The Process of Making Tempered Glass

Tempered glass, also known as toughened glass, is a popular choice in various applications due to its strength, safety features, and aesthetic appeal. The process of making tempered glass involves several critical steps that enhance its durability by altering its physical properties. This article will delve into the stages of tempered glass production, its benefits, and its myriad uses.

The Manufacturing Process

The production of tempered glass begins with the selection of high-quality raw materials, typically soda-lime glass. This type of glass is favored for its excellent clarity and workability. Once the raw materials are gathered, they are melted in a furnace at temperatures exceeding 1,500 degrees Fahrenheit (800 degrees Celsius). This phase ensures a uniform composition, free from impurities.

After melting, the molten glass is shaped into flat sheets, often through a process known as floating. In the float glass method, the molten glass is poured onto a bed of molten tin, where it spreads out evenly to form flat sheets. Once the sheets cool down to a manageable temperature, they are cut into the desired dimensions.

Next, the glass sheets undergo an annealing process, which allows them to cool gradually to relieve internal stress. However, this step is just the precursor to the transformative aspect of glass production – the tempering phase.

Tempering Process

The tempering process is where the glass truly gains its strength. The cooled glass sheets are moved to an oven, where they are heated to temperatures ranging from 1,100 to 1,300 degrees Fahrenheit (600 to 700 degrees Celsius). This high-temperature environment allows the glass to reach a point where it becomes malleable but not liquid.

After achieving the desired temperature, the glass is rapidly cooled in a process known as quenching. High-pressure jets of cool air are directed onto the surface of the glass, causing the outer layers to cool quickly while the interior remains at a higher temperature for a short period. This rapid cooling process creates compressive stresses on the surface of the glass and tensile stresses on the inside, resulting in a dramatically increased strength.

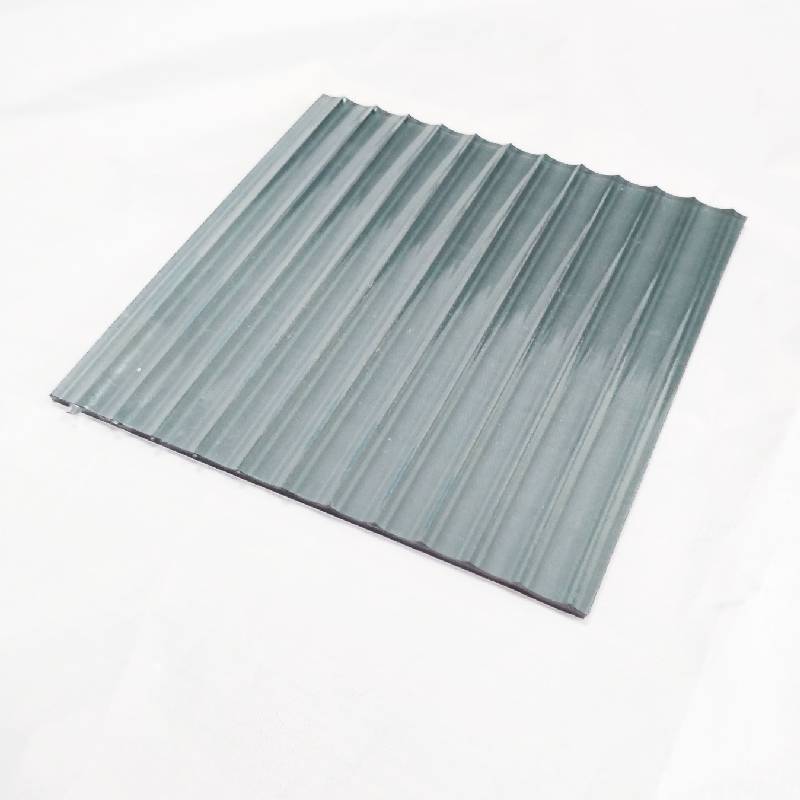

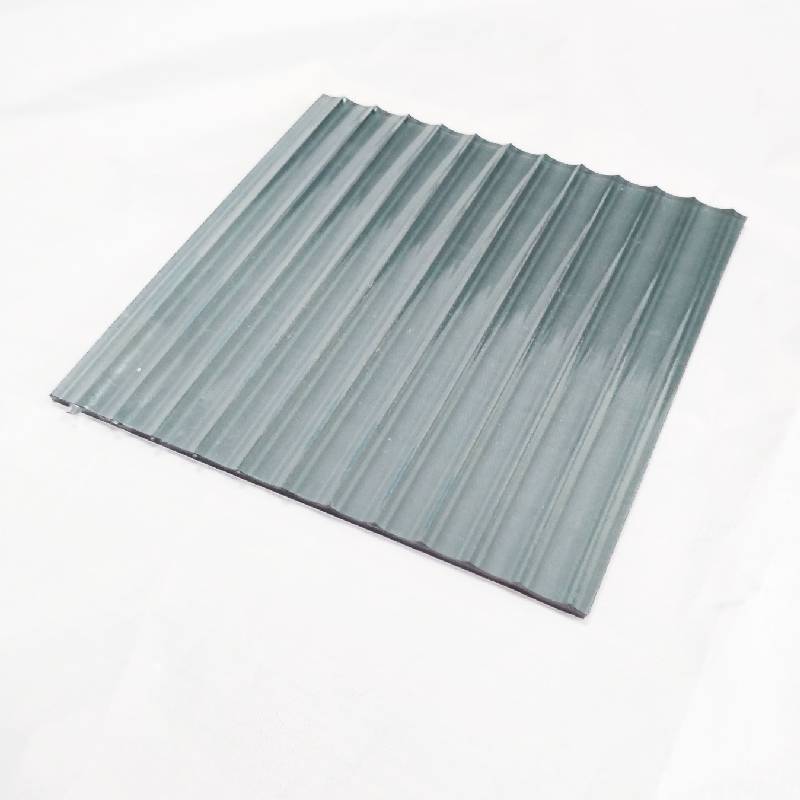

making tempered glass

The end result is tempered glass that is five to six times stronger than standard glass of the same thickness. Additionally, if tempered glass breaks, it shatters into small, blunt pieces rather than sharp shards, reducing the risk of injury.

Benefits of Tempered Glass

The advantages of tempered glass make it a preferred option in numerous settings. Its enhanced strength makes it ideal for applications such as shower doors, glass railings, and storefronts, where safety is a concern. The thermal resistance of tempered glass also allows it to be used in environments exposed to high temperatures, such as oven doors and glass facades of buildings.

Moreover, tempered glass has excellent clarity and can be coated or tinted for aesthetic purposes. It can also be laminated for added safety or sound insulation, broadening its application potential. The ability to customize tempered glass for different uses without compromising its structural integrity is another reason for its popularity.

Applications of Tempered Glass

Tempered glass is used in a wide array of industries, including construction, automotive, and appliances. In residential and commercial buildings, tempered glass is utilized in windows, curtain walls, and facades due to its safety features and aesthetic appeal. In the automotive sector, tempered glass is commonly used for side and rear windows as it offers enhanced protection for passengers.

Moreover, tempered glass is an integral part of everyday appliances like stovetops and ovens, where it can withstand heat and thermal stress. The evolving design trends also see tempered glass being employed in furniture and decorative elements, merging style with functionality.

Conclusion

The process of making tempered glass involves meticulous steps that yield a product known for its superior strength and safety. Through the combination of heating and rapid cooling, glass transforms into a durable material suitable for diverse applications. As industries continue to innovate, the demand for tempered glass is likely to grow, paving the way for new uses and advancements in design. Whether in architecture, automotive design, or home appliances, tempered glass stands out as a testament to engineering excellence, underscoring its significance in modern society.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu