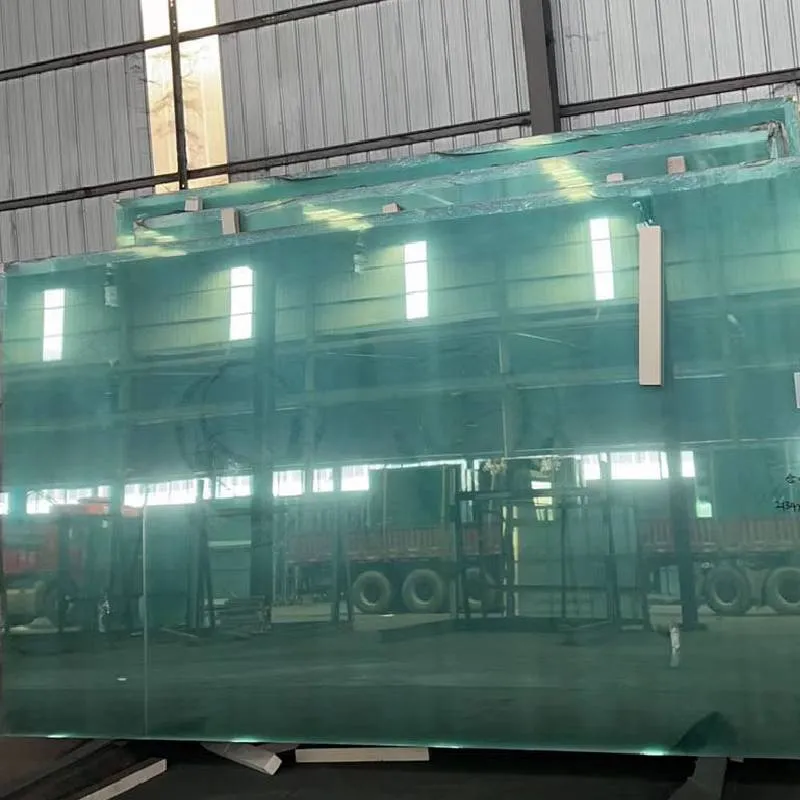

low iron tempered glass price

3. Thickness and Size Customization plays a significant role in pricing. The thickness of the glass can range from 2mm to over 19mm, depending on the application requirements. Thicker glass typically costs more due to the additional material and the more energy-intensive production processes. Additionally, larger panels of glass often come with higher shipping costs due to their size and weight.

4. Finishes and Coatings Clients may choose various finishes or coatings for their low iron tempered glass to enhance aesthetics or functionality. These can include polished edges, frosted surfaces, or specialized coatings for UV resistance or energy efficiency. Each of these options can affect the price, as they require specific treatments during the manufacturing process.

5. Market Demand and Supply The general market conditions also play a significant role in pricing. High demand for low iron tempered glass in architectural projects, increasing construction activities, or trends favoring large glass installations can drive prices higher. Conversely, market saturation and reduced demand may result in competitive pricing.

6. Shipping and Handling Given the fragile nature of glass, shipping and handling costs can be substantial. Protective packaging, freight insurance, and transportation logistics can add to the overall price. Companies often factor these costs into their pricing structures.

7. Geographical Factors Pricing may also vary based on geographical location. Regions with higher labor costs, transportation expenses, or taxes may see increased prices. Similarly, proximity to manufacturers can affect shipping costs and availability.

Conclusion

When considering purchasing low iron tempered glass, it's crucial to understand the various factors that affect its pricing. While the initial cost may seem high, the long-term benefits in terms of strength, clarity, and aesthetic appeal often outweigh the upfront investment. It’s advisable for consumers to obtain quotes from multiple suppliers, compare quality, and consider the long-term value of their investment.

In conclusion, low iron tempered glass is an excellent choice for those looking to enhance the beauty and durability of their projects. By understanding the factors impacting pricing, consumers can make informed decisions that align with their budget and project requirements. Whether for residential or commercial use, investing in this high-quality material can lead to impressive results that stand the test of time.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu